(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 28/7/2024 to 6:00 29/7/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

NSK Support Units(Type:Support Side)

NSK offers products Support Units specified by Type Support Side from Automation Components product category. There are a total of 1 items. Search and select detailed specifications of parts for your machine with free CAD downloads. NSK products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Shape

-

Square

Square -

Round

Round -

Round, 2 Set Screw Flats at both ends

Round, 2 Set Screw Flats at both ends

-

-

Shaft Dia. d(Ø)

-

Mounting Method

-

Bearing Type

- Angular Contact Bearing

- Radial Bearing, Single

- Radial Bearing, Double

-

Shaft Height H(mm)

-

Bearing Grade

-

Surface Treatment

- Black Oxide

- Electroless Nickel Plating

- Low Temperature Black Chrome Plating

- Not Provided

-

Thickness B(mm)

-

Width W(mm)

-

Support Material

-

Outer Dia. D(Ø)

|

Type

|

|

|---|---|

Brand |

|

Filter By |

|

| CAD |

|

| Days to Ship |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025Support Side Support Unit (Square) (for Small Size Equipment and Light Loads)

NSK

Uses a thrust angular ball bearing of high rigidity and high-accuracy having ideal structure and functionalityFrom: ฿ 2,071.70 Special Price Days to Ship: Same day

Same day

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Type |

| Shape |

| Shaft Dia. d(Ø) |

| Mounting Method |

| Bearing Type |

| Shaft Height H(mm) |

| Bearing Grade |

| Surface Treatment |

| Thickness B(mm) |

| Width W(mm) |

| Support Material |

| Outer Dia. D(Ø) |

You can add up to 6 items per a category to the compare list. | |

| Brand | NSK |

| Product Series | Support Side Support Unit (Square) (for Small Size Equipment and Light Loads) |

| From | ฿ 2,071.70 Special Price On Sale Until 31/03/2025 |

| Days to Ship | Same day |

| Type | Support Side |

| Shape | Square |

| Shaft Dia. d(Ø) | 6 ~ 25 |

| Mounting Method | Face Mounting |

| Bearing Type | Angular Contact Bearing |

| Shaft Height H(mm) | 17 ~ 35 |

| Bearing Grade | Grade 4 |

| Surface Treatment | Black Oxide / Low Temperature Black Chrome Plating |

| Thickness B(mm) | 15 ~ 30 |

| Width W(mm) | 52 ~ 105 |

| Support Material | Steel |

| Outer Dia. D(Ø) | - |

Loading...

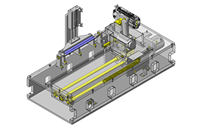

Application example related to this category

Related Categories to Support Units

FAQ Support Units

- Question: What are support units for ball screws?

- Answer: Support units are essential components designed to provide support and stability for ball screws in various applications. They ensure the precise positioning and smooth operation of the screw shaft by using integrated bearings. These units are crucial for maintaining the alignment and reducing the load on the screw shaft, which enhances the overall performance and longevity of the system.

- Question: What types of support units are available?

- Answer: Support units come in different shapes and configurations to suit various applications. The main types include:

Fixed Side Support Units (Models BK, EK, FK): These units are typically used on the motor side and include angular contact bearings with pre-adjusted preload for high rigidity and accuracy.

Support Side Support Units (Models BF, EF, FF): These units use deep-groove ball bearings and are designed to support the opposite end of the ball screw from the motor. - Question: How do I choose the right support unit for my application?

- Answer: When selecting a support unit, consider the following factors:

Load Requirements: Determine the axial and radial loads the unit will need to handle. High-load applications typically require units with angular contact bearings.

Speed Requirements: For high-speed applications, choose units designed for high rotational speeds.

Space Constraints: Select the shape and size (square or round) that best fits the available installation space.

Accuracy Needs: Ensure the support unit's precision matches the requirements of your application, especially for high-precision tasks. - Question: What are the benefits of using angular contact bearings in support units?

- Answer: Angular contact bearings are designed to handle both radial and axial loads with high rigidity and low torque. They are ideal for applications requiring high precision and stability, such as in CNC machinery and robotics. These bearings help maintain the alignment and smooth operation of the ball screw, reducing wear and increasing the system's lifespan.

- Question: Can support units be used in high-speed applications?

- Answer: Yes, certain support units are specifically designed for high-speed applications. For instance, the FK series incorporates bearings that can handle high rotational speeds and maintain stability. It is crucial to select support units that specify high-speed capabilities to ensure optimal performance.

- Question: How do I install a support unit correctly?

- Answer: Installation involves securing the support unit to the machine frame and ensuring the ball screw is properly aligned. Follow these steps:

Mounting: Attach the support unit using appropriate fasteners and ensure it is securely fixed to the frame.

Alignment: Align the ball screw with the support unit's bearing to avoid misalignment and uneven load distribution.

Preload Adjustment: For units with pre-adjusted preload bearings, no additional adjustment is necessary. Ensure the preload is correct to maintain system accuracy and rigidity. - Question: What maintenance is required for support units?

- Answer: Support units generally require minimal maintenance. However, periodic checks and maintenance can help extend their lifespan:

Lubrication: Ensure the bearings are properly lubricated. Some units come pre-lubricated and sealed for long-term use.

Inspection: Regularly inspect for signs of wear, such as noise, vibration, or increased play in the bearings.

Cleaning: Keep the units clean and free from debris that can affect performance. - Question: What are common applications for support units?

- Answer: Support units are used in a wide range of applications, including:

CNC Machinery: Provides precision and stability for machining operations.

Robotics: Ensures accurate and smooth movement in robotic arms and systems.

Medical Equipment: Used in devices requiring high precision and reliability.

Industrial Automation: Supports various automated systems where precise motion control is necessary.

How can we improve?

How can we improve?