(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

THK Standard Linear Guides(Accuracy:High Grade)

Configure

Specification/Dimensions

-

Rail Length L(mm)

- 25

- 35

- 39

- 40

- 45

- 50

- 55

- 70

- 75

- 80

- 85

- 95

- 100

- 110

- 115

- 120

- 130

- 140

- 145

- 150

- 155

- 160

- 170

- 175

- 190

- 195

- 200

- 215

- 220

- 230

- 235

- 245

- 260

- 270

- 275

- 280

- 290

- 295

- 310

- 320

- 340

- 345

- 350

- 360

- 370

- 390

- 395

- 400

- 420

- 430

- 440

- 445

- 460

- 470

- 495

- 510

- 520

- 550

- 580

- 590

- 595

- 600

- 630

- 640

- 645

- 670

- 680

- 695

- 700

- 760

- 820

- 840

- 880

- 920

- 940

- 1000

- 1060

- 1080

- 1120

- 1160

- 1180

- 1240

- 1300

- 1320

- 1360

- 1400

- 1420

- 1480

- 1540

- 1560

- 1600

- 1640

- 1660

- 1720

- 1780

- 1800

- 1840

- 1880

- 1900

- 1960

[32-3000/1mm Unit(s)]

-

Block Type

-

Standard

Standard -

Short

Short -

Wide

Wide -

Wide Long

Wide Long -

Long

Long -

Extra Long

Extra Long -

Wide Short

Wide Short

-

-

Rail Width(mm)

-

Mounting Height H(mm)

-

Nominal Part Number

-

Rail Type

-

Standard

Standard -

Wide

Wide

-

-

Set / Single Item

- Set

- Block Only

- Rail Only

-

Preload

- Standard

- Light Preload

- Medium Preload

- Clearance

- Heavy Preload

See the accuracy standard of each manufacturer.

-

Accuracy

- Standard Grade

- High Grade

- Precision Grade

- High Precision Grade

- Ultra Precision Grade

See the accuracy standard of each manufacturer.

-

Material

-

Ball Arrangement

-

No. of Blocks

-

Retainer

-

Block Mounting Hole Pitch (Width Direction)(mm)

-

Block Mounting Hole Pitch (Length Direction)(mm)

-

Block Mounting Hole Diameter

-

Rail Mounting Hole Pitch(mm)

-

Rail Mounting Hole Diameter

Brand |

|

|---|---|

| CAD |

|

- 9 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

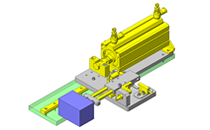

Full-Ball Type LM Guide, International Standard, HSR Type

THK

An international-standard sized LM guide that can be used from all positions.

[Features]

· Each of the ball raceways have been positioned at a 45° contact angle so that the rated load will be the same in all 4 directions (radial direction, reverse radial direction, horizontal directions) that act on the LM block,

allowing it to be used from any position and in a broad range of applications.

· The well-balanced 4-raceway configuration ensures a sufficient preload is applied, allowing you to increase rigidity in 4 directions with ease.

· The self-aligning capability achieved from THK's proprietary circular arched-groove front face assembly (DF set)

makes it possible to absorb any mounting error, even when there is a preload. It also delivers a smooth linear motion at high accuracies.

· With no differential slipping of the balls in relation to any preload or eccentric loads, ensuring smooth operation. Also, its excellent abrasion-resistance ensures accuracy over a long period.

· The LM block, LM rail and balls are all available in stainless steel.

· The balls are retained by the retaining plate without falling even when the LM rails are removed. (Excludes the HSR8, 10 and 12).Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

Caged Ball LM Guide, Miniature, SRS Type

THK

A miniature type with a compact structure. Can be mounted in areas where space is at a premium. Part of the LM block is made of resin for a lighter overall weight.

[Features]

· The adoption of the ball retainer has eliminated mutual friction between the balls, providing excellent high speed characteristics, low noise, good sound quality and a long lifespan, and keeps it maintenance-free for an extended period.

· The ball retainer eliminates mutual friction between the balls, improving how well the grease is maintained and reducing the amount of dust raised.

· The LM block and LM rail are both made with highly rust-preventive stainless steel.

· The rail cross-section height is kept low, and it has a compact structure with a single ball row on the right and left, allowing it to be mounted in areas where space is at a premium.

· A lightweight and low-inertia type where part of the LM block (around the ball escape hole, etc.) has been molded with resin using insert molding.

[Applications]

· Surface grinders,electric discharge machining, high-speed conveyors, NC lathes, injection molding machines

· Woodworking machines, semiconductor manufacturing devices, inspection devices, food processing machineryDays to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

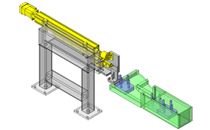

Caged Ball LM Guide, International Standard, SHS Type

THK

Each of the ball rows are arranged at a contact point of 45°, allowing the guide to be used with any posture

[Features]

· The adoption of the ball retainer has eliminated mutual friction between the balls, providing excellent high speed characteristics, low noise, good sound quality and a long lifespan, and keeps it maintenance-free for an extended period.

· The ball retainer eliminates mutual friction between the balls, improving how well the grease is maintained and reducing the amount of dust raised.

· Each of the ball raceways have been positioned at a 45° contact angle so that the rated load will be the same in all 4 directions (radial direction, reverse radial direction, horizontal directions) that act on the LM block, allowing it to be used from any position and in a broad range of applications.

· The self-aligning capability achieved from THK's proprietary circular arched-groove front face assembly (DF set) makes it possible to absorb any mounting error, even when there is a preload. It also delivers a smooth linear motion at high accuracies.

· Developed by THK, a pioneer of linear motion systems, it features a dimensional design that conforms to the full-ball type LM guide HSR type, the de-facto global standard.

· The cross-section of the LM rail has been made more compact, lowering the center of gravity and further increasing rigidity.

[Applications]

· Surface grinders,electric discharge machining, high-speed conveyors, NC lathes, injection molding machines

· Woodworking machines, semiconductor manufacturing devices, inspection devices, food processing machineryDays to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

Full-Ball Type LM Guide, Radial Type, SR Model

THK

Compact design with low cross-sectional height and ideal for horizontal guides.

[Features]

· Compact type with a low cross-sectional height, which is ideal for horizontal guide parts for ball contact structures that are strong against loads in the radial direction.

· Self-aligning type that can easily absorb error in the level accuracy and the degree of parallelism for the 2 shafts, which is capable of highly accurate and smooth movements.

· The retainer part on each of the ball rows can obtain rolling motions with limited sound because the balls are designed for smooth circulation using the guiding part on the end plate.

· Accuracy is possible to be maintained for long periods of time, has excellent abrasion-resistance and limited differential slipping even when there is a preload or uneven load.

· LM block, LM rail, and ball are all compatible with stainless steel.

· The ball will not fall out even if the LM block is removed from the LM rail because it is held by a holding plate.Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

Miniature Full-Ball Type LM Guide SRS-G Type

THK

Lightweight and compact structure.

[Features]

· The LM block is designed to ensure rigidity within a limited space.

· Combining with large diameter balls can provide rigidity in each direction.

· Capable of receiving loads in all directions, and a single-rail guide can adequately operate under a small moment load.

· Despite its compact-size, it is a finite stroke type of cross roller guide and ball slide.

· A highly reliable and compact linear motion system with no problematic cage misalignment.

· LM block, LM rail, and ball are all compatible with stainless steel.Days to Ship: 17 Day(s)

17 Day(s)

-

You can add up to 6 items per a category to the compare list.

Full-Ball Type LM Guide Wide Rail HRW Type

THK

A structure with a wide rail and low center of gravity. It is thinner than HSR and is advantageous when Mc moment stiffness is required.

[Features]

· LM rails and LM blocks feature 4 precision-ground raceways that the balls travel along. The end plates embedded in the LM block circulate the rows of balls.

· Compact heavy load: A high number of effective balls makes it possible to obtain high rigidity in all directions. Has a wide rail width and can adequately withstand moments with a single shaft.

There is a high rigidity in the horizontal direction and there is no need of reinforcement such as horizontal pressing due to large secondary moments being incurred on the rail cross-section.

· The self-aligning capability: The self-adjusting power effect of the front-facing combination (DF set) of unique circular arc groove allows to absorb mounting errors even if preload is applied, resulting in highly accurate, smooth linear motion.Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

Ball LM guide, radial type, SR-M1 type

THK

High temperature specifications that can be used in maximum temperatures of 150°C, and the grease can also be used in high temperature environments. Has low rolling resistance fluctuation in response to changes in temperature and a dimension consistency treatment has been applied, which has provided excellent dimensional consistency.Days to Ship: 37 Day(s)

37 Day(s)

-

You can add up to 6 items per a category to the compare list.

Caged Ball LM Guide Low Floor Wide Rail SHW Type

THK

A structure with a wide rail and low center of gravity. Thinner than the SHS type, which is advantageous when Mc moment rigidity is required.

[Features]

· A highly rigid LM guide with superior high speed performance and that is maintenance-free over long periods of time. Also generates little noise thanks to the adoption of a ball retainer.

· The SHW, which has a structure with a wide LM rail and a low center of gravity, is ideal for use in locations where there are space limitations or when there are MC moment rigidity requirements.

· Each of the ball raceways have been positioned at a 45° contact angle so that the rated load will be the same in all 4 directions (radial direction, reverse radial direction, horizontal directions) that act on the LM block, allowing it to be used from any position and in a broad range of applications.

· The self-aligning capability achieved from the manufacturer's proprietary circular arched-groove front face assembly (DF set) makes it possible to absorb any mounting error, even when there is a preload. It also delivers a smooth linear motion at high accuracies.

· The ball retainers eliminate friction generated by the balls rubbing against each other, while the lubricant oil (agent) is maintained, providing superior low-dust performance.Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

LM guide with Ball retainer - Limited stroke EPF type

THK

A limited stroke type. Smooth movement due to there being no ball circulation. Also has a high rigidity compared with conventional products from a structural standpoint. It is particularly advantageous when there are Mc moment requirements.Days to Ship: 22 Day(s)

22 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Rail Length L(mm) |

| Block Type |

| Rail Width(mm) |

| Mounting Height H(mm) |

| Nominal Part Number |

| Rail Type |

| Set / Single Item |

| Preload |

| Accuracy |

| Material |

| Ball Arrangement |

| No. of Blocks |

| Retainer |

| Block Mounting Hole Pitch (Width Direction)(mm) |

| Block Mounting Hole Pitch (Length Direction)(mm) |

| Block Mounting Hole Diameter |

| Rail Mounting Hole Pitch(mm) |

| Rail Mounting Hole Diameter |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | THK | THK | THK | THK | THK | THK | THK | THK | THK |

| Product Series | |||||||||

| CAD |

|

|

|

|

|

|

|

|

|

| From | |||||||||

| Days to Ship | 12 Day(s) | 12 Day(s) | 12 Day(s) | 12 Day(s) | 17 Day(s) | 12 Day(s) | 37 Day(s) | 12 Day(s) | 22 Day(s) |

| Rail Length L(mm) | 203 ~ 3000 | 32 ~ 2000 | 71 ~ 3000 | 73 ~ 3000 | 32 ~ 2000 | 72 ~ 3000 | 47 ~ 1500 | 108 ~ 3000 | 33 ~ 110 |

| Block Type | Standard / Wide | Standard / Wide / Long | Standard / Wide | Wide Short | Standard / Wide | Wide | Standard / Wide / Wide Short | Wide | Standard |

| Rail Width(mm) | 63 | 9 ~ 42 | 15 ~ 28 | 23 | 9 ~ 24 | 37 ~ 42 | 15 ~ 34 | 69 | 7 ~ 15 |

| Mounting Height H(mm) | 90 | 9 ~ 20 | 24 ~ 42 | 33 | 10 ~ 16 | 21 ~ 27 | 24 ~ 48 | 35 | 8 ~ 16 |

| Nominal Part Number | 65 | 7W ~ 20 | 15 ~ 30 | 25 | 9X ~ 15 | 21 ~ 27 | 15 ~ 35 | 35 | 7 ~ 15 |

| Rail Type | Standard | Standard / Wide | Standard | Standard | Standard / Wide | Wide | Standard | Wide | Standard |

| Set / Single Item | Set | Set | Set | Set | Set | Set | Set | Set | Set |

| Preload | Standard / Light Preload / Medium Preload | Standard / Light Preload | Standard / Light Preload / Medium Preload | Standard / Light Preload / Medium Preload | Standard / Light Preload | Standard / Light Preload | Standard / Light Preload / Medium Preload | Standard / Light Preload / Medium Preload | - |

| Accuracy | High Grade | High Grade | High Grade | High Grade | High Grade | High Grade | High Grade | High Grade | High Grade |

| Material | Carbon Steel | Stainless Steel | Carbon Steel | Carbon Steel | Stainless Steel | Carbon Steel / Stainless Steel | Stainless Steel | Carbon Steel | Stainless Steel |

| Ball Arrangement | 4-Row, Circular | Standard | 4-Row, Circular | 4-Row, Circular | Standard | 4-Row, Circular | 4-Row, Circular | 4-Row, Circular | 4-Row, Circular |

| No. of Blocks | 1 ~ 9 | 1 ~ 9 | 1 ~ 9 | 1 ~ 9 | 1 ~ 9 | 1 ~ 9 | 1 ~ 9 | 1 ~ 9 | 1 |

| Retainer | N/A | Available | Available | N/A | N/A | N/A | N/A | Available | Available |

| Block Mounting Hole Pitch (Width Direction)(mm) | 35 ~ 142 | 15 ~ 45 | 26 ~ 72 | 60 | 15 ~ 28 | 46 ~ 60 | 26 ~ 82 | 107 | 12 ~ 25 |

| Block Mounting Hole Pitch (Length Direction)(mm) | 70 ~ 120 | 10 ~ 35 | 26 ~ 52 | - | 10 ~ 20 | 29 ~ 32 | 26 ~ 50 | 60 | 13 ~ 25 |

| Block Mounting Hole Diameter | 16 | 3 ~ 4 | 4 ~ 8.5 | 7 | 3 | 4.4 ~ 6 | 4 ~ 9 | 8 | 2 ~ 3 |

| Rail Mounting Hole Pitch(mm) | 150 | 20 ~ 60 | 60 ~ 80 | 60 | 20 ~ 40 | 50 ~ 60 | 60 ~ 80 | 80 | 15 ~ 40 |

| Rail Mounting Hole Diameter | 18 | 3.5 ~ 6 | 4.5 ~ 9 | 7 | 3.5 ~ 4.5 | 4.5 | 3.5 ~ 9 | 7 | 2.4 ~ 3.5 |

Loading...

Related Categories to Standard Linear Guides

FAQ linear guide

- Question: What are standard linear guides?

- Answer: Standard linear guides come in different configurations, such as:

1. Profiled Rail Guides: These linear guides have a rectangular-shaped rail with a corresponding carriage. They provide high load capacity and stiffness, making them suitable for applications that require precision and rigidity.

2. Round Rail Guides: These linear guides feature a round rail and a carriage with circular-shaped rolling elements. They offer smooth and quiet motion and are commonly used in applications with lower load capacities.

3. Compact Linear Guides: These linear guides are designed to have a smaller footprint and are suitable for applications with limited space. They often feature ball bearing-based systems and are used in various industries, including automation and robotics - Question: How do standard linear guides work?

- Answer: Standard linear guides, also known as linear motion systems are mechanical devices used to provide smooth and precise linear motion in various applications. Here's a short explanation of how they work

1. Rail and Slide block: A standard linear guide consists of two main components: a rail and a slide block. The rail is a long, straight and rigid structure that serves as a guide for the linear motion. The slide block is a movable component that rides along the rail.

2. Rolling Elements: Inside the slide block, there are ball rolling. These elements reduce friction, enable smooth motion along the rail and distribute the load evenly across the rail,

3. Lubrication: Some linear guides require lubrication to further reduce friction and ensure smooth operation. Lubricants can be applied to the bearing surfaces or be pre-lubricated within the slide block.

4. Mounting: Linear guides are usually mounted to a stationary base or structure, and the slide block is connected to the moving part or load that needs linear motion. - Question: What industries use standard linear guides?

- Answer: Standard linear guides, which provide precise linear motion control, are utilized in several industries such as

1. Manufacturing and Automation: These kinds of industries widely employ standard linear guides for accurate linear motion control in machine tools, assembly lines, conveyors, and robotic systems

2. Electronics and Semiconductor Industries: The semiconductor and electronics industries rely on linear guides for precise linear motion in equipment such as wafer handling systems, semiconductor manufacturing machines, electronic assembly lines, and so on

3. Medical Industries: Linear guides are used in medical and laboratory equipment for precise linear motion control in kinds of these machines such as surgical robots, measurement tools, and laboratory automation.

4. Printing industry: The printing industry utilizes linear guides to facilitate precise linear motion control in printing machinery systems such as paper handling systems, and paper converting equipment, ensuring high-quality printing and accurate paper handling. - Question: What are the benefits of using standard linear guides?

- Answer: By using standard linear guides offers several benefits in applications requiring precise linear motion control.

1. Precise Linear Motion Control

2. Smooth and Low-Friction Operation

3. High Load-Carrying Capacity

4. Repeatability and Positioning Accuracy

5. Enhanced System Stability

6. Durability and Longevity

7. Versatile and Customizable

8. Wide Range of Applications By utilizing standard linear guides, users can achieve precise, smooth, and reliable linear motion control in their designs, enhancing system performance, accuracy, and overall productivity in numerous applications. - Question: How to select the right standard linear guide for a specific application?

- Answer: Selecting the right standard linear guide for a specific application involves considering various factors. Here's a short step by step for selecting the linear guide

1. Load Capacity: Determine the maximum load the linear guide needs to support in the application. Consider both static and dynamic loads to ensure the guide can handle the required weight.

2. Travel Distance: Evaluate the required travel distance or stroke length of the linear motion and range of motion without exceeding its limits.

3. Precision Requirements: Assess the level of precision needed for the application. Consider factors such as positioning accuracy, repeatability, and smoothness of motion.

4. Speed and Acceleration: Determine the desired speed and acceleration of the linear motion.

5. Environmental Factors: Consider factors such as temperature, humidity, dust, and exposure to chemicals.

6. Mounting and Integration: Consider the mounting options and requirements for integrating the linear guide into the application.

7. Maintenance and Lubrication: Consider factors such as ease of maintenance, lubrication intervals, and access to lubrication points.

8. Budget and Cost Considerations: Evaluate the budget available for the linear guide

9. Consult Manufacturer's Recommendations: Review the manufacturer's specifications, guidelines, and recommendations for the specific linear guide models.

How can we improve?

How can we improve?