(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน มิถุนายน 2567 | Notice holiday in June 2024 > คลิก

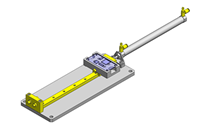

KYB Shock Absorbers, Gas Springs(Orifice Type:Dash Pot Type)

KYB offers products Shock Absorbers, Gas Springs specified by Orifice Type Dash Pot Type from Automation Components product category. There are a total of 1 items. Search and select detailed specifications of parts for your machine with free CAD downloads. KYB products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Search by specifying the lower class category

Configure

Specification/Dimensions

-

Structure

-

Nominal Mounting Screw [M]

-

Overall Length L(mm)

- 8.8

- 10

- 11

- 11.3

- 12

- 12.3

- 13

- 13.6

- 15

- 15.8

- 16

- 17

- 18

- 19

- 19.4

- 19.5

- 20

- 21

- 23

- 23.8

- 24.6

- 25

- 26

- 28

- 28.6

- 29

- 29.5

- 29.6

- 30

- 30.5

- 31

- 31.6

- 32

- 32.5

- 32.6

- 32.7

- 33

- 33.3

- 33.5

- 33.6

- 34

- 34.5

- 35

- 35.2

- 35.4

- 35.5

- 36

- 36.2

- 36.5

- 37

- 37.1

- 38

- 38.1

- 38.5

- 38.7

- 39

- 39.5

- 39.6

- 39.7

- 40

- 40.5

- 41

- 41.5

- 42

- 42.6

- 44

- 44.5

- 45

- 45.5

- 45.8

- 46

- 46.5

- 46.6

- 46.8

- 47

- 48

- 48.9

- 49

- 49.6

- 50

- 51

- 51.3

- 51.5

- 52

- 52.3

- 52.7

- 53

- 53.7

- 53.8

- 54

- 54.3

- 54.5

- 54.6

- 55

- 55.2

- 55.3

- 55.6

- 56

- 57

- 57.1

- 57.2

- 57.5

- 57.6

- 58

- 58.5

- 58.7

- 58.9

- 59

- 60

- 60.2

- 61

- 61.3

- 61.4

- 61.5

- 62

- 62.2

- 62.3

- 62.5

- 62.6

- 62.7

- 63

- 63.7

- 64

- 64.9

- 65

- 65.2

- 66

- 67

- 68

- 69

- 69.2

- 69.4

- 69.5

- 70

- 71

- 71.1

- 71.5

- 72

- 72.4

- 73

- 73.2

- 74

- 75

- 76

- 76.2

- 77

- 77.1

- 78

- 78.3

- 79

- 79.1

- 79.3

- 79.5

- 80

- 80.5

- 81

- 82

- 82.5

- 82.6

- 82.7

- 83

- 83.1

- 84

- 84.1

- 85

- 86

- 86.6

- 87

- 87.1

- 87.9

- 88

- 88.2

- 88.5

- 89.5

- 90

- 90.6

- 91

- 91.3

- 91.5

- 91.8

- 92

- 92.2

- 92.5

- 92.6

- 92.8

- 92.9

- 93

- 93.5

- 94

- 94.6

- 95

- 95.2

- 95.5

- 96

- 96.6

- 96.7

- 96.8

- 97

- 97.5

- 98

- 98.2

- 98.5

- 98.7

- 99

- 99.9

- 100

- 100.2

- 101

- 101.5

- 101.7

- 102

- 103

- 103.1

- 103.4

- 103.8

- 105

- 105.2

- 105.4

- 106

- 106.1

- 107

- 107.2

- 107.5

- 107.6

- 107.7

- 108

- 108.2

- 108.5

- 109

- 109.5

- 110

- 111

- 111.4

- 112

- 112.5

- 113.4

- 113.5

- 113.9

- 114

- 114.3

- 115

- 116

- 117

- 117.5

- 118

- 118.5

- 118.6

- 120

- 120.7

- 121

- 122

- 122.5

- 122.7

- 123

- 124

- 124.5

- 125

- 126.5

- 127

- 128

- 128.5

- 128.8

- 129

- 129.5

- 130

- 130.3

- 130.5

- 131

- 131.6

- 131.7

- 132.2

- 132.5

- 133

- 134

- 136

- 137

- 137.5

- 138

- 138.1

- 138.3

- 138.4

- 138.5

- 139

- 139.2

- 140

- 141

- 141.5

- 141.8

- 141.9

- 142

- 142.6

- 143

- 143.5

- 144

- 145

- 145.8

- 146.4

- 147

- 148.8

- 149

- 150

- 150.4

- 150.7

- 151

- 151.2

- 152

- 152.5

- 152.8

- 153

- 154

- 154.5

- 155

- 155.3

- 155.4

- 155.8

- 156

- 157.4

- 157.8

- 158

- 161.6

- 162

- 164.5

- 165

- 166

- 167

- 167.5

- 170

- 171.5

- 173

- 174

- 175.6

- 176

- 178

- 180

- 181.5

- 183

- 183.6

- 184.3

- 185

- 185.5

- 186

- 187

- 188

- 189

- 189.1

- 190

- 192

- 192.5

- 195

- 200.5

- 202

- 202.2

- 202.4

- 203.4

- 204

- 205

- 205.6

- 206.5

- 212.5

- 213

- 214

- 214.2

- 214.4

- 217

- 218

- 218.5

- 220

- 220.5

- 221.5

- 222

- 223.5

- 225

- 225.4

- 226

- 228

- 230

- 232

- 232.5

- 232.8

- 234.5

- 235

- 238

- 239

- 241

- 243

- 244.1

- 245

- 245.5

- 246

- 246.1

- 246.5

- 247

- 248

- 250

- 252

- 252.4

- 254.5

- 256.3

- 257.1

- 264

- 264.7

- 265

- 265.4

- 267

- 275

- 275.4

- 276.4

- 277.1

- 282.5

- 291.5

- 292

- 298.4

- 300

- 302.5

- 312

- 313

- 317

- 322.3

- 323

- 326

- 326.4

- 328

- 334

- 335.5

- 336.5

- 341

- 343

- 345

- 345.1

- 350

- 356.3

- 363.7

- 370.4

- 390

- 398.5

- 399

- 414

- 419

- 420.4

- 440.7

- 445

- 446

- 450

- 456

- 456.3

- 460.5

- 470.9

- 471

- 473

- 493.7

- 494

- 514

- 516

- 516.9

- 528.8

- 547.9

- 565

- 642.9

- 643

- 674.9

- 744.5

- 745

- 1037.1

- 1225.5

-

Stroke S(mm)

- 3

- 4

- 4.1

- 4.2

- 4.5

- 5

- 5.1

- 6

- 6.4

- 6.6

- 7

- 7.6

- 8

- 8.5

- 9

- 9.9

- 10

- 10.4

- 11

- 12

- 12.3

- 12.5

- 12.7

- 13

- 14

- 14.5

- 15

- 16

- 17

- 18

- 19

- 19.1

- 19.5

- 20

- 21

- 21.5

- 22

- 23

- 23.1

- 24

- 25

- 25, 50, 75

- 25.4

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 35

- 36

- 38

- 39

- 40

- 43

- 44

- 45

- 47

- 48

- 49

- 50

- 50, 100

- 50.8

- 55

- 57

- 59

- 60

- 62

- 63

- 65

- 67

- 70

- 73

- 75

- 76

- 80

- 88.9

- 90

- 97

- 100

- 101.6

- 124

- 125

- 127

- 146

- 150

- 152.4

- 165

- 165.1

- 178

- 198

- 200

- 203.2

- 250

- 254

- 304.8

-

Max. Absorbed Energy(J)

- 0.049

- 0.098

- 0.1

- 0.2

- 0.25

- 0.29

- 0.294

- 0.3

- 0.39

- 0.49

- 0.5

- 0.6

- 0.68

- 0.75

- 0.8

- 0.98

- 1

- 1,300

- 1.02

- 1.2

- 1.25

- 1.4

- 1.47

- 1.5

- 1.6

- 1.76

- 1.77

- 1.8

- 1.96

- 2

- 2,260

- 2,300

- 2.05

- 2.2

- 2.4

- 2.45

- 2.5

- 2.8

- 2.9

- 2.94

- 3

- 3.23

- 3.25

- 3.43

- 3.5

- 3.62

- 3.7

- 3.8

- 3.9

- 3.92

- 4

- 4,000

- 4,520

- 4.5

- 4.8

- 4.9

- 5

- 5,700

- 5.4

- 5.5

- 5.88

- 5.9

- 6

- 6,780

- 6.3

- 6.5

- 6.86

- 7

- 7,300

- 7.8

- 8

- 8.8

- 9

- 9.8

- 9.81

- 10

- 11

- 11.5

- 11.7

- 11.8

- 12

- 12.5

- 13

- 13.7

- 14.7

- 15

- 15.6

- 16

- 16.6

- 17.6

- 18

- 19.6

- 20

- 21

- 22

- 23

- 24

- 24.5

- 25

- 25.5

- 26

- 26.4

- 28

- 29

- 29.4

- 30

- 31

- 32

- 33

- 33.3

- 34

- 35

- 39

- 39.2

- 40

- 41

- 44.1

- 45

- 45.8

- 46.8

- 49

- 50

- 52

- 52.7

- 53.7

- 54

- 55

- 58.8

- 59

- 60

- 62

- 62.7

- 63.7

- 65

- 68

- 70

- 73

- 73,450

- 74

- 74.5

- 75

- 78.3

- 78.4

- 79

- 79.3

- 79.4

- 80

- 82

- 85

- 88.2

- 90

- 96,050

- 98

- 100

- 105

- 110

- 112

- 113

- 117

- 118

- 118,650

- 120

- 124

- 125

- 135

- 136

- 140

- 147

- 150

- 153

- 155

- 158

- 160

- 169

- 170

- 192

- 196

- 200

- 201

- 210

- 226

- 235

- 242

- 250

- 260

- 270

- 282

- 294

- 300

- 304

- 305

- 310

- 339

- 340

- 367

- 374

- 384

- 390

- 392

- 395

- 400

- 421

- 425

- 441

- 447

- 450

- 452

- 482

- 500

- 565

- 588

- 600

- 680

- 683

- 720

- 735

- 750

- 780

- 797

- 850

- 904

- 934

- 976

- 1020

- 1050

- 1130

- 1147

- 1170

- 1200

- 1207

- 1250

- 1627

- 1700

- 1762

- 1865

- 1898

- 1966

- 2014

- 2040

- 2260

- 2300

- 2373

- 2400

- 2550

- 3400

- 3600

- 3702

- 3729

- 3750

- 3800

- 4000

- 4080

- 4152

- 4244

- 4520

- 5100

- 5650

- 5700

- 5932

- 6120

- 6339

- 6780

- 7231

- 7255

- 7288

- 7300

- 7700

- 7711

- 8000

- 8326

- 8855

- 9039

- 10089

- 10847

- 11500

- 12000

- 12712

- 14462

- 15000

- 15400

- 18000

- 18078

- 19200

- 19207

- 21000

- 24000

- 25000

- 33896

- 36000

- 41000

- 92000

-

Main Body, Related Components

- Main Body

- Related Components

-

Orifice Type

-

Operating Environment

- Standard

- Coolant Resistant

- Water Solubility Resistance

- Dust Resistance

- Copper Group not Used

-

Body Material

- Stainless Steel

- Brass

- Steel

- Resin

- Aluminum

- Zinc Alloy

- Others

-

Nominal Mounting Screw [Inch]

Brand |

|

|---|---|

| CAD |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

From: ฿ 3,089.46 Days to Ship: Same day

Same day

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Structure |

| Nominal Mounting Screw [M] |

| Overall Length L(mm) |

| Stroke S(mm) |

| Max. Absorbed Energy(J) |

| Main Body, Related Components |

| Orifice Type |

| Operating Environment |

| Body Material |

| Nominal Mounting Screw [Inch] |

You can add up to 6 items per a category to the compare list. | |

| Brand | KYB |

| Product Series | |

| CAD |

|

| From | ฿ 3,089.46 |

| Days to Ship | Same day |

| Structure | Fixed Type |

| Nominal Mounting Screw [M] | 20 |

| Overall Length L(mm) | 114 |

| Stroke S(mm) | 20 |

| Max. Absorbed Energy(J) | 29 |

| Main Body, Related Components | Main Body |

| Orifice Type | Dash Pot Type |

| Operating Environment | Standard |

| Body Material | Steel |

| Nominal Mounting Screw [Inch] | - |

Loading...

Application example related to this category

Related Categories to Shock Absorbers, Gas Springs

FAQ Shock Absorbers, Gas Springs

- Question: How do shock absorbers function in industrial machinery, and what are their primary applications and benefits in maintaining equipment performance?

- Answer: Shock absorbers are mechanical devices that are designed to dampen the impact of sudden movements or vibrations in machinery. They work by absorbing the kinetic energy generated by the impact and dissipating it as heat. The primary applications of shock absorbers in industrial machinery include improving machine performance, reducing wear and tear on equipment, and preventing damage to the machinery and its components. By reducing the impact of sudden movements and vibrations, shock absorbers can help extend the lifespan of machinery and improve overall productivity.

- Question: What factors should be considered when selecting the appropriate shock absorber for a specific machine or piece of equipment?

- Answer: When selecting a shock absorber for a specific machine or piece of equipment, several factors should be considered. These include the weight and speed of the equipment, the type of impact or vibration that needs to be absorbed, the mounting position of the shock absorber, and the environment in which the equipment will be operating. It is also important to consider the lifespan and maintenance requirements of the shock absorber, as well as its cost.

- Question: What are the types of shock absorbers?

- Answer: There are several types of shock absorbers, including hydraulic shock absorbers, pneumatic shock absorbers, and spring shock absorbers. Hydraulic shock absorbers use fluid to dampen the impact, while pneumatic shock absorbers use compressed gas. Spring shock absorbers use a coiled spring to absorb the impact. Each type of shock absorber has its advantages and disadvantages, and the choice of which type to use depends on the specific application and requirements.

- Question: What is the typical lifespan of effective shock absorbers?

- Answer: The typical lifespan of effective shock absorbers depends on several factors, including the type and quality of the shock absorber, the severity, frequency of the impacts, and the operating conditions of the equipment. In general, high-quality shock absorbers can last for many years with proper maintenance and replacement when necessary. It is important to monitor the condition of shock absorbers regularly and replace them as soon as signs of wear or damage are detected to ensure optimal performance and safety of the equipment.

How can we improve?

How can we improve?