(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

HALDER Indexing Plungers(Body Material:Zinc Diecast)

HALDER offers products Indexing Plungers specified by Body Material Zinc Diecast from Automation Components product category. There are a total of 1 items. Search and select detailed specifications of parts for your machine with free CAD downloads. HALDER products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Outer Dia. M(mm)

-

Tip Outer Dia. d(Ø)

-

Stroke S(mm)

-

Locking Mechanism

-

Mounting Method

- Screw-In

- Press Fit

- Plate Mounting

- Bolt Mounting

- Others

- Flange

-

Body Material

- Steel

- Stainless Steel

- Zinc Diecast

- Polyamide

- Others

-

Length L(mm)

-

Overall Length

- Standard

- Short

-

Tip Material

- Steel

- Stainless Steel

- S45C

-

All Stainless

- Applicable

- Not Compliant

-

Tip Surface Treatment

-

Tip Heat Treatment

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

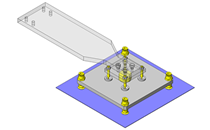

Mounting Blocks For Index Plungers And Bolts, Die-Cast

HALDER

[Features]

· Can be used for mounting index bolts and for expanding applications.

· Can also be used for mounting locating bushing EH22120.

· Operating temperature range: maximum 100°C.From: ฿ 417.00 Days to Ship: Same day

Same day

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Type |

| Outer Dia. M(mm) |

| Tip Outer Dia. d(Ø) |

| Stroke S(mm) |

| Locking Mechanism |

| Mounting Method |

| Body Material |

| Length L(mm) |

| Overall Length |

| Tip Material |

| All Stainless |

| Tip Surface Treatment |

| Tip Heat Treatment |

You can add up to 6 items per a category to the compare list. | |

| Brand | HALDER |

| Product Series | |

| From | ฿ 417.00 |

| Days to Ship | Same day |

| Type | Related Components |

| Outer Dia. M(mm) | - |

| Tip Outer Dia. d(Ø) | - |

| Stroke S(mm) | - |

| Locking Mechanism | - |

| Mounting Method | Bolt Mounting |

| Body Material | Zinc Diecast |

| Length L(mm) | - |

| Overall Length | - |

| Tip Material | - |

| All Stainless | - |

| Tip Surface Treatment | - |

| Tip Heat Treatment | - |

Loading...

Related Categories to Indexing Plungers

FAQ Indexing Plungers

- Question: What are indexing plungers?

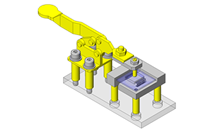

- Answer: Indexing plungers are mechanical components used to position, lock, and index parts in various applications such as machinery, jigs, and fixtures. They consist of a plunger body, a spring, and a retractable pin. The pin is engaged or disengaged by pulling or pushing a knob or lever, allowing for precise alignment and secure locking of components.

- Question: How do I choose the right indexing plunger for my application?

- Answer: To select the appropriate indexing plunger, consider the following factors:

Type of Actuation: Choose between knob, lever, or ring actuation based on your application requirements.

Material: Select materials like steel, stainless steel, or plastic depending on the environment. Stainless steel is ideal for corrosion-resistant applications.

Locking Mechanism: Some plungers come with a locking feature to hold the pin in a retracted position, useful for repetitive operations.

Thread Type and Size: Ensure the thread size and type (coarse or fine) match your mounting requirements.

Stroke Length and Pin Diameter: Choose a pin diameter and stroke length that align with the required precision and range of movement. - Question: What are the different types of indexing plungers available?

- Answer: Indexing plungers come in various types, including:

Standard Indexing Plungers: Basic plungers with or without a knob, available in different materials.

Locking Indexing Plungers: Feature a mechanism to lock the pin in a retracted position.

Precision Indexing Plungers: Designed for high repeatability and accuracy with ground pins and bushings.

Cam Action Indexing Plungers: Use a cam mechanism for engaging and disengaging the pin, suitable for applications requiring quick changes. - Question: How do indexing plungers enhance the functionality of my equipment?

- Answer: Indexing plungers provide precise positioning and secure locking, essential for repeatable operations in machinery and fixtures. They improve the accuracy of setups, reduce the time needed for adjustments, and enhance the overall efficiency of the equipment.

- Question: What maintenance is required for indexing plungers?

- Answer: Regular maintenance of indexing plungers includes:

Cleaning: Keep the plunger and its components free from debris and dust.

Lubrication: Apply appropriate lubricants to the moving parts to ensure smooth operation.

Inspection: Regularly inspect for wear and tear, especially in high-use applications, and replace any worn components to maintain precision and reliability. - Question: What are common applications of indexing plungers?

- Answer: Indexing plungers are used in various applications, including:

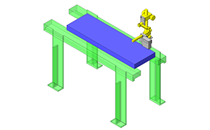

Machinery: For positioning and locking moving parts.

Jigs and Fixtures: To ensure repeatable and precise positioning in manufacturing processes.

Automation Systems: For controlling the movement and positioning of automated equipment.

Medical Devices: In equipment where precise positioning and locking are critical. - Question: How can I ensure the longevity and reliability of indexing plungers in my setup?

- Answer: To ensure longevity and reliability:

Select the right material: Use corrosion-resistant materials like stainless steel in harsh environments.

Regular Maintenance: Perform routine cleaning and lubrication.

Correct Installation: Ensure proper installation and alignment during setup to prevent undue stress on the components.

How can we improve?

How can we improve?