(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

MISUMI Keyless Bushing (Fastening Fittings)(Cleaning Method:Precision Cleaning)

Configure

Specification/Dimensions

-

Type

-

Flanged

Flanged -

Straight

Straight -

Nut Tightening

Nut Tightening -

Thin Wall

Thin Wall -

Direct Mounting

Direct Mounting -

Sleeve

Sleeve -

Hydraulic

Hydraulic

-

-

Shaft Bore Dia. d(Ø)

-

Hub Dia.(Ø)

- 8

- 9

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 47.60

- 48

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 57.13

- 59

- 60

- 60.5

- 62

- 64

- 65

- 67

- 68

- 69.83

- 70

- 71

- 72

- 73

- 75

- 77

- 78

- 79

- 80

- 82

- 83

- 84

- 85

- 85.70

- 87

- 88

- 90

- 91

- 93

- 95

- 96

- 97

- 101

- 106

- 107.93

- 110

- 114

- 115

- 120

- 124

- 125

- 130

- 134

- 135

- 145

- 155

- 165

- 180

- 225

- 260

- 285

-

Body Material

- Steel

- Stainless Steel

- Aluminum

-

Allowable Torque Range(N•m)

-

Centering

- Provided

- None

-

Surface Treatment

- None

- Black Oxide

- Electroless Nickel Plating

- Anodize

-

Tightening Structure

-

Tightening Method

-

Allowable Torque(N•m)

-

Cleaning Method

- Degreasing

- Precision Cleaning

-

Characteristics/Applications

- Clean washed

-

Environmentally friendly

- RoHS Compliant (10 Substances)

Brand |

|

|---|---|

| CAD |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack]MechaLock - Compact](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310858959/110310858959_001_20230911105917.jpg?$product_view_b$)

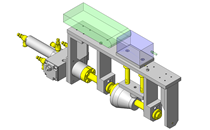

[Clean & Pack]MechaLock - Compact

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil removal General Environment Regular assembly process Post battery assembly process SH-□□ Precision Cleaning Degassing Double Packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing Double Packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.[Features]Is provided with the Centering function and is suitable for combination use with small-sized hubs.

From: ฿ 3,304.31 Days to Ship: 8 Day(s)

8 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack]MechaLock - Standard](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310859229/110310859229_001_20230911105917.jpg?$product_view_b$)

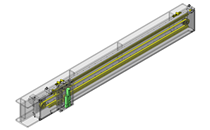

[Clean & Pack]MechaLock - Standard

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil removal General Environment Regular assembly process Post battery assembly process SH-□□ Precision Cleaning Degassing Double Packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing Double Packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.From: ฿ 3,571.29 Days to Ship: 7 Day(s)

7 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Type |

| Shaft Bore Dia. d(Ø) |

| Hub Dia.(Ø) |

| Body Material |

| Allowable Torque Range(N•m) |

| Centering |

| Surface Treatment |

| Tightening Structure |

| Tightening Method |

| Allowable Torque(N•m) |

| Cleaning Method |

| Characteristics/Applications |

| Environmentally friendly |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI |

| Product Series | ||

| CAD |

|

|

| From | ฿ 3,304.31 | ฿ 3,571.29 |

| Days to Ship | 8 Day(s) | 7 Day(s) |

| Type | Thin Wall | Flanged |

| Shaft Bore Dia. d(Ø) | 5 ~ 50 | 5 ~ 50 |

| Hub Dia.(Ø) | 12 ~ 65 | 16 ~ 72 |

| Body Material | Stainless Steel | Stainless Steel |

| Allowable Torque Range(N•m) | 2.0~20.0 ~ 500.1~700.0 | 2.0~20.0 ~ 700.1~1000.0 |

| Centering | Provided | Provided |

| Surface Treatment | None | None |

| Tightening Structure | Single Cone Type | Single Cone Type |

| Tightening Method | Mechanical Type (Wedge Type) | Mechanical Type (Wedge Type) |

| Allowable Torque(N•m) | 3 ~ 690 | 2.8 ~ 754.3 |

| Cleaning Method | Precision Cleaning | Precision Cleaning |

| Characteristics/Applications | Clean washed | Clean washed |

| Environmentally friendly | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) |

Loading...

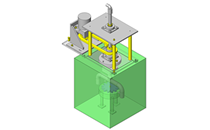

Application example related to this category

Related Categories to Keyless Bushing (Fastening Fittings)

FAQ Keyless Bushing (Fastening Fittings)

- Question: What is a Keyless Bushing and how does it work?

- Answer: A Keyless Bushing is a mechanical component used for fastening fittings, providing a secure connection between shafts and hubs without the need for traditional keys. It utilizes frictional forces to securely grip the shaft and hub, ensuring a backlash-free fit.

- Question: What are the benefits of using Keyless Bushings?

- Answer: Keyless Bushings offer several advantages, including simplified installation without the need for keyways, reduced maintenance time and costs, and enhanced reliability due to their secure locking mechanisms. They also provide precise and backlash-free shaft-to-hub connections.

- Question: How do I install a Keyless Bushing?

- Answer: Installing a Keyless Bushing is straightforward. Simply slide the bushing onto the shaft and tighten the locking screws to achieve a secure grip between the shaft and the hub. Detailed installation instructions can be found in the product manual.

- Question: Can Keyless Bushings be used in high-speed applications?

- Answer: Yes, Keyless Bushings are suitable for use in high-speed applications. They are engineered to provide secure and reliable shaft-to-hub connections even under high rotational speeds, ensuring smooth operation and minimal vibration.

- Question: What materials are Keyless Bushings made of?

- Answer: Keyless Bushings are typically made from high-quality materials such as stainless steel, carbon steel, or alloy steel. These materials offer excellent strength, durability, and corrosion resistance, ensuring long-term performance in various environments.

- Question: Are Keyless Bushings reusable?

- Answer: Yes, Keyless Bushings are reusable components. They can be easily removed from one application and installed in another, making them a cost-effective solution for multiple shaft-to-hub connections.

- Question: Do Keyless Bushings require lubrication?

- Answer: Keyless Bushings typically do not require lubrication for normal operation. However, applying a small amount of lubricant to the shaft before installation can help facilitate easier assembly and removal.

![[Clean & Pack]MechaLock - Compact](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310858959/110310858959_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]MechaLock - Standard](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310859229/110310859229_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]MechaLock - Compact](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310858959/110310858959_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]MechaLock - Standard](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310859229/110310859229_001_20230911105917.jpg?$product_view_c$)

How can we improve?

How can we improve?