(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

RIKEN Screw Fittings, Screw-In Type Flanges(Material:Bronze)

RIKEN offers products Screw Fittings, Screw-In Type Flanges specified by Material Bronze from Automation Components product category. There are a total of 1 items. Search and select detailed specifications of parts for your machine with free CAD downloads. RIKEN products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Connecting Shape

-

Connection Type

- Thread <-> Thread, Equal Dia. Same Type

- Thread <-> Thread, Equal Dia. Different Type

- Thread <-> Thread, Unequal Dia.

- Thread <-> Steel Pipe

- Screws

- Thread <=> Flange

-

Material

- Stainless Steel

- Steel

- Brass

- Aluminum

- Resin

- Bronze

- Cast Iron

-

Nominal of Thread M1

-

Connection Thread Type M1

-

Connection Thread Type M2

-

Nominal of Thread M2

-

Applicable Fluid

- Water

- Air

- vapor

- Gas

- Chemical

- Oil

- Not specified by Manufacturer

-

Type

- Fitting

- Related Products

-

Max. Operating Pressure(MPa)

-

Surface Treatment

- Not Provided

- Trivalent Chromate

- Chrome Plating

- Nickel Plating

- Zinc Plating

- Black Oxide

- Painted

- Resin Coating

- Zinc Electroplating

-

Types of Screw 3 (When Different Dia. or Different Type Screw)

-

Nominal of Thread 3(Different Diameters or Different Type Screw)

-

Types of Screw 4 (When Different Dia. or Different Type Screw)

-

Nominal of Thread 4(Different Diameters or Different Type Screw)

-

Divisions of Max. Operating Pressure

- 1.0Mpa or Less

- 2.0Mpa or Less

- than 2.0Mpa

-

Types of Related components

- Valve

- Nut

- Hex Wrench

- Gasket

-

Interior Resin Lining

- Presence

- No

Brand |

|

|---|---|

| CAD |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Pipe-End Anticorrosion Fitting, RCF-K, for Fixture Connection, General, BC Nipple (Bronze)

RIKEN

Anticorrosion fitting for tube ends. Malleable iron fitting with an incorporated resin core.From: ฿ 459.23 Days to Ship: 11 Day(s)

11 Day(s)

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Connecting Shape |

| Connection Type |

| Material |

| Nominal of Thread M1 |

| Connection Thread Type M1 |

| Connection Thread Type M2 |

| Nominal of Thread M2 |

| Applicable Fluid |

| Type |

| Max. Operating Pressure(MPa) |

| Surface Treatment |

| Types of Screw 3 (When Different Dia. or Different Type Screw) |

| Nominal of Thread 3(Different Diameters or Different Type Screw) |

| Types of Screw 4 (When Different Dia. or Different Type Screw) |

| Nominal of Thread 4(Different Diameters or Different Type Screw) |

| Divisions of Max. Operating Pressure |

| Types of Related components |

| Interior Resin Lining |

You can add up to 6 items per a category to the compare list. | |

| Brand | RIKEN |

| Product Series | Pipe-End Anticorrosion Fitting, RCF-K, for Fixture Connection, General, BC Nipple (Bronze) |

| From | ฿ 459.23 |

| Days to Ship | 11 Day(s) |

| Connecting Shape | Nipple |

| Connection Type | Thread <-> Thread, Equal Dia. Same Type |

| Material | Bronze |

| Nominal of Thread M1 | 3/4B(20A) / 1 1/4B(32A) |

| Connection Thread Type M1 | R |

| Connection Thread Type M2 | - |

| Nominal of Thread M2 | - |

| Applicable Fluid | Water |

| Type | Fitting |

| Max. Operating Pressure(MPa) | 1 |

| Surface Treatment | Painted |

| Types of Screw 3 (When Different Dia. or Different Type Screw) | - |

| Nominal of Thread 3(Different Diameters or Different Type Screw) | - |

| Types of Screw 4 (When Different Dia. or Different Type Screw) | - |

| Nominal of Thread 4(Different Diameters or Different Type Screw) | - |

| Divisions of Max. Operating Pressure | 1.0Mpa or Less |

| Types of Related components | - |

| Interior Resin Lining | Presence |

Loading...

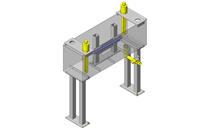

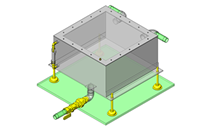

Application example related to this category

Related Categories to Screw Fittings, Screw-In Type Flanges

FAQ Screw Fittings, Screw-In Type Flanges

- Question: What are screw-in type flanges, and how are they used in industrial applications?

- Answer: Screw-in type flanges are fittings used to connect pipes, valves, or equipment in industrial piping systems securely. They feature threaded connections for easy installation and removal, ensuring leak-proof connections in various applications.

- Question: What materials are screw-in type flanges made of, and how does material choice affect their performance?

- Answer: Screw-in type flanges are available in materials such as stainless steel, carbon steel, and brass. Material choice influences factors like corrosion resistance, pressure handling capability, and compatibility with different fluids, impacting the overall performance and longevity of the flanges.

- Question: How's different between screw-in type flanges and other types such as weld neck flange or slip-on flanges?

- Answer: Screw-in type flanges, also known as threaded flanges, feature threaded connections for easy installation and removal, unlike weld neck or slip-on flanges, which require welding or slipping onto the pipe. Threaded flanges offer convenience and versatility in piping systems.

- Question: What are the advantages of using screw-in type flanges in piping systems?

- Answer: Screw-in type flanges provide several advantages, including ease of installation, versatility in connection methods, and compatibility with various pipe materials. They also allow for quick disassembly and reassembly, making maintenance and repairs more convenient.

- Question: Can screw-in type flanges withstand high-pressure environments?

- Answer: Yes, screw-in type flanges are designed to withstand high-pressure environments commonly found in industrial applications. The choice of material and proper installation ensure that these flanges maintain leak-proof connections even under high pressure.

- Question: Are screw-in type flanges suitable for use with different types of fluids?

- Answer: Yes, screw-in type flanges are compatible with various fluids commonly used in industrial applications, including water, oil, gas, and chemicals. However, it's essential to select flanges made from materials compatible with the specific fluid to prevent corrosion or degradation.

- Question: How to I select the right size of screw-in type flanges for my piping system?

- Answer: Choosing the right size of screw-in type flanges involves considering factors such as pipe diameter, pressure rating, and application requirements. Referencing industry standards and consulting with experts can help ensure the proper selection of flanges for your piping system.

- Question: Can resuse screw-in type flanges after disassembly?

- Answer: In many cases, screw-in type flanges can be reused after disassembly, provided they are in good condition and free from damage. Proper inspection and maintenance practices are essential to determine the suitability of reused flanges and ensure system integrity.

- Question: How do I prevent leaks in screw-in type flanges?

- Answer: To prevent leaks in screw-in type flanges, ensure proper installation, including adequate tightening of threaded connections and the use of appropriate sealing materials such as gaskets or thread sealants. Regular inspection and maintenance also help identify and address potential leakage issues.

- Question: Are there customization options available for screw-in type flanges to meet specific requirements?

- Answer: Yes, many suppliers offer customization options for screw-in type flanges, allowing for tailored solutions to meet specific size, material, or performance requirements. Discussing your needs with suppliers can help determine the best customization options for your application.

How can we improve?

How can we improve?