(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน พฤษภาคม 2567 | Notice holiday in May 2024 > คลิก

INA Linear Bushings(Motion:Linear)

INA offers products Linear Bushings specified by Motion Linear from Automation Components product category. There are a total of 1 items. Search and select detailed specifications of parts for your machine with free CAD downloads. INA products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Inscribed Circle Dia. dr(Ø)

-

Overall Length L(mm)

- 10

- 12

- 13

- 15

- 16

- 17

- 18

- 19

- 19.050 (3/4")

- 20

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 41.275 (1-5/8")

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 57.150 (2-1/4")

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 64.5

- 65

- 66

- 67

- 67.3

- 67.5

- 68

- 69

- 70

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 88

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 102

- 102.3

- 102.5

- 103

- 105

- 106

- 108

- 109

- 110

- 111

- 112

- 114

- 115

- 118

- 120

- 121

- 122

- 123

- 124

- 125

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 138

- 140

- 141

- 142

- 144

- 145

- 148

- 150

- 151

- 153

- 154

- 155

- 155.5

- 156

- 158

- 160

- 165

- 167

- 170

- 175

- 176

- 177

- 178

- 180

- 182

- 184

- 185

- 187

- 190

- 192

- 193

- 199

- 200

- 202

- 209

- 211

- 215

- 220

- 224

- 230

- 240

- 243

- 244

- 250

- 300

- 310

-

Flange Type

-

Standard Flange

Standard Flange -

Center Flanged

Center Flanged -

Pilot Flanged

Pilot Flanged

-

-

Style

-

Standard

Standard -

Open Type, Clearance Adjusting Type

Open Type, Clearance Adjusting Type

-

-

Outer Cylinder Material

- Steel

- Stainless Steel

- Aluminum

-

Outer Cylinder Surface Treatment

- No Surface Treatment

- Surface Treatment

-

Outer Dia. D(Ø)

-

Lubrication Type

- Not Provided

- Grease coating

- With Lubrication Unit MX

-

Accuracy

-

Ball Recirculating Type

-

Motion

-

Types

-

Length

-

Eccentricity(µm)

-

Flange Shape

-

Round Flange

-

Square Flange

-

Compact Flange

-

Round Flange

-

Linear Motion / Rotational Motion

-

Linear Bushing (Linear Motion Only)

-

Linear Bushing (Linear Motion Only)

-

Basic Rated Load, Dynamic Rating

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

INA

[Features]

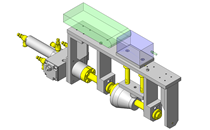

● Unlimited linear action due to ball circulation.

● As well as allowing the balls to circulate, the slot of the outer ring functions as a lubrication.

● DIN standard part.

● Precision slide parts such as in precision equipment.From: ฿ 427.46 Days to Ship: Same day

Same day

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Type |

| Inscribed Circle Dia. dr(Ø) |

| Overall Length L(mm) |

| Flange Type |

| Style |

| Outer Cylinder Material |

| Outer Cylinder Surface Treatment |

| Outer Dia. D(Ø) |

| Lubrication Type |

| Accuracy |

| Ball Recirculating Type |

| Motion |

| Types |

| Length |

| Eccentricity(µm) |

| Flange Shape |

| Linear Motion / Rotational Motion |

| Basic Rated Load, Dynamic Rating |

You can add up to 6 items per a category to the compare list. | |

| Brand | INA |

| Product Series | |

| From | ฿ 427.46 |

| Days to Ship | Same day |

| Type | Straight |

| Inscribed Circle Dia. dr(Ø) | 8 ~ 20 |

| Overall Length L(mm) | 24 ~ 30 |

| Flange Type | - |

| Style | - |

| Outer Cylinder Material | Steel |

| Outer Cylinder Surface Treatment | No Surface Treatment |

| Outer Dia. D(Ø) | 15 ~ 28 |

| Lubrication Type | Grease coating |

| Accuracy | Standard Grade |

| Ball Recirculating Type | Single |

| Motion | Linear |

| Types | Standard |

| Length | Standard |

| Eccentricity(µm) | - |

| Flange Shape | - |

| Linear Motion / Rotational Motion | - |

| Basic Rated Load, Dynamic Rating | - |

Loading...

Related Categories to Linear Bushings

FAQ Linear bushing

-

- Question: Which maker is the manufacturer of MISUMI Linear bushing?

- Answer: SURUGA Production Platform. Well-known product is XY Stage.

- Question: What is Linear bushing MX product?

- Answer: It is a product with lubrication unit MX.

Linear bushing with lubrication unit MX can realize the long term maintenance free, cost reduction and environment friendly, as well as reduce manufacturing steps because this product has already filled with grease. Please search on the keyword “Linear bushing with lubrication unit MX” for more details.

The following are some samples for this product:

Linear Bushings with Lubrication Unit MX - Single / Double / Flanged Single

Housing Units with Lubrication Unit MX - Wide Blocks - Question: Do I need to maintenance such as lubricating?

- Answer: Yes, no maintenance may shorten the service lifetime.

Maintenance methods: Apply grease at the inner side of Linear bushing before initial usage. Apply grease at the ball inside, then periodically apply every 6 months (※)

※In case of long moving distance, grease should be applied every 3 months, or every 1,000km if moving distance is over 1,000km. - Question: Is grease applied at the time of delivery?

- Answer: Except MX Lubrication Unit type, grease are not applied at the time of delivery.

MISUMI Linear Bushings are applied with Anti-rust Oil before shipment. Therefore, after de-greasing and drying, we recommend to apply grease before usage. - Question: Are grease available in your store?

- Answer: Yes.

Grease applied service also available with 3 types of grease as shown below:

• Standard grease (L type)

• Low dust generation grease (G type)

• Food grade grease (H type) - Question: Do you have any recommended grease?

- Answer: Lithium soap-based grease is recommended.

- Question: What is Food grade grease (H type)?

- Answer: It is the grease that suitable for lubrication in food, beverage, pharmaceutical processing, packing equipment, etc., and is H-1 certified by NSF.

- Question: Do you have any recommended specification for shaft?

- Answer: Yes.

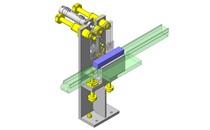

We recommend to use in combination with a hardening shaft with g6 tolerance. - Question: Please explain how to calculate the service life time.

- Answer: Please see more details at “service life time calculation” in Linear bushing general information.

- Question: Between SUS440C equivalent and SUJ2 with electroless nickel plating material, which material is better for rust-preventive?

- Answer: SUJ2 with electroless nickel plating material.

Please see more details at Salt water spray test report. - Question: Between shaft and Linear bushing, which one will worn-out faster?

- Answer: In generally, Linear bushing will be worn out faster.

This is because Linear bushing contact to ball more frequently than shaft. - Question: What are the different types of linear bushings available?

- Answer: Linear bushings are used in various applications to provide smooth and precise linear motion. There are different types of linear bushings available, For examples:

1. Standard Linear Bushings: This linear bushings are common use in general-purpose in linear motion applications.

2. Closed Linear Bushings: These linear bushings have a sealed design for protection against contaminants.

3. Open Linear Bushings: These linear bushings do not have seals, suitable for easy maintenance and accessibility.

4. Adjustable Linear Bushings: These linear bushings allow for adjustable clearance or pre-load for fine-tuning.

5. Flanged Linear Bushings: Extended flange for added support and stability.

6.Self-Lubricating Linear Bushings: Require no external lubrication, maintenance-free operation. - Question: How does a linear bearing differ from a linear bushing?

- Answer: There are some examples of differences between Linear bearings and Linear bushings

1.Load Capacity

Linear bearings are often designed to handle higher loads compared to linear bushings. The presence of rolling elements in linear bearings distributes the load over a larger contact area, allowing them to support heavier loads.

2.Construction

-Linear bearings typically have a more complex construction, involving a carriage or housing and rolling elements like balls or rollers for example linear guide’s slide block

-Linear bushings have a simpler design, usually consisting of a cylindrical sleeve or some type of linear bushings have balls inside

3.Precision:

- Linear bearings are known for their high precision and accuracy, making them suitable for applications that require precise positioning and minimal play or backlash.

- Linear bushings can provide linear motion support but may have slightly lower precision compared to linear bearings.

4.Cost

- Linear bearings with their rolling elements and higher precision tend to be more expensive.

- Linear bushings are generally more cost-effective than linear bearings. - Question: What are the applications of linear bushings?

- Answer: Linear bushings have applications in various engineering fields, including:

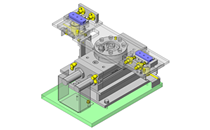

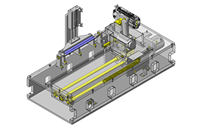

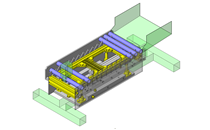

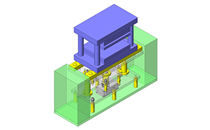

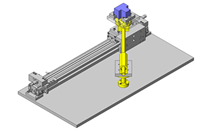

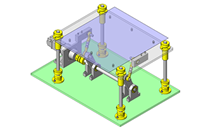

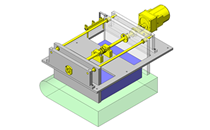

- CNC machines : To guide the movement of axes such as the X, Y, and Z axes.

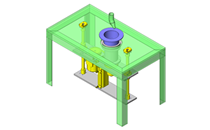

- Robotics for guiding robot arms and grippers.

- Industrial automation for assembly lines and material handling systems.

- 3D printers for accurate print head and build platform motion.

- Medical devices for controlled linear movement in surgical robots.

- Industrial machinery such as textile machines and printing presses. - Question: What factors should be considered when selecting a linear bushing?

- Answer: When selecting a linear bushing, several factors should be considered:

1. Load Capacity: Determine the maximum load the linear bushing will be subjected to. This includes both static and dynamic loads.

2. Accuracy Requirements: Consider the precision and accuracy needed for your application. Some linear bushings offer higher levels of precision, while others are more suitable for general-purpose applications.

3. Travel Speed: Evaluate the required speed of the linear motion. Higher speeds may require bushings with lower friction coefficients and smoother surfaces to minimize heat generation and wear.

4. Environmental Conditions: Take into account the operating environment such as temperature, humidity, dust, chemicals, and exposure to water or other fluids can affect the performance and durability of the bushing.

5. Mounting and Installation: Consider the ease of installation and compatibility with the mounting arrangement. Ensure that the selected bushing can be easily integrated into your system.

6. Maintenance and Lubrication: Determine the maintenance requirements and the availability of lubrication. Some linear bushings require periodic lubrication, while others are self-lubricating or maintenance-free.

-

- Question: Do all of MISUMI Linear bushing compliance with RoHS?

- Answer: Yes. Please see more details in product page.

-

- Question: Is it applicable with rotary motion?

- Answer: No.

The structure of Linear bushing is designed for linear motion. It may be damaged if used in rotary motion. - Question: Can shaft be used by repeating of insertion and removal?

- Answer: It is not suitable for repeated insertion and removal because balls may fall off or the retainer may be deformed.

Please align the core and gently install. - Question: Is it possible to use MISUMI Linear bushing in combination with other manufacturer’s shaft?

- Answer: Actually it is applicable, but we do not recommend.

MISUMI’s shafts are manufactured with extremely high accuracy, meanwhiles other manufacturers’ shafts may have variation on dimensional tolerances, dimensional accuracy, surface roughness, hardness level, etc.

How can we improve?

How can we improve?