(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

MISUMI Contact Probes(Barrel, Receptacle Outer Dia. D2:0.4~0.43)

Configure

Specification/Dimensions

-

Plunger Outer Dia. D1(Ø)

-

Mounting Pitch(mm)

-

Type

-

Allowable Current(A)

-

Plunger Length L1 (Range)(mm)

-

End Shape

-

Cylinder

Cylinder -

Half Cylinder

Half Cylinder -

Wire Wrap

Wire Wrap

-

-

Barrel, Receptacle Outer Dia. D2(Ø)

-

Barrel, Receptacle Length L2 (Range)(mm)

-

Integrated Probe Type

-

Plunger Surface Treatment

-

Receptacle Outermost Dia. D (Range)(Ø)

-

Properties

-

Plunger Material

- Copper Alloy

- Carbon Steel

- Others

-

Resistance(mΩ)

-

Plunger Tip Shape

-

Needle

Needle -

Triangular Pyramid

Triangular Pyramid -

Three-Needle

Three-Needle -

Sphere Shape (SR)

Sphere Shape (SR) -

Cup

Cup -

Flat

Flat -

Straight Crown

Straight Crown -

Tapered Crown

Tapered Crown -

Waffle

Waffle

-

-

Stroke (Range)(mm)

- <1

- 1~2.6

- 3~4.5

- 5~6.5

- 7~9.5

- >10

-

2/3 Stroke Spring Pressure (Range)(gf)

- 0~30

- 30.1~50

- 50.1~100

- 100.1~150

- 150.1~200

- 200.1~300

- 300.1~

-

Barrel, Receptacle Material

-

Initial Spring Pressure (Range)(gf)

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025Contact Probe / Receptacle (With Lead), 018 Series【50 Pieces Per Package】

MISUMI

Convenient and economical Bulk Package | Full Stroke 1mmFrom: ฿ 3,534.00 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025Contact Probe / Receptacle (With Lead), 030 Series【50 Pieces Per Package】

MISUMI

Convenient and economical Bulk Package | Full Stroke 1mmFrom: ฿ 2,542.00 Special Price Days to Ship: Same day

Same day

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Plunger Outer Dia. D1(Ø) |

| Mounting Pitch(mm) |

| Type |

| Allowable Current(A) |

| Plunger Length L1 (Range)(mm) |

| End Shape |

| Barrel, Receptacle Outer Dia. D2(Ø) |

| Barrel, Receptacle Length L2 (Range)(mm) |

| Integrated Probe Type |

| Plunger Surface Treatment |

| Receptacle Outermost Dia. D (Range)(Ø) |

| Properties |

| Plunger Material |

| Resistance(mΩ) |

| Plunger Tip Shape |

| Stroke (Range)(mm) |

| 2/3 Stroke Spring Pressure (Range)(gf) |

| Barrel, Receptacle Material |

| Initial Spring Pressure (Range)(gf) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI |

| Product Series | Contact Probe / Receptacle (With Lead), 018 Series【50 Pieces Per Package】 | Contact Probe / Receptacle (With Lead), 030 Series【50 Pieces Per Package】 |

| CAD |

|

|

| From | ฿ 3,534.00 Special Price On Sale Until 31/03/2025 | ฿ 2,542.00 Special Price On Sale Until 31/03/2025 |

| Days to Ship | Same day | Same day |

| Plunger Outer Dia. D1(Ø) | - | - |

| Mounting Pitch(mm) | - | - |

| Type | Receptacle | Receptacle |

| Allowable Current(A) | - | - |

| Plunger Length L1 (Range)(mm) | - | - |

| End Shape | - | - |

| Barrel, Receptacle Outer Dia. D2(Ø) | 0.4~0.43 | 0.4~0.43 |

| Barrel, Receptacle Length L2 (Range)(mm) | 10.1~15 | 10.1~15 |

| Integrated Probe Type | - | - |

| Plunger Surface Treatment | Nickel Plating Base, Gold Plating | Nickel Plating Base, Gold Plating |

| Receptacle Outermost Dia. D (Range)(Ø) | 0.01~1 | 0.01~1 |

| Properties | Standard | Standard |

| Plunger Material | - | - |

| Resistance(mΩ) | - | - |

| Plunger Tip Shape | - | - |

| Stroke (Range)(mm) | - | - |

| 2/3 Stroke Spring Pressure (Range)(gf) | - | - |

| Barrel, Receptacle Material | Copper Alloy | Copper Alloy |

| Initial Spring Pressure (Range)(gf) | - | - |

Loading...

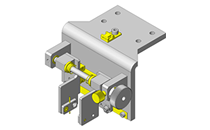

Application example related to this category

Related Categories to Contact Probes

FAQ Contact Probes

- Question: What are the applications of different types of probes?

- Answer: Touch probe heads are designed for various industrial applications, each suited to specific measurement tasks:

Single-ended probes: Typically used for basic measurements where a single point of contact is sufficient. Ideal for simple distance measurements or when space constraints limit the use of larger probes.

Double-ended probes: Offer dual functionality, allowing for contact at two points simultaneously. These are useful in applications requiring alignment or balance checks, as well as in more complex geometrical measurements.

Adjustable probes: Feature mechanisms that allow the tip's position to be finely adjusted, enhancing precision in tasks that require highly accurate placement or alignment.

High-current probes: Designed to handle higher electrical currents, these are essential in applications that involve electrical measurements or need to accommodate a higher power load. - Question: How do I select the right touch probe head?

- Answer: Selecting the right touch probe head involves a detailed understanding of your measurement needs and the specifics of your machinery. Here’s an expanded guide on how to choose the best probe:

Assess Outer Diameter (O.D.): This determines how the probe fits into your machine setup. Ensure the diameter aligns with your machine's mounting specifications.

Probe Type: Choose between single-ended for simpler tasks or double-ended for complex or dual-contact measurements. Consider adjustable or high-current probes for specialized tasks.

Electrical Specifications: Look at the electrical current and voltage ratings of the probe. It’s crucial these match your system's requirements to avoid performance issues or equipment damage.

Environment and Material Compatibility: Consider the environmental conditions (like temperature and humidity) and the material compatibility, especially if the probe is used in harsh conditions.

Accuracy Requirements: Higher precision might necessitate probes with better sensitivity or those made from materials that offer greater stability and less thermal expansion.

By closely aligning these factors with your specific needs, you ensure that the probe you select enhances the functionality and accuracy of your machinery. - Question: What are the applications of different types of probes?

- Answer: The applications of different types of probes are quite diverse, and choosing the right type depends heavily on the specific measurement tasks involved:

Single-ended probes are typically used for straightforward, one-point contact measurements. They are ideal for applications where minimal contact is needed, such as checking the presence or absence of a component or simple dimension checking.

Double-ended probes are more suitable for applications that require contact with two separate points simultaneously. This can be essential for tasks that need to measure differential distances or check the alignment between two points.

Adjustable probes provide versatility, allowing for adjustments to the probe length or angle, making them suitable for precision tasks where measurement targets vary frequently or are located in difficult-to-access areas.

High-current probes are used in applications where higher electrical throughput is necessary. They are crucial in environments where electrical measurements need to accommodate larger currents without affecting the probe's performance or safety.

Each type of probe offers unique benefits that can be matched to the specific requirements of different industrial, scientific, or quality control applications.

How can we improve?

How can we improve?