(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 28/7/2024 to 6:00 29/7/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

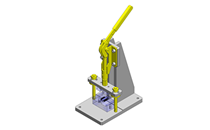

KAKUTA Push-Pull Toggle Clamps(Clamp Screw Material:Nylon)

KAKUTA offers products Push-Pull Toggle Clamps specified by Clamp Screw Material Nylon from Automation Components product category. There are a total of 2 items. Search and select detailed specifications of parts for your machine with free CAD downloads. KAKUTA products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Type

- Side Push

- Push-Pull

- Push/Pull Type

-

Tightening Force(N)

- 2,450

- 2,940

- 3,600

- 7,200

- 160

- 200

- 400

- 440

- 450

- 490

- 500

- 670

- 800

- 900

- 910

- 1150

- 1330

- 1360

- 1470

- 1500

- 1568

- 1600

- 1630

- 1670

- 1700

- 1760

- 1780

- 1800

- 1960

- 2000

- 2200

- 2250

- 2270

- 2450

- 2500

- 2670

- 2720

- 2950

- 3000

- 3110

- 3138

- 3180

- 3200

- 3340

- 3400

- 3560

- 3640

- 3740

- 3780

- 3800

- 3860

- 4000

- 4450

- 4500

- 4540

- 4900

- 5000

- 5340

- 6000

- 6700

- 6800

- 7000

- 7300

- 8900

- 9000

- 9350

- 10000

- 10680

- 11100

- 11360

- 12000

- 12460

- 16000

- 17600

- 17800

- 18000

- 18180

- 22240

- 22730

- 25000

- 26700

- 33300

- 33400

- 50000

- 71200

-

Tightening Force (Range Selectable)(N)

-

Body Material

- Steel

- Stainless Steel

- _

-

Clamp Screw Material

- Steel

- Stainless Steel

- Nylon

- Steel + Rubber Pad

-

Attaching Method

- Flange Base

- No Base

- Straight Base

- Free Mounting Direction

- Extruded Base

-

Tip Screw Type

- Bolt with Rubber

- Steel Bolt

- Stainless Steel Bolt

- Nylon Bolt

- Nuts

- Not Provided

-

Clamp Screw

- Not Provided

- Adjustable

- Stationary

-

Clamp Screw Size

Brand |

|

|---|---|

| CAD |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

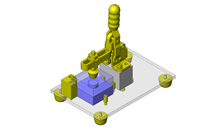

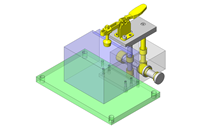

Horizontal Push-Type Clamp, No. 51BS-M

KAKUTA

Optimal for inspection, welding, assembly, and machining jigs.

[Features]

· All pressing forces are maximum values.

· Regular bolts are used to measure the pressing force.From: ฿ 1,687.24 Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

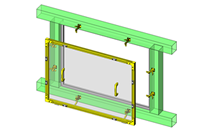

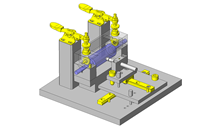

Horizontal Push-Type Clamp, No. 51B-M

KAKUTA

Optimal for inspection, welding, assembly, and machining jigs.

[Features]

· All pressing forces are maximum values.

· Regular bolts are used to measure the pressing force.From: ฿ 1,687.24 Days to Ship: 3 Day(s)

3 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Type |

| Tightening Force(N) |

| Tightening Force (Range Selectable)(N) |

| Body Material |

| Clamp Screw Material |

| Attaching Method |

| Tip Screw Type |

| Clamp Screw |

| Clamp Screw Size |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

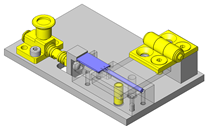

| Brand | KAKUTA | KAKUTA |

| Product Series | ||

| CAD |

|

|

| From | ฿ 1,687.24 | ฿ 1,687.24 |

| Days to Ship | 5 Day(s) | 3 Day(s) |

| Type | Side Push | Side Push |

| Tightening Force(N) | 3000 | 3000 |

| Tightening Force (Range Selectable)(N) | 2000~3099 | 2000~3099 |

| Body Material | Steel | Steel |

| Clamp Screw Material | Nylon | Nylon |

| Attaching Method | Flange Base | Flange Base |

| Tip Screw Type | Nylon Bolt | Nylon Bolt |

| Clamp Screw | Stationary | Stationary |

| Clamp Screw Size | M12 | M12 |

Loading...

Related Categories to Push-Pull Toggle Clamps

FAQ Push-Pull Toggle Clamps

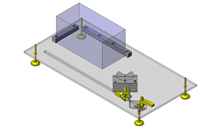

- Question: What are Push-Pull Toggle Clamps and what are they used for?

- Answer: Push-Pull Toggle Clamps are versatile clamping devices capable of exerting both push and pull forces. They are commonly used to securely hold workpieces during machining, welding, assembly, or inspection processes. Their robust design and straightforward operation make them ideal for applications requiring repetitive clamping and unclamping of parts.

- Question: How do Push-Pull Toggle Clamps work?

- Answer: Push-Pull Toggle Clamps operate using a lever mechanism that, when engaged, moves the clamping arm in a linear motion. This movement can either push or pull the workpiece against a fixed surface, depending on the clamp's configuration. The toggle mechanism locks the clamp in place, ensuring a firm grip with minimal effort.

- Question: What are the main types of Push-Pull Toggle Clamps?

- Answer: The main types of Push-Pull Toggle Clamps include horizontal push clamps, vertical push clamps, and pull clamps. Horizontal push clamps exert force sideways, vertical push clamps exert force downward, and pull clamps apply pulling force to secure the workpiece. Each type is suited for different applications based on the required direction of clamping force.

- Question: How do I select the appropriate Push-Pull Toggle Clamp for my application?

- Answer: When selecting a Push-Pull Toggle Clamp, consider factors such as the required clamping force, the direction of force (push or pull), the size and weight of the workpiece, and available mounting options. Ensure that the clamp's rated clamping force exceeds the force needed to secure your workpiece and that the clamp is compatible with the working environment and space constraints.

- Question: What are the common applications for Push-Pull Toggle Clamps?

- Answer: Common applications for Push-Pull Toggle Clamps include welding fixtures, assembly fixtures, inspection setups, and machining operations. They are essential in situations requiring repetitive clamping and releasing of workpieces due to their consistent clamping force and ease of use. They are also used in woodworking and metalworking to hold components during cutting or drilling.

- Question: What materials are Push-Pull Toggle Clamps made from?

- Answer: Push-Pull Toggle Clamps are typically made from materials such as steel, stainless steel, and cast iron. Steel and cast iron clamps are known for their strength and durability, while stainless steel clamps offer better corrosion resistance and are suitable for harsh environments or applications where hygiene is critical, such as food processing or medical device manufacturing.

- Question: How do I install a Push-Pull Toggle Clamp?

- Answer: Installing a Push-Pull Toggle Clamp involves mounting it to a work surface using screws or bolts. Ensure the clamp is positioned correctly to apply force in the desired direction. The clamp base should be securely attached to the surface to prevent movement during use. Adjust the clamping arm and handle to ensure smooth and effective operation, and test the clamp to confirm it holds the workpiece securely.

- Question: What is the maximum clamping force of Push-Pull Toggle Clamps?

- Answer: The maximum clamping force of Push-Pull Toggle Clamps varies depending on the model and size. Some clamps can exert as little as 450 N (Newtons) for light-duty tasks, while heavy-duty models can exceed 10,000 N, providing significant clamping force for large or heavy workpieces. Always select a clamp with a maximum force that meets or exceeds your specific application's requirements.

- Question: How do I maintain Push-Pull Toggle Clamps?

- Answer: Maintaining Push-Pull Toggle Clamps involves regular cleaning and lubrication to ensure smooth operation. Check for signs of wear or damage, such as bent handles or worn pivot points, and replace any damaged parts. Ensure all moving parts are free from debris and the clamping surfaces are clean and rust-free. Lubricate joints and moving components as per the manufacturer's recommendations to prevent friction and wear.

- Question: What safety precautions should I take when using Push-Pull Toggle Clamps?

- Answer: Safety precautions for using Push-Pull Toggle Clamps include ensuring the clamp is securely attached to the work surface and suitable for the clamping task. Do not exceed the recommended clamping force, as this can damage the clamp or workpiece. Wear protective gear, such as gloves and safety glasses, to prevent injuries, and ensure the clamp handle is properly aligned to avoid accidental release.

- Question: What are the advantages of using Toggle Clamps over other types of clamps?

- Answer: Toggle Clamps offer several advantages over other types of clamps, including ease and speed of use, consistent clamping force, and the ability to lock securely in place. They are particularly useful for repetitive tasks that require frequent clamping and unclamping. Toggle Clamps also provide high clamping force relative to their size, making them ideal for securely holding workpieces during machining or assembly.

- Question: Can Push-Pull Toggle Clamps be used in automated systems?

- Answer: Yes, Push-Pull Toggle Clamps can be integrated into automated systems for tasks such as robotic welding or automated assembly lines. Their reliable and easy-to-use clamping action makes them suitable for applications requiring consistent and repeatable clamping. Automation can control the clamps using pneumatic or hydraulic actuators, allowing precise control over clamping force and duration.

- Question: Are there any limitations to using Push-Pull Toggle Clamps?

- Answer: While Push-Pull Toggle Clamps are versatile and effective for many applications, they may not be suitable for very large or irregularly shaped workpieces that require custom clamping solutions. Additionally, their clamping force is limited by the clamp's design and size, so for extremely high-force applications, other clamping methods such as hydraulic clamps might be more appropriate.

- Question: What is the difference between horizontal push clamps and vertical push clamps?

- Answer: Horizontal push clamps exert force sideways, making them ideal for applications where space above the workpiece is limited. In contrast, vertical push clamps exert downward force, suitable for situations with ample vertical space where the workpiece needs to be pressed flat against a surface. The choice between horizontal and vertical clamps depends on the specific clamping requirements of the task.

- Question: How can I adjust the clamping force on a Push-Pull Toggle Clamp?

- Answer: You can adjust the clamping force on a Push-Pull Toggle Clamp by changing the position of the adjustment screws or bolts. Some clamps have adjustable screws that allow you to increase or decrease the tension applied to the workpiece. Ensure adjustments are made gradually and that the clamp remains secure without damaging the workpiece. Refer to the manufacturer's instructions for specific adjustment procedures for your clamp model.

How can we improve?

How can we improve?