(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- การยกเลิกจำหน่ายสินค้าประเภทอุปกรณ์นิวเมติกส์ (Pneumatic equipment) รุ่น “Economy Series” | Notice of End of Sales for Economy Series Pneumatic Equipment Category > คลิก

MISUMI Rollers(Roller Type:Metal Roller)

Configure

Specification/Dimensions

-

O.D.(mm)

-

Roller Type

- Urethane/Rubber Roller

- Metal Roller

- Plastic Roller

- Adjusting Components

-

Material

- Steel

- Aluminum

- Stainless Steel

- Urethane

- Plastic

-

Roller Shape

-

Straight

Straight -

Crowned

Crowned -

Groove

Groove -

Knurled

Knurled

-

-

Inner Dia. d(mm)

-

Length(mm)

- ~50

- ~100

- ~300

- ~500

- ~1000

-

Urethane Rubber Processing

|

Mounting Method

|

|

|---|---|

Brand |

|

Filter By |

|

| CAD |

|

| Days to Ship |

|

- 6 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

MISUMI

Standard expansionThe total length of the roller can now be specified in 1mm increments! Please use the L dimension specified type. FeaturesA roller with a bearing that can be selected from various metals and surface treatments. There are two types of shapes: straight type and crown type.

You can choose the material from steel (equivalent to S45C), stainless steel (SUS304), or aluminum (aluminum alloy).

For the L designation type, dimensions can be specified in 1mm increments!

In addition, the bearing can be changed to a stainless steel type with additional machining (SB). Please refer to the specification table for the range of dimensions that can be specified.From: ฿ 517.39 Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

Metal Rollers - Straight, Crowned

MISUMI

Standard expansionThe total length of the roller can now be specified in 1mm increments! Please use the L dimension specified type. FeaturesA roller with a variety of metals and surface treatments available. There are two types of shapes: straight type and crown type.

You can choose the material from steel (equivalent to S45C), stainless steel (SUS304), or aluminum (aluminum alloy).

For the L designation type, dimensions can be specified in 1mm increments!

Also, with additional machining (MC), tapped holes can be machined at two locations on the outside diameter. Please refer to the specification table for the range of dimensions that can be specified. Related products[New product] Grooved roller for round belts: Multiple grooves on one roller This makes it possible to reduce the number of parts!!From: ฿ 173.65 Days to Ship: 8 Day(s)

8 Day(s)

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025Metal Rollers - with Oil Free Bushings (Core Only)

MISUMI

Since it uses an oil-free bushing instead of a bearing, it is a space-saving metal roller with an outer diameter of φ8 or more.

Please choose the material of the roller from stainless steel (SUS304) or aluminum (aluminum alloy).

For details on the dimensions of the bush, please refer to the details of the bush in the external drawings and specification table.From: ฿ 208.69 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

MISUMI

Rollers excellent in O.D. tolerance and geometric tolerance. Please use them for conveyance requiring high accuracy.Days to Ship: 7 Day(s)

7 Day(s)

-

You can add up to 6 items per a category to the compare list.

Days to Ship: 10 Day(s)

10 Day(s)

-

You can add up to 6 items per a category to the compare list.

Metal Rollers - Female Thread Type

MISUMI

This is a metal roller with a tap. By using a tap, it can be easily attached to the shaft.

There are two types of shapes: straight or crown type. You can choose the material from stainless steel (SUS304) or aluminum (aluminum alloy).

Please refer to the specification table for the range of dimensions that can be specified.From: ฿ 251.61 Days to Ship: 5 Day(s)

5 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Mounting Method |

| O.D.(mm) |

| Roller Type |

| Material |

| Roller Shape |

| Inner Dia. d(mm) |

| Length(mm) |

| Urethane Rubber Processing |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI |

| Product Series | ||||||

| CAD |

|

|

|

|

|

|

| From | ฿ 517.39 | ฿ 173.65 | ฿ 208.69 Special Price On Sale Until 31/03/2025 | ฿ 251.61 | ||

| Days to Ship | 5 Day(s) | 8 Day(s) | Same day | 7 Day(s) | 10 Day(s) | 5 Day(s) |

| Mounting Method | With Bearings | Straight | Bushing | Straight | Straight | Set Screw |

| O.D.(mm) | 20 ~ 50 | 20 ~ 80 | 8 ~ 30 | 30 ~ 80 | 30 ~ 60 | 20 ~ 80 |

| Roller Type | Metal Roller | Metal Roller | Metal Roller | Metal Roller | Metal Roller | Metal Roller |

| Material | Steel / Aluminum / Stainless Steel | Steel / Aluminum / Stainless Steel | Aluminum / Stainless Steel | Steel / Aluminum | Aluminum | Aluminum / Stainless Steel |

| Roller Shape | Straight / Crowned | Straight / Crowned | Straight | Straight | Straight | Straight / Crowned |

| Inner Dia. d(mm) | 6 ~ 15 | 8 ~ 30 | 3 ~ 15 | 8 ~ 35 | 15 ~ 55 | 8 ~ 30 |

| Length(mm) | ~50 / ~100 | ~50 / ~100 | ~50 | ~100 / ~300 / ~500 / ~1000 | ~50 / ~100 / ~300 | ~50 / ~100 |

| Urethane Rubber Processing | - | - | - | - | - | - |

Loading...

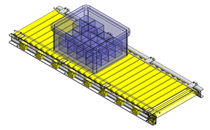

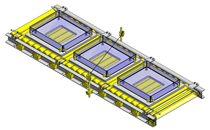

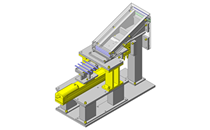

Application example related to this category

Related Categories to Rollers

FAQ Rollers

- Question: What are the different types of rollers available for industrial applications?

- Answer: There are several types of rollers, including urethane, rubber, plastic, and metal. Urethane and rubber rollers are often used for their flexibility and shock absorption. Plastic rollers are chosen for lightweight applications, and metal rollers are preferred for heavy-duty tasks where durability is crucial. Each type has various subtypes such as straight, crowned, and grooved rollers, which are selected based on specific application requirements.

- Question: How do I choose the right roller material for my application?

- Answer: The choice of roller material depends on the application’s requirements, including load capacity, environmental conditions, and desired lifespan. For example, stainless steel rollers offer high durability and resistance to corrosion, making them suitable for harsh environments. Urethane rollers provide good abrasion resistance and are ideal for applications involving delicate materials. Plastic rollers are suitable for lightweight, non-abrasive tasks and offer good chemical resistance.

- Question: What factors should I consider when selecting roller dimensions?

- Answer: Key factors include the outer diameter (O.D.), inner diameter (I.D.), and length of the roller. The outer diameter affects the roller's speed and torque capabilities, while the inner diameter must match the shaft size for proper mounting. The length should correspond to the width of the material being transported. Additionally, consider the roller's weight capacity and the space available within your machinery.

- Question: What are the benefits of using rollers with bearings?

- Answer: Rollers with bearings reduce friction, improve rolling efficiency, and extend the lifespan of both the roller and the machinery. Bearings ensure smooth and consistent movement, which is essential for high-speed applications and heavy-duty operations. They also help in reducing maintenance costs by minimizing wear and tear on the rollers.

- Question: How do different roller shapes impact their functionality?

- Answer: Roller shapes such as straight, crowned, and grooved have distinct functionalities. Straight rollers provide uniform support and are suitable for general applications. Crowned rollers help maintain the alignment of belts and prevent slippage, making them ideal for conveyor systems. Grooved rollers are used for guiding and aligning materials, such as cables or thin sheets, to ensure they remain on track during processing.

- Question: What mounting methods are available for rollers, and how do they differ?

- Answer: Rollers can be mounted using various methods, including with bearings, set screws, keyways, bushings, and shafts. Bearings provide smooth rotation, set screws allow easy adjustment and secure fitting, keyways offer precise alignment for high-torque applications, bushings provide a firm, non-rotating mount, and shafts are used for direct attachment to drive systems. The choice of mounting method depends on the specific application and operational requirements.

- Question: How does roller hardness affect its performance?

- Answer: Roller hardness, typically measured on the Shore scale, impacts the roller's grip, wear resistance, and shock absorption. Softer rollers (lower Shore hardness) provide better grip and shock absorption but may wear out faster. Harder rollers (higher Shore hardness) offer greater wear resistance and are better for high-load applications. The appropriate hardness should be selected based on the material being processed and the operating conditions.

- Question: What are the common applications for urethane and rubber rollers?

- Answer: Urethane and rubber rollers are commonly used in applications that require flexibility, impact resistance, and noise reduction. They are ideal for conveyor systems, material handling, printing, and packaging industries. Urethane rollers are particularly valued for their durability and ability to handle abrasive materials, while rubber rollers are preferred for their shock-absorbing properties and grip.

- Question: How can I determine the appropriate roller load capacity?

- Answer: To determine the appropriate roller load capacity, consider the weight of the materials to be transported, the speed of operation, and the environmental conditions. The load capacity should exceed the maximum expected weight to ensure durability and prevent premature wear. Check the manufacturer’s specifications for load ratings and factor in any additional forces that may affect the roller, such as impacts or dynamic loads.

- Question: What are the advantages of using grooved rollers in industrial settings?

- Answer: Grooved rollers provide precise guidance for materials, ensuring they stay aligned during movement. This is crucial for applications involving narrow or thin materials, such as tapes, wires, or cables. Grooved rollers help prevent lateral movement and slippage, maintaining process accuracy and reducing material wastage. They are widely used in textile, packaging, and electronic manufacturing industries where precise control of material flow is essential.

How can we improve?

How can we improve?