(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

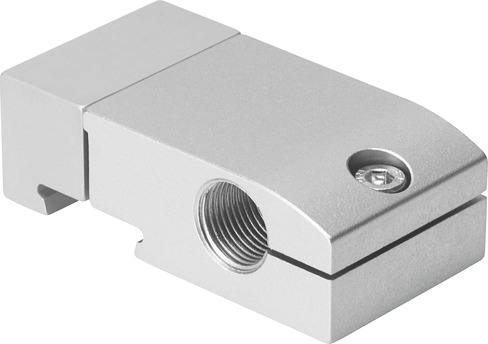

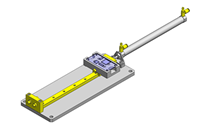

FESTO Fixed Type

Configure

Specification/Dimensions

-

Structure

-

Nominal Mounting Screw [M]

-

Overall Length L(mm)

- 15

- 16

- 18

- 19

- 21

- 25

- 26

- 28

- 28.6

- 29

- 29.5

- 29.6

- 30

- 30.5

- 31

- 32

- 32.5

- 32.6

- 32.7

- 33

- 33.3

- 33.5

- 33.6

- 34.5

- 35.4

- 35.5

- 36

- 36.5

- 37

- 37.1

- 38

- 38.5

- 38.7

- 39

- 39.5

- 40.5

- 41

- 42

- 42.6

- 44

- 44.5

- 45

- 45.5

- 45.8

- 46

- 46.6

- 46.8

- 47

- 48

- 49

- 50

- 51

- 51.3

- 51.5

- 52

- 52.3

- 52.7

- 53

- 53.7

- 54

- 54.3

- 54.5

- 55

- 55.2

- 55.3

- 56

- 57

- 57.5

- 57.6

- 58

- 58.5

- 59

- 60

- 60.2

- 61

- 61.3

- 61.5

- 62

- 62.2

- 62.3

- 62.5

- 62.6

- 62.7

- 63

- 63.7

- 64

- 65

- 66

- 67

- 68

- 69

- 69.2

- 69.4

- 69.5

- 70

- 71

- 71.1

- 71.5

- 72

- 72.4

- 73

- 74

- 75

- 76

- 77

- 77.1

- 78

- 78.3

- 79

- 79.1

- 79.3

- 79.5

- 80

- 82

- 82.7

- 83

- 83.1

- 84

- 84.1

- 85

- 86

- 86.6

- 87.9

- 88

- 88.2

- 88.5

- 90

- 90.6

- 91

- 91.5

- 91.8

- 92

- 92.2

- 92.6

- 92.8

- 93

- 95

- 96

- 96.7

- 96.8

- 97

- 97.5

- 98

- 98.5

- 99.9

- 100

- 100.2

- 101

- 101.5

- 101.7

- 103

- 103.1

- 103.4

- 103.8

- 105.2

- 106

- 106.1

- 107

- 107.2

- 108

- 108.5

- 109

- 109.5

- 110

- 111

- 112

- 112.5

- 114

- 114.3

- 115

- 117

- 117.5

- 118

- 118.5

- 122

- 123

- 124

- 124.5

- 125

- 126.5

- 127

- 128.5

- 128.8

- 129

- 129.5

- 130

- 130.3

- 132.5

- 134

- 136

- 137

- 137.5

- 140

- 141

- 141.5

- 141.8

- 141.9

- 142

- 142.6

- 143

- 144

- 145

- 145.8

- 146.4

- 147

- 149

- 150

- 150.7

- 151

- 152.5

- 153

- 154

- 154.5

- 155

- 155.8

- 156

- 158

- 166

- 167.5

- 170

- 171.5

- 173

- 176

- 183

- 185.5

- 186

- 187

- 189.1

- 190

- 192

- 192.5

- 195

- 202

- 204

- 205

- 214

- 214.2

- 217

- 218

- 218.5

- 220

- 220.5

- 223.5

- 225

- 226

- 228

- 230

- 232

- 232.8

- 234.5

- 238

- 239

- 241

- 243

- 246

- 247

- 248

- 252

- 264.7

- 275

- 282.5

- 291.5

- 300

- 317

- 326

- 326.4

- 328

- 335.5

- 336.5

- 390

- 445

- 450

- 456

- 460.5

- 565

-

Stroke S(mm)

-

Max. Absorbed Energy(J)

- 0.1

- 0.2

- 0.29

- 0.3

- 0.39

- 0.49

- 0.5

- 0.6

- 0.68

- 0.75

- 0.8

- 0.98

- 1

- 1.2

- 1.25

- 1.47

- 1.5

- 1.6

- 1.8

- 1.96

- 2

- 2.05

- 2.2

- 2.4

- 2.45

- 2.5

- 2.8

- 2.9

- 2.94

- 3

- 3.23

- 3.25

- 3.5

- 3.7

- 3.9

- 3.92

- 4

- 4.9

- 5

- 5.88

- 5.9

- 6

- 6.5

- 6.86

- 7

- 8

- 8.8

- 9

- 9.8

- 10

- 11

- 11.5

- 11.8

- 12

- 12.5

- 13.7

- 14.7

- 15

- 18

- 19.6

- 20

- 23

- 24

- 25

- 26

- 28

- 29

- 29.4

- 30

- 33

- 33.3

- 34

- 39.2

- 40

- 41

- 44.1

- 45

- 45.8

- 46.8

- 49

- 50

- 52

- 52.7

- 53.7

- 54

- 55

- 58.8

- 59

- 60

- 62

- 62.7

- 65

- 68

- 70

- 73

- 75

- 78.3

- 79

- 79.3

- 80

- 88.2

- 90

- 98

- 100

- 105

- 110

- 112

- 113

- 117

- 120

- 124

- 135

- 136

- 140

- 147

- 150

- 158

- 170

- 192

- 196

- 200

- 201

- 226

- 242

- 250

- 270

- 282

- 300

- 304

- 339

- 340

- 367

- 374

- 392

- 395

- 400

- 421

- 447

- 452

- 482

- 500

- 565

- 600

- 680

- 683

- 735

- 797

- 904

- 934

- 976

- 1020

- 1050

- 1130

- 1147

- 1207

- 1627

- 1700

- 1865

- 1898

- 1966

- 2014

- 3400

- 3702

- 3729

- 4244

- 5100

- 5650

- 6339

- 7255

- 7288

- 8000

- 8326

- 8855

- 10089

- 12000

- 12712

- 15000

- 18000

- 21000

- 25000

- 41000

- 92000

-

Main Body, Related Components

- Main Body

-

Orifice Type

-

Operating Environment

- Standard

- Coolant Resistant

- Copper Group not Used

-

Body Material

-

Nominal Mounting Screw [Inch]

Brand |

|

|---|---|

| CAD |

|

- 8 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

FESTO

[Specifications]

• Adjustable or self-adjusting

• With linear or progressive characteristic

• Stop elements: combination of cushioning and end-position sensingFrom: ฿ 3,807.31 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

FESTO

[Features]

• Shock absorbers at both ends, self-adjusting,

with end-position adjustment

[Features]

• Only possible from a stroke of 30 mm

• Set minimum stroke ≥ 2x stroke lengthFrom: ฿ 2,359.10 Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

FESTO

[Specifications]

• Cushioning with self-adjusting, progressive hydraulic shock absorber (YSRW)

• Slowly increasing cushioning force curve

• Adjustable cushioning stroke

• End-position sensing with proximity sensors SME/SMT-8

• Precision end-position adjustment

• Stop elements YSRWJ can be used for a wide variety of applications in handling and assembly technology.From: ฿ 3,864.45 Days to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

FESTO

[Specifications]

Elastic cushioning at both ends, self-adjusting, with end-position adjustmentFrom: ฿ 645.09 Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

From: ฿ 3,554.15 Days to Ship: 30 Day(s)

30 Day(s)

-

You can add up to 6 items per a category to the compare list.

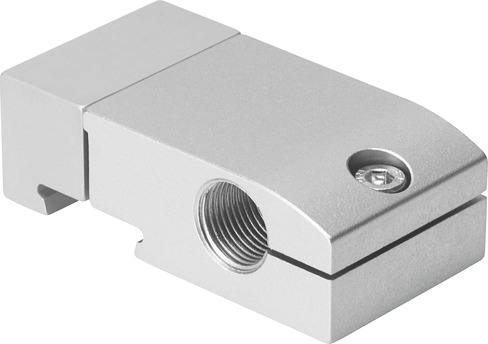

FESTO

- Shock absorber DYSW series from FESTO.

- Hydraulic shock absorber with path-controlled flow control function.

- Slowly increasing cushioning force curve.

- Long cushioning stroke (6, 8, 10, 14, 17, 20 mm).

- Suitable for low-vibration operation.

- Short cycle times possible.

- Maintenance-free.

- Metal end position on the housing.

- Continuous mounting thread with internal hex.

- Operating Environment Temperature: -10 to 80℃

- Impact velocity (m/s): 0.1 to 3

- To increase the service life: Prevent dirt or liquids getting into the inner chamber of the piston via the piston rod (e.g., by using a cover).From: ฿ 3,710.58 Days to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

From: ฿ 156.23 Days to Ship: 31 Day(s)

31 Day(s)

-

You can add up to 6 items per a category to the compare list.

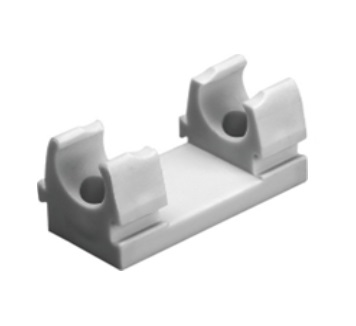

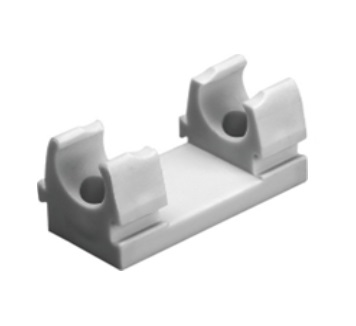

Shock Absorber Retainer, DADP-DGC Series

FESTO

[Intended use]

The shock absorber retainer fastens shock absorbers YSR(W)-DGC to the slide of linear drives DGC-...-GF/-KF/-FA or DGCI. Use the shock absorber retainer only in combination with a counter part for the cushioning:

– Stop KYC

– Intermediate-position module DADM-DGCFrom: ฿ 1,223.89 Days to Ship: 31 Day(s)

31 Day(s)

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Structure |

| Nominal Mounting Screw [M] |

| Overall Length L(mm) |

| Stroke S(mm) |

| Max. Absorbed Energy(J) |

| Main Body, Related Components |

| Orifice Type |

| Operating Environment |

| Body Material |

| Nominal Mounting Screw [Inch] |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | FESTO | FESTO | FESTO | FESTO | FESTO | FESTO | FESTO | FESTO |

| Product Series | ||||||||

| From | ฿ 3,807.31 | ฿ 2,359.10 | ฿ 3,864.45 | ฿ 645.09 | ฿ 3,554.15 | ฿ 3,710.58 | ฿ 156.23 | ฿ 1,223.89 |

| Days to Ship | Same day | 5 Day(s) | 4 Day(s) | 5 Day(s) | 30 Day(s) | 4 Day(s) | 31 Day(s) | 31 Day(s) |

| Structure | - | - | - | - | - | - | - | - |

| Nominal Mounting Screw [M] | - | - | - | - | - | - | - | - |

| Overall Length L(mm) | - | - | - | - | - | - | - | - |

| Stroke S(mm) | - | 4 ~ 10 | - | - | - | - | - | - |

| Max. Absorbed Energy(J) | 8000 ~ 92000 | 270 ~ 25000 | 21000 ~ 41000 | - | - | 15000 | - | - |

| Main Body, Related Components | - | - | - | - | - | - | - | - |

| Orifice Type | - | - | - | - | - | - | - | - |

| Operating Environment | - | - | - | - | - | - | - | - |

| Body Material | Steel | Steel | Steel | Steel | Aluminum | Steel | - | - |

| Nominal Mounting Screw [Inch] | - | - | - | - | - | - | - | - |

Loading...

Application example related to this category

Related Categories to Fixed Type

FAQ Fixed Type

- Question: What are shock absorbers used for in industrial applications?

- Answer: Shock absorbers are used to absorb and dissipate kinetic energy from impacts or vibrations, thereby reducing the impact force and stabilizing equipment. They are essential for protecting machinery and components from damage, minimizing noise, and enhancing the overall operational stability and lifespan of industrial systems.

- Question: How do fixed-type shock absorbers work?

- Answer: Fixed-type shock absorbers are designed to provide a consistent damping force. They use hydraulic or gas mechanisms to absorb energy when the piston compresses the fluid inside the absorber. The energy is then converted into heat and dissipated, effectively cushioning the impact and reducing oscillations. Fixed types are preset and do not allow for external adjustments.

- Question: What are the main types of fixed shock absorbers available?

- Answer: The main types include hydraulic shock absorbers, which use oil to absorb energy; gas shock absorbers, which use compressed gas; and elastomeric shock absorbers, which use rubber or synthetic materials. Each type is suited for specific applications based on factors like load, speed, and environmental conditions.

- Question: What should I consider when selecting a shock absorber for my equipment?

- Answer: Key considerations include the maximum load, impact velocity, and the environment where the shock absorber will be used. You should also consider the mounting configuration, the desired stroke length, and whether the shock absorber needs to handle specific conditions such as exposure to chemicals or extreme temperatures.

- Question: How can I determine the appropriate shock absorber for my application?

- Answer: Determine the maximum energy absorption required by calculating the kinetic energy of the moving parts. Check the stroke length and ensure it matches the requirements of your application. It’s also crucial to select a model with an appropriate mounting style and compatibility with the environmental conditions of your machinery.

- Question: What are the advantages of using fixed-type shock absorbers?

- Answer: Fixed-type shock absorbers offer reliable performance without the need for adjustments. They are typically more robust and have fewer moving parts than adjustable types, making them ideal for applications where consistent damping is required. They are also generally easier to install and maintain, providing cost-effective and durable solutions.

- Question: How do I install a fixed-type shock absorber?

- Answer: Installation involves securing the shock absorber to the equipment using mounting bolts or brackets. Ensure that the alignment is correct to avoid any off-axis loads that could affect performance. Refer to the manufacturer’s guidelines for specific installation instructions, including torque settings for bolts and any necessary pre-installation checks.

- Question: What materials are typically used in fixed shock absorbers?

- Answer: Common materials include steel and stainless steel for high-strength components, and aluminum for lightweight applications. The internal components are often made of durable elastomers or synthetic materials, and high-performance models may include features like corrosion-resistant coatings or specialized seals for harsh environments.

- Question: Can fixed-type shock absorbers be used in extreme temperatures?

- Answer: Yes, many fixed-type shock absorbers are designed to operate in a wide range of temperatures. Some models are built with special seals and fluids that allow them to function in both very high and very low temperatures, ensuring reliable performance in diverse industrial settings. Always check the specifications to confirm the temperature range.

- Question: How do I maintain a fixed shock absorber?

- Answer: Regular maintenance includes visual inspections for leaks or damage, ensuring that mounting hardware is secure, and checking for any signs of wear or corrosion. Some shock absorbers may require periodic replacement of seals or fluids. Refer to the manufacturer’s maintenance schedule for specific recommendations to keep the shock absorber in optimal working condition.

- Question: What are common applications for fixed-type shock absorbers?

- Answer: They are commonly used in industrial machinery, automotive systems, robotics, and conveyor systems. These shock absorbers are ideal for applications where consistent damping is necessary, such as in assembly lines, packaging machinery, and any equipment that undergoes frequent or heavy impacts.

- Question: How does a fixed-type shock absorber extend the lifespan of machinery?

- Answer: By absorbing and dissipating the kinetic energy from impacts, fixed-type shock absorbers reduce the stress and strain on machinery components. This helps prevent wear and tear, minimizes the risk of mechanical failure, and ensures smoother operation, thereby extending the lifespan of the equipment and reducing maintenance costs.

How can we improve?

How can we improve?