(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 28/7/2024 to 6:00 29/7/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

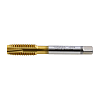

Point Taps(Screw size (Nominal):M5)

[What is a point tap?]

It is a groove-shaped cutting tap that discharges chips in the tap traveling direction, and is ideal for machining "through holes". It is characterized by low cutting torque as there are few obstacles to the chips. There are two types of materials, mainly HSS (= high speed steel) and carbide: HSS is tough and hard to break and carbide is abrasion resistant.

Configure

Specification/Dimensions

-

Screw size (Nominal)

- No.0

- No.0UN

- No.10

- No.1

- No.1UN

- No.10UN

- No.10UNJ

- No.10-32UNF

- No.10-24UNC

- No.12UN

- No.2

- No.2UN

- No.3

- No.3UN

- No.4

- No.4UN

- No.4-40UNC

- No.5

- No.5UN

- No.5-40UNC

- No.6

- No.6UN

- No.6UNJ

- S0.6

- No.6-32UNC

- S0.7

- No.8

- No.8UN

- No.8UNJ

- S0.8

- No.8-32UNC

- S0.9

- 1

- 1UN

- G1

- M1

- W1

- 1"1/2UN

- W1"1/2

- 1 1/4

- 1"1/4UN

- W1"1/4

- 1 1/8

- 1"1/8UN

- W1"1/8

- 1/2

- 1/2UN

- 1/2UNJ

- G1/2

- W1/2

- 1/2-20UNF

- 1/2-13UNC

- W1"3/4

- 1"3/8UN

- W1"3/8

- 1/4

- 1/4UN

- 1/4UNJ

- G1/4

- SM1/4

- W1/4

- 1/4-28UNF

- 1/4-20UNC

- 1/4W20

- W1"5/8

- W1"7/8

- 1/8UN

- G1/8

- SM1/8

- W1/8

- M1.1

- M1.2

- M1.4

- M1.6

- M1.7

- M1.8

- 2

- M2

- M2.0

- W2

- M2.2

- M2.3

- M2.5

- M2.6

- M3

- M3.0

- M3

- STI M3

- 3/4

- 3/4UN

- G3/4

- W3/4

- 3/4-16UNF

- 3/4-10UNC

- 3/8

- 3/8-UNJ

- 3/8UN

- 3/8UNJ

- G3/8

- W3/8

- 3/8-24UNF

- 3/8-16UNC

- 3/16

- 3/16UN

- SM3/16

- W3/16

- 3/32

- SM3/32

- W3/32

- M3.5

- 4M

- M4

- M4.0

- M4

- STI M4

- M4.5

- 5M

- M5

- M5.0

- M5

- STI M5

- 5/8

- 5/8UN

- W5/8

- 5/8-18UNF

- 5/8-11UNC

- 5/8W11

- 5/16

- 5/16UN

- 5/16UNJ

- W5/16

- 5/16-24UNF

- 5/16-18UNC

- 5/16W18

- W5/32

- M5.5

- 6UN

- M6

- M6.0

- M6

- STI M6

- M7

- 7/8

- 7/8UN

- W7/8

- 7/8-14UNF

- 7/8-9UNC

- 7/16

- 7/16UN

- 7/16UNJ

- W7/16

- 7/16-20UNF

- 7/16-14UNC

- 7/32

- W7/32

- 8UN

- M8

- M8.0

- M8

- STI M8

- M9

- 9/16

- 9/16UN

- W9/16

- 9/16-18UNF

- 9/16-12UNC

- SM9/32

- SM9/64

- 10UN

- M10

- M10.0

- M10

- STI M10

- M11

- 11/64

- SM11/64

- M12

- M12.0

- M12

- STI M12

- M13

- M14

- M14.0

- M14

- M15

- SM15/64

- M16

- M16.0

- M16

- M17

- M18

- M18

- M19

- M20

- M20

- M22

- M22

- M23

- M24

- M24

- M25

- M26

- M27

- M28

- M30

- M32

- M33

- M35

- M36

- M38

- M39

- M40

- M42

- M45

- M48

-

Screw Types

- Meter

- unified

- Whitworth

- Sewing Machine

- Parallel for Pipes

- Miniature

-

work material

- Low-Carbon Steel (carbon alloy less than 0.25%)

- Medium carbon steel (carbon content 0.25 to 0.45%)

- High Carbon Steel (C with a content over 0.45%)

- Alloy Steel (SCM)

- Stainless steel (SUS)

- Quenched and tempered steel (25 to 35 HRC)

- Quenched and tempered steel (35 to 45 HRC)

- Quenched and tempered steel (45 to 55 HRC)

- High Hardness Steel (50-60 HRC)

- Tool Steel (Before SKD Hardening)

- Steel casting (SC)

- Cast Iron (FC)

- Ductile Cast Iron (FCD)

- Copper (Cu)

- Brass (Bs)

- Brass cast iron (BsC)

- Bronze (Pb)

- Aluminum Rolled Material (AL)

- Aluminum Alloy Casting (AC, ADC)

- Magnesium Alloy (MC)

- Zinc Alloy Casting (ZDC)

- Titanium Alloy (Ti-6Al-4V, etc)

- Nickel-based alloy (Inconel, etc.)

- Thermoplastic plastic (vinyl chloride, nylon, etc.)

-

Pitch (P), Number of Threading(mm)

-

Tool Material Type

-

Tap Type

-

Hole type

-

Chamfer threads (Lcf)

-

Coating Type

-

Coating Y/N

-

Overall Length (L)(mm)

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

- 64 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Model A Tap Series, Pointed Tap A-POT

OSG

Thanks to its stable chip ejection capability, it can be used with various materials, as well as a wide range of cutting regions and devices. Point tap with point grooves used for through holes.From: ฿ 557.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/12/2024

Until 31/12/2024 Until 31/12/2024

Until 31/12/2024Pointed Tap Series, General Purpose EX-POT

OSG

For general use, ideal with carbon steel, alloy steel, and non-ferrous metals for cutting materials where the metal waste forms a continuous coil. Chips are reliably pushed forward so that they don't get in the wayFrom: ฿ 179.00 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/07/2024

Until 31/07/2024 Until 31/07/2024

Until 31/07/2024Pointed Tap for Stainless Steel use EX-SUS-POT

OSG

Offers superb sharpness and durability. Can be used to drill holes in difficult-to-cut stainless steel.From: ฿ 242.00 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/07/2024

Until 31/07/2024 Until 31/07/2024

Until 31/07/2024Pointed Tap for General Application (with OX)_EX-H-POT

OSG

For standard point taps, it is used when the protruding length of the screw is insufficient.From: ฿ 225.00 Special Price Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

YAMAWA MFG

■ The chips from the tap's cutting chamfer are pushed forward. This isoptimal for through hole tapping where there are no obstructions createdby the chip.

■Straight flutes are shallow so the taps strength is very high.From: ฿ 340.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/07/2024

Until 31/07/2024 Until 31/07/2024

Until 31/07/2024Pointed Tap Series TiN Coating TIN-POT

OSG

Features a wide range of uses, but especially suitable for high-speed tapping of stainless steel, tempered material, etc.From: ฿ 524.00 Special Price Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

From: ฿ 684.46 Days to Ship: 31 Day(s)

31 Day(s)

-

You can add up to 6 items per a category to the compare list.

Spiral Point Tap, Ni-Based Super Heat Resistant Alloys, NI-POT-M12/-NO10, 3 Grooves

OSG

Exerts power in Ni-base heat-resistant alloy (Inconel® 718, etc.) of 40 to 45 HRC aged after undergoing a solution heat treatment, used in such fields as aircraft, aerospace, and chemical industriesFrom: ฿ 532.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

LH Spiral SYNCHRO Tap for Aluminum_HS-AL-RFT

OSG

Exclusively for machines with a full-lead feed mechanism, it is capable of high-speed, high-precision female threading of aluminum and aluminum alloy.From: ฿ 454.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

For Pointed Tap for Titanium Alloy V-TI-POT

OSG

Enables processing with high durability, efficiency, and stability in titanium alloy (Ti-6Al-4V, etc.) of 40 to 45 HRC aged after undergoing a solution heat treatment, used in such fields as aircraft, aerospace, and chemical industriesFrom: ฿ 905.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Insert Screw Thread Tap_EX-HL-POT

OSG

Used for thread tapping of female threads by inserting the insert (helical coil) into a through holeFrom: ฿ 509.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/07/2024

Until 31/07/2024 Until 31/07/2024

Until 31/07/2024Spiral Pointed Taps for Stainless Steels_SU+PO

YAMAWA MFG

■ The SU+PO/SU-PO taps are designed for stainless steel that causes work harden easily. The cuttinggeometry is also suited for tapping through holes in chromium steel and molybdenum steel.

■To prevent chip welding, the tap's surface is oxidized.From: ฿ 317.00 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Pointed Tap for Deep Holes with Long Shank_EX-LT-DH-POT

OSG

The through hole has a particularly long tapping length and is suitable for work materials that are susceptible to seizure.

[Specifications]

[Shape] Point tap.

[Screw type] metric.

[Chamfer threads] 4 P.

[Work Material] Low-Carbon Steel (C Content of 0.25% or Less) / Medium-Carbon Steel (C Content 0.25 - 0.45%) / Alloy Steel (SCM) / Cast Steel (SC) / Thermoplastic (PVC, Nylon etc.)

[No. of Grooves] 3.

[Coating Type] Non.From: ฿ 805.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

TiN Coated High-Speed Steel Point Tap【1-5 Pieces Per Package】

MISUMI

[Features]

·Can be used for through hole machining

·It can handle a wide range of work materials, but is especially effective for tapping steel alloy and stainless steel, etc.

·Excellent abrasion resistance and chip-weld resistance due to TiN coating

·Long shank type ideal for drilling deep thread holes (G-LS-POT)From: ฿ 352.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

MT Series High-Speed Steel Point Tap

MISUMI

[New Item] A universal tap that can accommodate a wide range of work materials from general steel to aluminum and stainless steel.

The unique edge shape suppresses the collapse of the internal thread and eliminates the trouble of tapping.

[Slide Discount] Great deals are available on the purchase of more than 5 pieces.From: ฿ 248.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/07/2024

Until 31/07/2024 Until 31/07/2024

Until 31/07/2024Long Shank・General Application_EX-LT-POT

OSG

For standard point taps, it is used when the protruding length of the screw is insufficient.From: ฿ 489.00 Special Price Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

LH Spiral SYNCHRO Tap with JIS Shank_J-HS-RFT

OSG

Exclusively for machines with a full-lead feed mechanism, it is capable of high-speed, high-precision through-hole tapping.From: ฿ 935.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

Pointed Tap for Thin Plate EX-SS-POT

OSG

Ideal for tapping soft steel thin plates (through holes) with a tensile strength of 700 N/mm² or less. A beautiful finished surface is obtained as the generation of punch hole and bearing hole whiskers, flashes, or chipping can be kept to a minimumFrom: ฿ 346.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Taps, Oxidized_PO-OX

YAMAWA MFG

■ The +PO is a spiral pointed tap for through holetapping and is suitable for synchronous feedprocessing in middle to high thread processingof soft steel materials whose chips easily weldto the taps thread such as low carbon steels.From: ฿ 446.70 Days to Ship: 20 Day(s)

20 Day(s)

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Insert Screw Thread Tap with Long Shank_HL-LT-POT

OSG

Used for thread tapping of female threads by inserting the insert (helical coil) into a through holeFrom: ฿ 840.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

OSG

Exclusively for machines with a full-lead feed mechanism, it is capable of high-speed, high-precision through-hole tapping.From: ฿ 769.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

TRUSCO

[Features]

· High-speed tapping is possible.

· Oxidization treated.

· Work materials: General steel, low-medium carbon steel, alloy steel.

[Applications]

· For through hole finish work.From: ฿ 234.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Carbide Taps for Hard Materials_EH-CT

YAMAWA MFG

■Ideal for high hardness steel tapping from 45 to 55 HRC. For hot mold SKS 3 and SKD 11.

■The ultra fine grain cemented carbide is superior in abrasion resistance and impact resistance.

■Better concentricity improves the accuracy of the entire tap and roundness of the shank.

■ Recommended tapping length is "Major diameter size x 1.5" or less 5P chamfer for better tool life.

■For the bored hole diameter, the maximum minor diameter of a 6H internal thread diameter maximum value is recommended.From: ฿ 3,476.58 Days to Ship: 15 Day(s)

15 Day(s)

-

You can add up to 6 items per a category to the compare list.

High-Speed Steel Point Tap【10 Pieces Per Package】

MISUMI

[Features]

·High-speed steel uncoated spiral point tap

·Can be used for through hole machining

·Effective for work materials with continuous cutting chip such as carbon steel and steel alloyFrom: ฿ 1,128.23 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

OSG

CrN coating with superior wear resistance and anti-weldability for copper has been applied, with HSSE material used to achieve a long machining life for copper.From: ฿ 648.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

Until 31/07/2024

Until 31/07/2024 Until 31/07/2024

Until 31/07/2024Pointed Tap for Difficult-To-Cut Materials CPM-POT

OSG

The work material is ideal for through hole drilling of high carbon steel, tool steel, forged alloy steel or tempered material with hardness of about 20 to 45 HRCFrom: ฿ 303.00 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

CPM Pointed Tap with Long Shank_CPM-LT-POT

OSG

The work material is ideal for through hole drilling of high carbon steel, tool steel, forged alloy steel or tempered material with hardness of about 20 to 45 HRCFrom: ฿ 845.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

ISHIHASHI

High molybdenum content for toughness, with superior high hardness, heat resistance, and wear resistance.From: ฿ 567.57 Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

ISHIHASHI

The cutting torque is extremely light thanks to a shear cut enabled by the spiral cutting edge and the wide angle.From: ฿ 858.55 Days to Ship: 10 Day(s)

10 Day(s)

-

You can add up to 6 items per a category to the compare list.

Until 31/07/2024

Until 31/07/2024 Until 31/07/2024

Until 31/07/2024YAMAWA MFG

■ A tap mainly used for tapping nuts with atapping machine.From: ฿ 971.58 Special Price Days to Ship: 1 Day(s)

1 Day(s)

-

You can add up to 6 items per a category to the compare list.

Long Shank Spiral Pointed Taps_LS-PO

YAMAWA MFG

■ Long shank spiral pointed taps for tappingthreads in deep holes that cannot be reachedwith a standard overall length.From: ฿ 1,015.27 Days to Ship: 20 Day(s)

20 Day(s)

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Taps for Hard-to-Machine Materials_EH-PO

YAMAWA MFG

■ The EH-PO taps are suitable for high hardness materials from 30 to 45 HRC in high carbon steel, alloy steel forging, temperingmaterial and mold materials.

■ Tool life is greatly improved using a cutting edge shape suitable for difficult to machine materials. The tap exhibits excellent wear resistance.

■For through hole applications.From: ฿ 424.14 Days to Ship: 15 Day(s)

15 Day(s)

-

You can add up to 6 items per a category to the compare list.

NACHI(FUJIKOSHI)

[Features]

・ Used when the protrusion length is insufficient with standard size.From: ฿ 791.00 Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

Long Shank Short Spiral Pointed Taps for Stainless Steels_LS-SU-S-PO

YAMAWA MFG

■ Long shank spiral pointed tap suitable forstainless steels tending to cause work hardenand sticky, as well as chrome steels andmolybdenum steels. Through hole use. Tapping of rather deep holes is possible.From: ฿ 1,004.85 Days to Ship: 6 Day(s)

6 Day(s)

-

You can add up to 6 items per a category to the compare list.

Long Shank Spiral Pointed Taps with Long Neck_LS-PO-K

YAMAWA MFG

■ Long shank spiral pointed taps with long neckfor tapping threads in deep holes that cannot bereached with a standard overall length. The longneck enables deep hole tapping.From: ฿ 903.29 Days to Ship: 20 Day(s)

20 Day(s)

-

You can add up to 6 items per a category to the compare list.

From: ฿ 708.43 Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

HR Coated Pointed Tap for Nickel Alloy_WHR-NI-POT

OSG

The application of an HR coating with a high melt sticking resistance to nickel-base alloys achieves a long life even on age hardened nickel-base alloys (40 to 45 HRC)From: ฿ 1,182.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

Pointed Tap TiN coated with Long Shank_TIN-LT-POT

OSG

Features a wide range of uses, but especially suitable for high-speed tapping of stainless steel, tempered material, etc.From: ฿ 983.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

Pointed Tap for Stainless Steels with Long Shank_EX-LT-SUS-POT

OSG

With excellent sharpness and durability, it is used for stainless steel through holes where poor machinability is a problem.From: ฿ 602.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/07/2024

Until 31/07/2024 Until 31/07/2024

Until 31/07/2024LH Spiral SYNCHRO Tap with Long Shank_HS-LT-RFT

OSG

Exclusively for machines with a full-lead feed mechanism, it is capable of high-speed, high-precision through-hole tapping.From: ฿ 1,222.00 Special Price Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

Until 31/07/2024

Until 31/07/2024 Until 31/07/2024

Until 31/07/2024Pointed Tap for Deep Holes EX-DH-POT

OSG

Particularly suitable for workpieces which are easily scorched because the screw tapping length is particularly long.From: ฿ 273.00 Special Price Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

WALTER PROTOTYP

Suitable for high precision through-hole thread processing up to screw depths of 3 x D. Suitable for long chipping materials of 350-1,200 N/mm² and up to 36 HRC.From: ฿ 1,066.00 Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

WALTER PROTOTYP

Suitable for high precision through-hole thread processing up to screw depths of 3 x D. Suitable for long chipping materials of 350-1,200 N/mm² and up to 36 HRC.From: ฿ 1,599.00 Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

WALTER PROTOTYP

Suitable for high precision through-hole thread processing up to screw depths of 2 x D. Suitable for long chipping materials of 700-1,400 N/mm² and up to 44 HRC.From: ฿ 672.97 Days to Ship: 14 Day(s)

14 Day(s)

-

You can add up to 6 items per a category to the compare list.

From: ฿ 497.54 Days to Ship: 31 Day(s)

31 Day(s)

-

You can add up to 6 items per a category to the compare list.

Machine Nut Tap, for Metric Coarse Thread (Angle: 60°)

SKC

[Applications]

Can be used to machine nuts.

[Features]

For right-hand coarse threads.From: ฿ 928.08 Days to Ship: 31 Day(s)

31 Day(s)

-

You can add up to 6 items per a category to the compare list.

ISHIHASHI

For tapping when the depth is roughly twice or more the nominal diameter, in order to reduce frictional resistance and to improve the supply of cutting oil, the groove is designed with a shorter threaded portion to improve the discharge of chips.From: ฿ 415.31 Days to Ship: 31 Day(s)

31 Day(s)

-

You can add up to 6 items per a category to the compare list.

From: ฿ 889.00 Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

From: ฿ 463.00 Days to Ship: 31 Day(s)

31 Day(s)

-

You can add up to 6 items per a category to the compare list.

Point Tap for Through Holes 1015

GUHRING

[Features]

· JIS standard compliant tap for through holes.

· Supports a wide range of work materials from general steel to stainless steel.From: ฿ 749.00 Days to Ship: 24 Day(s)

24 Day(s)

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Taps for Left Hand Threads_PO-V

YAMAWA MFG

■ Adopting the optimum coating for the tappingcondition.From: ฿ 657.11 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Taps for Nickel Base Alloys_ZEN-P

YAMAWA MFG

■ The tap is produced from high grade powder high speed steel material that has excellent heat resistance and abrasion resistance properties.

■ Cutting edge geometry is designed to accommodate for thread shrinkage and the high temperature of difficult to machine materials.

■Utilizes the appropriate flute shape and rake angles for nickel base alloy to allow a smooth discharge of chips.

■YAMAWA uses the ideal surface treatment to prevent chip welding and abrasion.

■Compensating for diameter shrinkage of the internal screw thread, the tap is produced moderately oversize.From: ฿ 606.52 Days to Ship: 10 Day(s)

10 Day(s)

-

You can add up to 6 items per a category to the compare list.

Plus Series Spiral Pointed Taps_+PO

YAMAWA MFG

■ The +PO is a spiral pointed tap for through holetapping and is suitable for synchronous feedprocessing in middle to high tapping speed.From: ฿ 273.96 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Long Shank Spiral Pointed Taps, Coated_LS-PO-V

YAMAWA MFG

■ Long shank coated spiral fluted taps for tappingthreads in deep holes that cannot be reachedwith a standard overall length.From: ฿ 1,151.33 Days to Ship: 6 Day(s)

6 Day(s)

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Taps for High Carbon Steels_HC+PO

YAMAWA MFG

■ The HC+PO/HC-PO is a spiral pointed tap suitable for the tapping medium and high hardnessworkpiece materials up to 35 HRC in high carbon steel such as S55C.From: ฿ 339.21 Days to Ship: 1 Day(s)

1 Day(s)

-

You can add up to 6 items per a category to the compare list.

Short Spiral Pointed Taps for Deep Hole Use_S-PO

YAMAWA MFG

■ S-PO is the spiral pointed tap having shortthread portion which reduces friction and makessmooth coolant supply, and is suitable for suchdeep holes which are deeper than 2.5 times ofthe nominal dia.From: ฿ 368.27 Days to Ship: 1 Day(s)

1 Day(s)

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Carbide Taps_N-CT-PO

YAMAWA MFG

■ The N-CT-PO is a cemented carbide spiral flutetap most suitable for blind hole mass productionof aluminum castings (AC), aluminum die cast(ADC), zinc die cast (ZDC) etc.From: ฿ 4,751.12 Days to Ship: 6 Day(s)

6 Day(s)

-

You can add up to 6 items per a category to the compare list.

General Application(with OX)_EX-LT-H-POT

OSG

[Specifications]

· Shape: Point tap

· Screw type: metric

· Work Material: Low Carbon Steel (less than 0.25% carbon alloy) [◎] / Medium Carbon Steel (0.25 to 0.45% carbon alloy) [○] / High Carbon Steel (over 0.45% carbon alloy) [○] / Alloy Steel (SCM) [○] / Cast Steel (SC) [○] / Thermoplastic Plastic (Vinyl Chloride, Nylon, etc.) [○]From: ฿ 602.00 Days to Ship: 91 Day(s)

91 Day(s)

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Tap with Long Shank_A-LT-POT

OSG

Thanks to its stable chip ejection capability, it can be used with various materials, as well as a wide range of cutting regions and devices. Point tap with point grooves used for through holes.From: ฿ 1,000.00 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

NACHI(FUJIKOSHI)

[Features]

・ A tap for through-holes, supporting various cutting speeds, machinery, and work materials.From: ฿ 580.00 Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

From: ฿ 329.46 Days to Ship: 31 Day(s)

31 Day(s)

-

You can add up to 6 items per a category to the compare list.

Spiral Pointed Taps for General Purpose_IPO

YAMAWA MFG

■ IPO is the best tap for through holes to be used with lowercutting speed on drilling machines.

■ Use for threading of the iron(SPC or SS400) products usedin our daily life.

■ Surface treated. Oxidization, the most suitable surfacetreatment for iron products.

■ Suitable for internal threadcutting in small quantity, such astapping of test pieces.

■ Having spiral points in thechamfer portion, IPO ejects chipsforward in the tapping directionand is for through hole use.From: ฿ 284.48 Days to Ship: 1 Day(s)

1 Day(s)

-

You can add up to 6 items per a category to the compare list.

PROCHI

[Features]

· Cutting chips are curled into a coil-shape and discharged from the front side.

· Increased rigidity to help prevent breakage.

· Suitable for use with high-speed tapping.

[Applications]

· Through holes

· Work material: suitable for stainless steel, heat-resistant steel and nickel chromium manganese steel. Also suitable for use with carbon steel and alloy steel.From: ฿ 242.74 Days to Ship: 31 Day(s)

31 Day(s)

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Screw size (Nominal) |

| Screw Types |

| work material |

| Pitch (P), Number of Threading(mm) |

| Tool Material Type |

| Tap Type |

| Hole type |

| Chamfer threads (Lcf) |

| Coating Type |

| Coating Y/N |

| Overall Length (L)(mm) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | OSG | OSG | OSG | OSG | YAMAWA MFG | OSG | NACHI(FUJIKOSHI) | OSG | OSG | OSG | OSG | YAMAWA MFG | OSG | MISUMI | MISUMI | OSG | OSG | OSG | YAMAWA MFG | OSG | OSG | TRUSCO | YAMAWA MFG | MISUMI | OSG | OSG | OSG | ISHIHASHI | ISHIHASHI | YAMAWA MFG | YAMAWA MFG | YAMAWA MFG | NACHI(FUJIKOSHI) | YAMAWA MFG | YAMAWA MFG | YAMAWA MFG | OSG | OSG | OSG | OSG | OSG | WALTER PROTOTYP | WALTER PROTOTYP | WALTER PROTOTYP | ISHIHASHI | SKC | SKC | ISHIHASHI | ISHIHASHI | GUHRING | GUHRING | YAMAWA MFG | YAMAWA MFG | YAMAWA MFG | YAMAWA MFG | YAMAWA MFG | YAMAWA MFG | YAMAWA MFG | OSG | OSG | NACHI(FUJIKOSHI) | NACHI(FUJIKOSHI) | YAMAWA MFG | PROCHI |

| Product Series | Spiral Point Tap, Ni-Based Super Heat Resistant Alloys, NI-POT-M12/-NO10, 3 Grooves | TiN Coated High-Speed Steel Point Tap【1-5 Pieces Per Package】 | Spiral Pointed Insert Screw Thread Tap with Long Shank_HL-LT-POT | Long Shank Short Spiral Pointed Taps for Stainless Steels_LS-SU-S-PO | Pointed Tap for Stainless Steels with Long Shank_EX-LT-SUS-POT | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| From | ฿ 557.00 | ฿ 179.00 Special Price On Sale Until 31/12/2024 | ฿ 242.00 Special Price On Sale Until 31/07/2024 | ฿ 225.00 Special Price On Sale Until 31/07/2024 | ฿ 340.00 | ฿ 524.00 Special Price On Sale Until 31/07/2024 | ฿ 684.46 | ฿ 532.00 | ฿ 454.00 | ฿ 905.00 | ฿ 509.00 | ฿ 317.00 Special Price On Sale Until 31/07/2024 | ฿ 805.00 | ฿ 352.00 | ฿ 248.00 | ฿ 489.00 Special Price On Sale Until 31/07/2024 | ฿ 935.00 | ฿ 346.00 | ฿ 446.70 | ฿ 840.00 | ฿ 769.00 | ฿ 234.00 | ฿ 3,476.58 | ฿ 1,128.23 | ฿ 648.00 | ฿ 303.00 Special Price On Sale Until 31/07/2024 | ฿ 845.00 | ฿ 567.57 | ฿ 858.55 | ฿ 971.58 Special Price On Sale Until 31/07/2024 | ฿ 1,015.27 | ฿ 424.14 | ฿ 791.00 | ฿ 1,004.85 | ฿ 903.29 | ฿ 708.43 | ฿ 1,182.00 | ฿ 983.00 | ฿ 602.00 | ฿ 1,222.00 Special Price On Sale Until 31/07/2024 | ฿ 273.00 Special Price On Sale Until 31/07/2024 | ฿ 1,066.00 | ฿ 1,599.00 | ฿ 672.97 | ฿ 406.24 | ฿ 497.54 | ฿ 928.08 | ฿ 415.31 | ฿ 889.00 | ฿ 463.00 | ฿ 749.00 | ฿ 657.11 | ฿ 606.52 | ฿ 273.96 | ฿ 1,151.33 | ฿ 339.21 | ฿ 368.27 | ฿ 4,751.12 | ฿ 602.00 | ฿ 1,000.00 | ฿ 580.00 | ฿ 329.46 | ฿ 284.48 | ฿ 242.74 |

| Days to Ship | Same day | Same day | Same day | 91 Day(s) | Same day | 5 Day(s) | 31 Day(s) | 91 Day(s) | 91 Day(s) | 91 Day(s) | Same day | Same day | Same day | Same day | Same day | 5 Day(s) | 91 Day(s) | Same day | 20 Day(s) | 91 Day(s) | 91 Day(s) | Same day | 15 Day(s) | Same day | 91 Day(s) | Same day | Same day | 12 Day(s) | 10 Day(s) | 1 Day(s) | 20 Day(s) | 15 Day(s) | 5 Day(s) | 6 Day(s) | 20 Day(s) | 12 Day(s) | 91 Day(s) | 91 Day(s) | Same day | 91 Day(s) | 91 Day(s) | 12 Day(s) | 12 Day(s) | 14 Day(s) | 1 Day(s) | 31 Day(s) | 31 Day(s) | 31 Day(s) | 12 Day(s) | 31 Day(s) | 24 Day(s) | Same day | 10 Day(s) | Same day | 6 Day(s) | 1 Day(s) | 1 Day(s) | 6 Day(s) | 91 Day(s) | Same day | 5 Day(s) | 31 Day(s) | 1 Day(s) | 31 Day(s) |

| Screw size (Nominal) | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 | M5 |

| Screw Types | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | Meter | - |

| work material | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[◎] / Alloy Steel (SCM)[◎] / Stainless steel (SUS)[◎] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[◎] / Ductile Cast Iron (FCD)[◎] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] | Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[◎] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Stainless steel (SUS)[◎] / Copper (Cu)[◎] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[◎] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Steel casting (SC)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Steel casting (SC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[◎] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Stainless steel (SUS)[◎] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] | Nickel-based alloy (Inconel, etc.)[◎] | Copper (Cu)[○] / Aluminum Rolled Material (AL)[◎] / Aluminum Alloy Casting (AC, ADC)[◎] / Zinc Alloy Casting (ZDC)[◎] | Titanium Alloy (Ti-6Al-4V, etc)[◎] | Aluminum Rolled Material (AL)[◎] / Aluminum Alloy Casting (AC, ADC)[◎] / Zinc Alloy Casting (ZDC)[◎] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Steel casting (SC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / Alloy Steel (SCM)[○] / Steel casting (SC)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / Alloy Steel (SCM)[◎] / Stainless steel (SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Tool Steel (Before SKD Hardening)[◎] / Steel casting (SC)[◎] / Cast Iron (FC)[◎] / Ductile Cast Iron (FCD)[◎] / Copper (Cu)[◎] / Brass (Bs)[◎] / Brass cast iron (BsC)[◎] / Bronze (Pb)[◎] / Aluminum Rolled Material (AL)[◎] / Aluminum Alloy Casting (AC, ADC)[◎] / Magnesium Alloy (MC)[◎] / Zinc Alloy Casting (ZDC)[◎] | Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[◎] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Steel casting (SC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[◎] / Zinc Alloy Casting (ZDC)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Stainless steel (SUS)[○] / Copper (Cu)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] | Aluminum Rolled Material (AL)[◎] / Aluminum Alloy Casting (AC, ADC)[◎] / Zinc Alloy Casting (ZDC)[◎] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Steel casting (SC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[◎] / Zinc Alloy Casting (ZDC)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / Alloy Steel (SCM)[○] / Steel casting (SC)[○] | Quenched and tempered steel (45 to 55 HRC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] | Stainless steel (SUS)[○] / Copper (Cu)[◎] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Aluminum Alloy Casting (AC, ADC)[○] | High Carbon Steel (C with a content over 0.45%)[◎] / Quenched and tempered steel (25 to 35 HRC)[◎] / Quenched and tempered steel (35 to 45 HRC)[◎] / Tool Steel (Before SKD Hardening)[◎] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] | High Carbon Steel (C with a content over 0.45%)[◎] / Quenched and tempered steel (25 to 35 HRC)[◎] / Quenched and tempered steel (35 to 45 HRC)[◎] / Tool Steel (Before SKD Hardening)[◎] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] | - | - | - | - | High Carbon Steel (C with a content over 0.45%)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Tool Steel (Before SKD Hardening)[○] / Copper (Cu)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Copper (Cu)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / Stainless steel (SUS)[○] | Medium carbon steel (carbon content 0.25 to 0.45%)[○] | Stainless steel (SUS)[○] | Nickel-based alloy (Inconel, etc.)[◎] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[◎] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Stainless steel (SUS)[◎] / Copper (Cu)[◎] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[◎] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Steel casting (SC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[◎] / Zinc Alloy Casting (ZDC)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / Alloy Steel (SCM)[○] / Steel casting (SC)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] | Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] | Titanium Alloy (Ti-6Al-4V, etc)[○] / Nickel-based alloy (Inconel, etc.)[○] | - | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Zinc Alloy Casting (ZDC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Zinc Alloy Casting (ZDC)[○] | - | - | - | - | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Cast Iron (FC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Steel casting (SC)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] | Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Ductile Cast Iron (FCD)[○] | Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Ductile Cast Iron (FCD)[○] | Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Steel casting (SC)[○] / Thermoplastic plastic (vinyl chloride, nylon, etc.)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[◎] / High Carbon Steel (C with a content over 0.45%)[◎] / Alloy Steel (SCM)[◎] / Stainless steel (SUS)[◎] / Tool Steel (Before SKD Hardening)[○] / Steel casting (SC)[◎] / Ductile Cast Iron (FCD)[◎] / Copper (Cu)[○] / Brass (Bs)[○] / Brass cast iron (BsC)[○] / Bronze (Pb)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] / Magnesium Alloy (MC)[○] / Zinc Alloy Casting (ZDC)[○] / Titanium Alloy (Ti-6Al-4V, etc)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Quenched and tempered steel (25 to 35 HRC)[○] / Quenched and tempered steel (35 to 45 HRC)[○] / Ductile Cast Iron (FCD)[○] / Copper (Cu)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Copper (Cu)[○] / Aluminum Rolled Material (AL)[○] / Aluminum Alloy Casting (AC, ADC)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[◎] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] | Low-Carbon Steel (carbon alloy less than 0.25%)[○] / Medium carbon steel (carbon content 0.25 to 0.45%)[○] / High Carbon Steel (C with a content over 0.45%)[○] / Alloy Steel (SCM)[○] / Stainless steel (SUS)[○] / Nickel-based alloy (Inconel, etc.)[○] |

| Pitch (P), Number of Threading(mm) | 0.5 ~ 0.8 | 0.5 ~ 0.9 | 0.8 ~ 0.9 | 0.8 | 0.5 ~ 0.8 | 0.8 | 0.5 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 ~ 0.9 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.9 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | - | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 ~ 0.9 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.5 ~ 0.8 | 0.5 ~ 0.8 | 0.8 | 0.8 | 0.8 |

| Tool Material Type | Powder high-speed steel | Vanadium High-Speed Steel | Vanadium High-Speed Steel | Vanadium High-Speed Steel | High-speed steel | Vanadium High-Speed Steel | High-speed steel | Powder high-speed steel | Vanadium High-Speed Steel | Powder high-speed steel | Vanadium High-Speed Steel | High-speed steel | Vanadium High-Speed Steel | Vanadium High-Speed Steel | Cobalt HSS | Vanadium High-Speed Steel | Vanadium High-Speed Steel | Vanadium High-Speed Steel | High-speed steel | Vanadium High-Speed Steel | Vanadium High-Speed Steel | Vanadium High-Speed Steel | Carbide | Vanadium High-Speed Steel | Vanadium High-Speed Steel | Powder high-speed steel | Powder high-speed steel | Cobalt HSS | - | High-speed steel | High-speed steel | Cobalt HSS | High-speed steel | High-speed steel | High-speed steel | Powder high-speed steel | Powder high-speed steel | Vanadium High-Speed Steel | Vanadium High-Speed Steel | Vanadium High-Speed Steel | Vanadium High-Speed Steel | High-speed steel | High-speed steel | Powder high-speed steel | - | - | - | - | - | High-speed steel | High-speed steel | High-speed steel | Powder high-speed steel | High-speed steel | High-speed steel | High-speed steel | High-speed steel | Carbide | Vanadium High-Speed Steel | Powder high-speed steel | High-speed steel | High-speed steel | High-speed steel | Vanadium High-Speed Steel |

| Tap Type | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap | Point tap |

| Hole type | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole / For blind hole | For through hole | For through hole | For through hole | For through hole | - | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For blind hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | - | - | - | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole | For through hole |

| Chamfer threads (Lcf) | 5P | 5P | 4P | 5P | 5P | 5P | 5 | 5P | 6P | 5P | 5P | 5P | 4P | 5P | 5P | 5P | 5P | 5P | 5P | 5P | 6P | 5P | 5P | 5P | 5P | 5P | 5P | - | - | 29P | 5P | 4.5P | 5 | 4.5P | 4.5P | - | 5P | 5P | 4P | 6P | 4P | - | - | - | - | - | - | - | - | - | - | 5P | 4.5P | 5P | 5P | 5P | 5P | 5P | 5P | 5P | 5 | 5 | 5P | 5 |

| Coating Type | Other | Non-Coated | Non-Coated | Non-Coated | - | TiN | - | Non-Coated | Non-Coated | TiCN | Non-Coated | - | Non-Coated | TiN | Non-Coated | Non-Coated | TiN | Non-Coated | - | Non-Coated | TiN | - | TiAlN | - | CrN | Non-Coated | Non-Coated | Non-Coated | Other | - | - | - | - | Other | - | Other | Other | TiN | Non-Coated | TiN | Non-Coated | Non-Coated | TiCN | Non-Coated | Other | - | - | Non-Coated | Other | Non-Coated | TiN | TiN | - | - | TiN | - | - | - | Non-Coated | Other | TiCN | Non-Coated | Other | Other |

| Coating Y/N | Available | NA | NA | NA | NA | Available | - | NA | NA | Available | NA | NA | NA | Available | NA | NA | Available | NA | NA | NA | Available | - | Available | NA | Available | NA | NA | NA | Available | NA | NA | NA | NA | Available | NA | - | Available | Available | NA | Available | NA | NA | Available | NA | Available | - | - | NA | Available | NA | Available | Available | NA | NA | Available | NA | NA | NA | NA | Available | Available | NA | Available | Available |

| Overall Length (L)(mm) | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 62 | 60 | 120 | 60 ~ 100 | 60 | 100 ~ 150 | 60 | 60 | 60 | 100 | 60 | 60 | 60 | 60 | 60 | 60 | 100 | 60 | 100 | 110 | 120 | 60 | 150 | 100 ~ 150 | 100 | 70 | 60 | 100 | 100 ~ 150 | 100 ~ 150 | 60 | 60 | 60 | 60 | 60 | 60 | 110 | 60 | 100 | 60 | 60 | 60 | 60 | 60 | 100 | 60 | 60 | 60 | 100 | 100 ~ 150 | 60 | - | 60 | - |

Loading...

How can we improve?

How can we improve?