(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

TRUSCO Ball Rollers(Ball Material:Plastic)

TRUSCO offers products Ball Rollers specified by Ball Material Plastic from Automation Components product category. There are a total of 2 items. Search and select detailed specifications of parts for your machine with free CAD downloads. TRUSCO products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Load Capacity(N)

- 1

- 2

- 4

- 4.9

- 5

- 6

- 7

- 8

- 8.8

- 9.8

- 10

- 11

- 12

- 14

- 14.7

- 19.6

- 19.62

- 21

- 23

- 24

- 27

- 29.4

- 30

- 33

- 34

- 41

- 44 (4.5)

- 49

- 49.05

- 49.6 (5)

- 50

- 55

- 62

- 68

- 68.6

- 69

- 78

- 78.4

- 78.48

- 78.5

- 82

- 98

- 98.1

- 107

- 107.8

- 117.6 (12)

- 147

- 157

- 176

- 196

- 196.1

- 196.2

- 216

- 245

- 274 (28)

- 274.4 (28)

- 284

- 294

- 294.2

- 294.3

- 330 (34)

- 343

- 370

- 392

- 412

- 432

- 461

- 470.4 (48)

- 490

- 490.3

- 490.5

- 510

- 528

- 588

- 588.6

- 648

- 686

- 686.4

- 730

- 770

- 784

- 784.5

- 784.8

- 864

- 882

- 900

- 980

- 981

- 1020

- 1038

- 1056

- 1070

- 1080

- 1176

- 1176 (120)

- 1176.8

- 1180

- 1210

- 1296

- 1372

- 1470

- 1470.6

- 1471.5

- 1510

- 1512

- 1528

- 1530

- 1550

- 1568

- 1570

- 1610

- 1728

- 1764

- 1910

- 1944

- 1960

- 1962

- 2040

- 2160

- 2200

- 2292

- 2320

- 2376

- 2401

- 2420

- 2450

- 2451.66

- 2548

- 2550

- 2592

- 2640

- 2646

- 2704

- 2744

- 2800

- 2940

- 2943

- 2992

- 3020

- 3024

- 3056

- 3060

- 3090

- 3240

- 3380

- 3430

- 3438

- 3456

- 3528

- 3570

- 3630

- 3672

- 3680

- 3820

- 3870

- 3880

- 3920

- 4080

- 4104

- 4116

- 4202

- 4275

- 4320

- 4410

- 4500

- 4530

- 4536

- 4584

- 4590

- 4640

- 4732

- 4752

- 4830

- 4900

- 4905

- 4968

- 5100

- 5150

- 5184

- 5348

- 5390

- 5400

- 5408

- 5420

- 5610

- 5616

- 5730

- 5832

- 5880

- 6040

- 6048

- 6084

- 6120

- 6264

- 6468

- 6480

- 6620

- 6696

- 6750

- 6912

- 7056

- 7130

- 7350

- 7550

- 7640

- 7650

- 8090

- 8112

- 8150

- 8660

- 8788

- 8820

- 9060

- 9120

- 9170

- 9464

- 9560

- 9680

- 9800

- 10080

- 10140

- 10300

- 10600

- 11000

- 11760

- 11800

- 12100

- 12500

- 13200

- 13600

- 14000

- 14700

- 14872

- 15100

- 16600

- 18100

- 19600

- 21100

- 22600

- 24100

- 25700

- 27200

- 28700

- No

-

Shape

-

Type

-

Outer Dia. D(Ø)

- 8

- 9

- 10

- 11

- 12

- 12.2

- 13

- 15

- 15.8

- 16

- 16.5

- 17

- 18

- 18.5

- 19

- 19.2

- 19.5

- 20

- 20.5

- 21

- 22

- 23

- 24

- 24 ±0.065

- 25

- 25.7

- 25.8

- 26

- 27

- 27.5

- 28

- 29

- 29.5

- 30

- 31

- 32

- 33

- 34

- 34.4

- 34.5

- 35

- 35.8

- 36

- 38

- 39

- 39.5

- 41

- 41.3

- 42

- 44

- 44.5

- 45

- 46

- 47

- 47.5

- 48

- 50

- 50.2

- 51

- 51.5

- 52

- 53

- 55

- 55.5

- 55.8

- 56

- 57

- 58

- 59.3

- 60

- 65

- 65.2

- 66

- 67

- 69

- 70

- 71

- 71.8

- 72

- 75

- 76

- 77

- 78

- 80

- 85

- 88

- 95

- 96

- 96.8

- 100

- 107

- 110

- 120

- 130

- 140

- 151.2

- 155

- 160

- 180

- 187

- 200

- 304

- 401

- 456

- No

-

Load Capacity Range(N)

- 1.0~10.0

- 10.1~20.0

- 20.1~50.0

- 50.1~100.0

- 100.1~500.0

- 500.1~5000

- 5000.1~10000

- 10000.1~20000

- 20000.1 or more

-

Body Material

- Steel

- Stainless Steel

- Plastic

- Aluminum

-

Ball Material

- Steel

- Stainless Steel

- Plastic

Brand |

|

|---|---|

| CAD |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

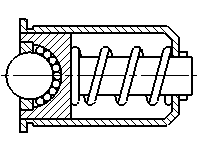

Until 31/03/2025Ball Casters for upturn of the ball

TRUSCO

- Ball Casters for ball upturn, manufactured by TRUSCO.

- Ball Casters are available in six types: S8B, S8P, T5L5B, T8LB, U8B, and U8P.

- The body material can be selected from two types: steel or stainless steel (SUS304).

- The ball material can be selected from three types: steel, stainless steel (SUS304), and polypropylene (PP).

- The load capacity of the ball transfer can be selected at two levels: 78.4 N or 294 N.

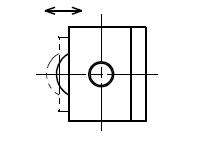

- Flange-shaped ball caster for upward movement.

- The transfer height can be selected at two levels: 20 mm or 31 mm.From: ฿ 196.00 Special Price Days to Ship: 1 Day(s)

1 Day(s)

-

You can add up to 6 items per a category to the compare list.

TRUSCO

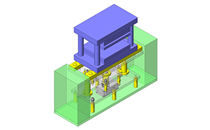

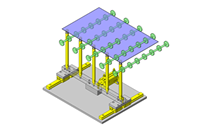

- U-8B (P) X Ball Conveyor from TRUSCO.

- The ball casters are manufactured using durable steel material.

- The ball caster is a resin type designed to minimize noise and provide scratch resistance.

- The ball conveyor is specifically designed for upward ball movement.

- You can choose from two types of ball materials: Steel (U8B type) and Polypropylene (U8P type).

- The pitch of the ball transfer can be selected in two options: 75 mm or 100 mm.

- The dimensions of the ball conveyor are as follows: width 77 mm, height 71 mm.

- The length of the ball conveyor is available in four sizes: 450 mm, 600 mm, 750 mm, and 900 mm.From: ฿ 3,948.00 Days to Ship: 1 Day(s)

1 Day(s)

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Load Capacity(N) |

| Shape |

| Type |

| Outer Dia. D(Ø) |

| Load Capacity Range(N) |

| Body Material |

| Ball Material |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | TRUSCO | TRUSCO |

| Product Series | ||

| From | ฿ 196.00 Special Price On Sale Until 31/03/2025 | ฿ 3,948.00 |

| Days to Ship | 1 Day(s) | 1 Day(s) |

| Load Capacity(N) | 294 | 294 |

| Shape | Flange | Unit |

| Type | Standard | Standard |

| Outer Dia. D(Ø) | 42 | 69 |

| Load Capacity Range(N) | 100.1~500.0 | 100.1~500.0 |

| Body Material | Steel / Stainless Steel | Steel |

| Ball Material | Plastic | Plastic |

Loading...

Application example related to this category

Related Categories to Ball Rollers

FAQ Ball Rollers

- Question: What is a ball roller and how does it work?

- Answer: A ball roller , also known as a ball transfer unit, is a device used in material handling applications to facilitate the movement of objects. It consists of multiple small ball bearings held within a housing. The balls are designed to rotate freely, allowing objects to be smoothly transferred or rotated in any direction.

- Question: What are the advantages of using ball rollers in material handling applications?

- Answer: Ball roller offer several advantages in material handling applications. They provide a low-friction surface, enabling easy and smooth movement of objects. Ball transfers allow for multidirectional movement, making them suitable for applications that require quick and efficient changes in direction. They are also durable, capable of handling heavy loads, and can be easily integrated into conveyor systems or workstations.

- Question: How do you select the right type of ball roller for your specific application?

- Answer: When selecting a ball roller , consider factors such as the weight and size of the objects being transferred, the operating environment, and the desired movement flexibility. It is important to choose a ball transfer with a load capacity that meets your application requirements. Consulting with a supplier or engineer can help determine the appropriate type and specifications for your specific needs.

- Question: What are the different materials used to make ball rollers and how do they affect performance?

- Answer: Ball roller can be made from various materials, including steel, stainless steel, and plastic. Steel ball transfers offer high load capacity and durability, making them suitable for heavy-duty applications. Stainless steel transfers are corrosion-resistant and ideal for environments with moisture or harsh chemicals. Plastic transfers are lightweight and non-corrosive, suitable for lighter loads and quieter operation. The choice of material depends on factors such as load capacity, operating conditions, and specific application requirements.

How can we improve?

How can we improve?