(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

MINEBEA Rod End Bearings, Spherical Bearings(Connecting Screw M:M8)

Configure

Specification/Dimensions

-

Rod End Bearing Type

-

Standard

Standard -

Link Ball L

Link Ball L -

Link Ball Straight

Link Ball Straight

-

-

Connecting Screw M

-

Spherical Bearing Type

-

Standard

Standard -

Pillow Block A

Pillow Block A -

Flange Type, with 4 Holes

Flange Type, with 4 Holes -

With ball stud

With ball stud

-

-

Main Body Material

-

Connecting Thread Shape

- Threaded

- Tapped

-

Inner Dia. d(Ø)

-

Type

- Rod End Bearings

- Spherical Bearing

-

Connecting Thread Direction

- Right-hand Thread

- Left-hand Thread

-

Liner Material

-

Ball Material

-

Allowable Tilt Angle α(deg)

-

Lubrication Method

Brand |

|

|---|---|

| CAD |

|

- 3 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Rod End Bearing, Left Male Screw, fluoropolymer Type, Two Pieces RBTL-E

MINEBEA

Comprised of a ball and body. The body is formed (or swaged) around the ball. The body material is made from cold-formed 303 stainless steel. This bearing has a lower load bearing capacity than the 3 piece and 4 piece rod end bearings. Its low production cost and simple construction make it suitable to applications for general industrial machinery. The rod end requires no lubrication, and is made of stainless steel (303 for the body, 440C for the ball), giving it excellent anti-corrosion characteristics so it can be used in a wide range of general purpose applications.From: ฿ 747.43 Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

Rod End Bearing, Right-Hand Male Thread, fluoropolymer Type 3 Piece HRT-E

MINEBEA

Comprised of a spherical bearing placed into the rod end body. The main body is made of materials such as include chrome molybdenum steel. The product features a strong body with a hardness of HRC35 and a tensile strength of 980 N/mm2 or more. The 3-piece rod end is widely used in places with extreme performance requirements as a suitable spherical lathe material can be selected depending on the application.From: ฿ 1,768.02 Days to Ship: 6 Day(s)

6 Day(s)

-

You can add up to 6 items per a category to the compare list.

Rod End BearingRight Female Screwfluoropolymer TypeThree Pieces HRT

MINEBEA

Comprised of a spherical bearing placed into the rod end body. The main body material is chrome molybdenum steel which has a hardness of HRC35 and tensile strength of 980N/mm2 or more. The 3-piece rod end is widely used in places with extreme performance requirements. The spherical race material can be selected to suit the application.From: ฿ 1,853.60 Days to Ship: 5 Day(s)

5 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Rod End Bearing Type |

| Connecting Screw M |

| Spherical Bearing Type |

| Main Body Material |

| Connecting Thread Shape |

| Inner Dia. d(Ø) |

| Type |

| Connecting Thread Direction |

| Liner Material |

| Ball Material |

| Allowable Tilt Angle α(deg) |

| Lubrication Method |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MINEBEA | MINEBEA | MINEBEA |

| Product Series | Rod End Bearing, Left Male Screw, fluoropolymer Type, Two Pieces RBTL-E | Rod End Bearing, Right-Hand Male Thread, fluoropolymer Type 3 Piece HRT-E | Rod End BearingRight Female Screwfluoropolymer TypeThree Pieces HRT |

| CAD |

|

|

|

| From | ฿ 747.43 | ฿ 1,768.02 | ฿ 1,853.60 |

| Days to Ship | 12 Day(s) | 6 Day(s) | 5 Day(s) |

| Rod End Bearing Type | Standard | Standard | Standard |

| Connecting Screw M | M8 | M8 | M8 |

| Spherical Bearing Type | - | - | - |

| Main Body Material | Stainless Steel | Chrome Molybdenum Steel | Chrome Molybdenum Steel |

| Connecting Thread Shape | Threaded | Threaded | Tapped |

| Inner Dia. d(Ø) | 8 | 8 | 8 |

| Type | Rod End Bearings | Rod End Bearings | Rod End Bearings |

| Connecting Thread Direction | Left-hand Thread | Right-hand Thread | Right-hand Thread |

| Liner Material | Resin | Resin | Resin |

| Ball Material | Stainless Steel | Stainless Steel | Stainless Steel |

| Allowable Tilt Angle α(deg) | 12 | 14 | 14 |

| Lubrication Method | Oil Free | Oil Free | Oil Free |

Loading...

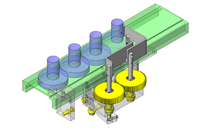

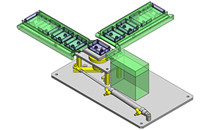

Application example related to this category

Related Categories to Rod End Bearings, Spherical Bearings

FAQ Rod End Bearings, Spherical Bearings

- Question: What is a rod end bearing?

- Answer: A rod end bearing, also known as a spherical bearing, is like the human body's ball-and-socket joint, engineered for machines. These bearings are crucial because they allow for smooth, precise, and multi-directional movements. They are used in various demanding environments such as:

- Aircraft systems (like landing gear and control linkages)

- Automotive suspensions where flexibility and durability are paramount

- Robotic arms for precise and fluid motion - Question: What are the types of rod end bearings available?

- Answer: Rod end bearings are designed in several configurations to meet specific application needs, including:

- Standard Type: Ideal for general-purpose applications, robust and versatile.

- Short Type: Best for setups where space is at a premium.

- Link Ball (L-shaped & Straight): These provide unique mounting options for more complex or unconventional applications.

When selecting a type, consider the load capacity and thread direction to ensure compatibility and functionality in your setup. - Question: What materials are used in rod end bearings?

- Answer: Choosing the right material for your rod end bearing is critical for performance and longevity:

- S45C and Chrome Molybdenum Steel: Offers strength for heavy-duty applications.

- Aluminum: Light-weight option for applications where reducing mass is crucial.

- Stainless Steel: Excellent for resisting corrosion in harsh environments, such as marine applications.

Resins and High-Strength Alloys: These can reduce noise or offer resistance to chemicals.

Selecting the appropriate material ensures the bearing can withstand the operational environment without premature failure. - Question: What are the features of lubrication-free rod end bearings?

- Answer: Lubrication-free rod end bearings are engineered to reduce maintenance without sacrificing performance. Key features include:

- Maintenance Ease: No need for regular greasing, which means less downtime and a cleaner operation.

- Self-lubricating Materials: These bearings use advanced materials designed to reduce friction and wear naturally.

- Optional Lubrication Holes: For applications where additional lubrication might be necessary, enhancing flexibility in maintenance practices.

These bearings are especially useful in hard-to-reach areas or in environments where maintaining traditional lubrication routines is challenging. - Question: How do I select the right rod end bearing for my application?

- Answer: Selecting the right rod end bearing involves understanding the specific requirements of your application. Consider the following:

- Load Capacity: Ensure the bearing can handle the operational forces.

- Thread Direction: Match the thread type (right-hand or left-hand) with your assembly requirements.

- Material Compatibility: Choose a material that suits your environmental conditions to avoid issues like corrosion.

- Maintenance Requirements: Consider how often maintenance can be performed; opt for lubrication-free models if necessary.

Utilize tools like CAD downloads for virtual testing and consult manufacturer datasheets for detailed specifications. When in doubt, reaching out to a supplier for guidance can help ensure you choose the best component for your needs.

How can we improve?

How can we improve?