(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

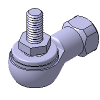

STRUENING Rod End Bearings, Spherical Bearings(Ball Material:Steel)

STRUENING offers products Rod End Bearings, Spherical Bearings specified by Ball Material Steel from Automation Components product category. There are a total of 1 items. Search and select detailed specifications of parts for your machine with free CAD downloads. STRUENING products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Rod End Bearing Type

-

Standard

Standard -

Link Ball L

Link Ball L -

Link Ball Straight

Link Ball Straight

-

-

Connecting Screw M

-

Spherical Bearing Type

-

Standard

Standard -

Pillow Block A

Pillow Block A -

Flange Type, with 4 Holes

Flange Type, with 4 Holes -

With ball stud

With ball stud

-

-

Main Body Material

-

Connecting Thread Shape

- Threaded

- Tapped

-

Inner Dia. d(Ø)

-

Type

- Rod End Bearings

- Spherical Bearing

-

Connecting Thread Direction

- Right-hand Thread

- Left-hand Thread

-

Liner Material

-

Ball Material

-

Allowable Tilt Angle α(deg)

-

Lubrication Method

Brand |

|

|---|---|

| CAD |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

![Rod End Bearing, Link Bowl L Type [RTLBL]](//th.misumi-ec.com/en/linked/material/mech/TLZ1/PHOTO/221005202228.jpg?$product_view_b$)

Rod End Bearing, Link Bowl L Type [RTLBL]

STRUENING

A link ball L type rod end bearing. SB is a Taiwanese manufacturer that was established in 1989. Obtained ISO9001: 2000 certification in 2006 and continues to implement world-class quality standards. Sells products to companies all over the world and has a high share of the Asian, European, and North American markets. MISUMI supplies rod end bearings.From: ฿ 190.10 Days to Ship: 5 Day(s)

5 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Rod End Bearing Type |

| Connecting Screw M |

| Spherical Bearing Type |

| Main Body Material |

| Connecting Thread Shape |

| Inner Dia. d(Ø) |

| Type |

| Connecting Thread Direction |

| Liner Material |

| Ball Material |

| Allowable Tilt Angle α(deg) |

| Lubrication Method |

You can add up to 6 items per a category to the compare list. | |

| Brand | STRUENING |

| Product Series | |

| CAD |

|

| From | ฿ 190.10 |

| Days to Ship | 5 Day(s) |

| Rod End Bearing Type | - |

| Connecting Screw M | M5 / M6 / M8 / M10 / M12 / M14 / M16 |

| Spherical Bearing Type | - |

| Main Body Material | High Strength Zinc Alloy |

| Connecting Thread Shape | - |

| Inner Dia. d(Ø) | - |

| Type | Rod End Bearings |

| Connecting Thread Direction | - |

| Liner Material | - |

| Ball Material | Steel |

| Allowable Tilt Angle α(deg) | 35 ~ 45 |

| Lubrication Method | - |

Loading...

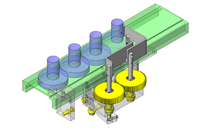

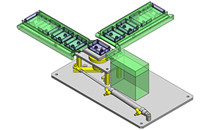

Application example related to this category

Related Categories to Rod End Bearings, Spherical Bearings

FAQ Rod End Bearings, Spherical Bearings

- Question: What is a rod end bearing?

- Answer: A rod end bearing, also known as a spherical bearing, is like the human body's ball-and-socket joint, engineered for machines. These bearings are crucial because they allow for smooth, precise, and multi-directional movements. They are used in various demanding environments such as:

- Aircraft systems (like landing gear and control linkages)

- Automotive suspensions where flexibility and durability are paramount

- Robotic arms for precise and fluid motion - Question: What are the types of rod end bearings available?

- Answer: Rod end bearings are designed in several configurations to meet specific application needs, including:

- Standard Type: Ideal for general-purpose applications, robust and versatile.

- Short Type: Best for setups where space is at a premium.

- Link Ball (L-shaped & Straight): These provide unique mounting options for more complex or unconventional applications.

When selecting a type, consider the load capacity and thread direction to ensure compatibility and functionality in your setup. - Question: What materials are used in rod end bearings?

- Answer: Choosing the right material for your rod end bearing is critical for performance and longevity:

- S45C and Chrome Molybdenum Steel: Offers strength for heavy-duty applications.

- Aluminum: Light-weight option for applications where reducing mass is crucial.

- Stainless Steel: Excellent for resisting corrosion in harsh environments, such as marine applications.

Resins and High-Strength Alloys: These can reduce noise or offer resistance to chemicals.

Selecting the appropriate material ensures the bearing can withstand the operational environment without premature failure. - Question: What are the features of lubrication-free rod end bearings?

- Answer: Lubrication-free rod end bearings are engineered to reduce maintenance without sacrificing performance. Key features include:

- Maintenance Ease: No need for regular greasing, which means less downtime and a cleaner operation.

- Self-lubricating Materials: These bearings use advanced materials designed to reduce friction and wear naturally.

- Optional Lubrication Holes: For applications where additional lubrication might be necessary, enhancing flexibility in maintenance practices.

These bearings are especially useful in hard-to-reach areas or in environments where maintaining traditional lubrication routines is challenging. - Question: How do I select the right rod end bearing for my application?

- Answer: Selecting the right rod end bearing involves understanding the specific requirements of your application. Consider the following:

- Load Capacity: Ensure the bearing can handle the operational forces.

- Thread Direction: Match the thread type (right-hand or left-hand) with your assembly requirements.

- Material Compatibility: Choose a material that suits your environmental conditions to avoid issues like corrosion.

- Maintenance Requirements: Consider how often maintenance can be performed; opt for lubrication-free models if necessary.

Utilize tools like CAD downloads for virtual testing and consult manufacturer datasheets for detailed specifications. When in doubt, reaching out to a supplier for guidance can help ensure you choose the best component for your needs.

![Rod End Bearing, Link Bowl L Type [RTLBL]](http://th.misumi-ec.com/en/linked/material/mech/TLZ1/PHOTO/221005202228.jpg?$product_view_b$)

![Rod End Bearing, Link Bowl L Type [RTLBL]](http://th.misumi-ec.com/en/linked/material/mech/TLZ1/PHOTO/221005202228.jpg?$product_view_c$)

How can we improve?

How can we improve?