MVX Drill Bit (Internal Oil Supply Type)

Caution

- Product pictures are for reference only !!!!

- Please check product specification before order !!!!

Product Description

MVX drill (internal oil supply type) with replaceable flute.

[Features]

· Four-corner specification inserts, so economical.

· Combination insert with outer edge CVD and inner edge PVD.

· High rigidity body implementing L/D = 6 deep hole drilling.

· Uses abrasion-resistance CVD-coated type carbide for the outer flute with high cutting speed.

· Highly stable PVD coated carbide grades are provided each to inner cutting edge with low cutting speed.

· Optimizes friction balance to implement long service lifespan.

[Application]

· For opening holes in aluminum / cast iron, stainless steel, hardened steel, aluminum alloy.

Basic specifications and features of the product

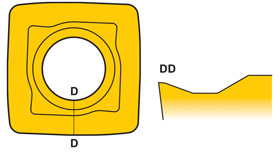

Complete 4-corner specification

Economical insert with complete 4-corner specification.

Combination insert of outer edge CVD & inner edge PVD A

CVD coated carbide grade with high friction resistance is placed on the outer edge with high cutting speed, and a PVD coated carbide grade with high stability is placed on the inner edge with low cutting speed. This optimizes friction balance and achieves long life.

High-rigidity The surface hardness of the body

has been increased, and by increasing the abrasion resistance to chips, a long tool life has been achieved.

Optimal insert placement suppresses deformation and chattering of the holder.

This makes it possible to drill holes with a maximum L/D = 6.

Original chipbreaker design

Supports a wide range of work materials and machining forms.

Wiper edge

A wiper is provided on the outer peripheral cutting edge to achieve good wall surface accuracy.

UM chipbreaker for all-round machining

US chipbreaker for stainless steel machining

●Key technology that realizes deep hole drilling of L/D=6

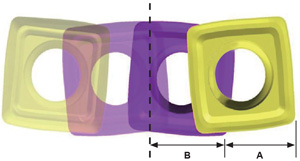

Optimal Insert Arrangement for

Outer and Inner Edges By optimizing the cutting ratios A and B of the outer and inner edges, deformation of the holder is suppressed.

In addition, by making the cutting ratio of A and B the same for all diameters, variation in performance for each diameter is reduced.

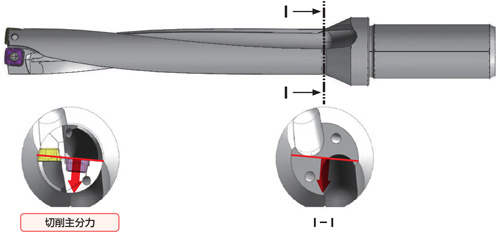

Optimal Groove Rift Position to Control Holder Deformation

At the groove cut-up position , thickening is provided in the direction of the main cutting force of the inner edge

to suppress deformation of the holder when the insert bites into the groove.

Adoption

of slanted coolant holes Supports chip evacuation from deep holes by adopting slanted coolant holes with relatively little loss of coolant momentum.

20% more discharge volume than conventional products

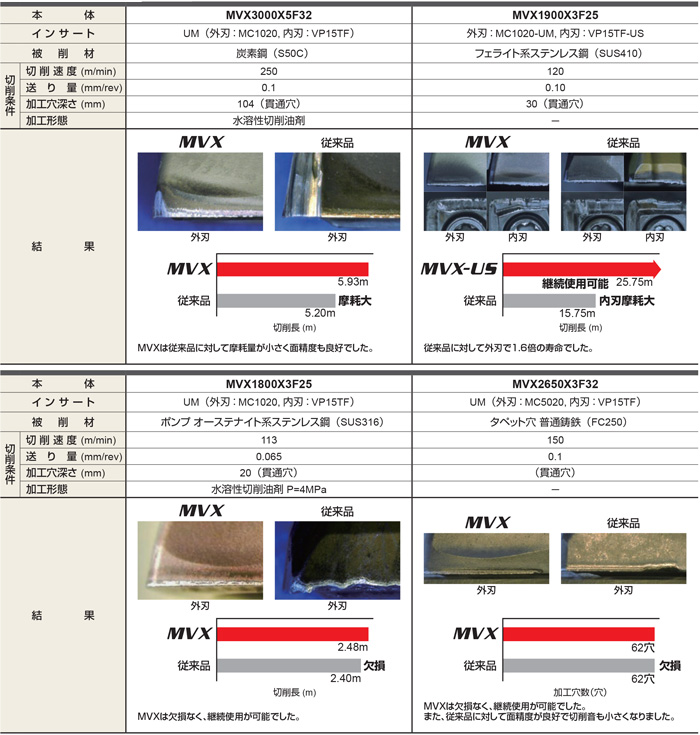

Performance/test information

· When machining stainless steel (SUS304)

using a US breaker for the inner blade, the tool life is doubled compared to conventional products.

Cutting length comparison

Cutting edge damage comparison

<Cutting conditions>

Drill: MVX3000X3F32 Insert : Outer edge MC1020

-UM

Inner edge VP15TF-US Work

material: SUS304

Cutting speed: 120m/min cutting fluid

・When machining carbon steel (S50C)

, MVX has about 3 times longer tool life than conventional products.

Cutting length comparison

Cutting edge damage comparison

<Cutting conditions>

Drill: MVX1900X3F25 Insert :

Outer edge MC1020-UM Inner

edge VP15TF-UM Work

material: S50C

Cutting speed: 220m/min cutting fluid

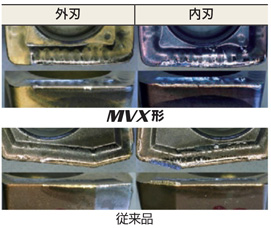

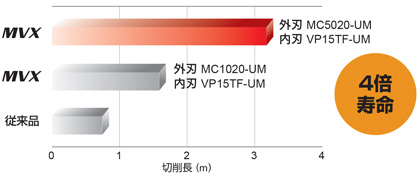

· Cast iron (FC250)

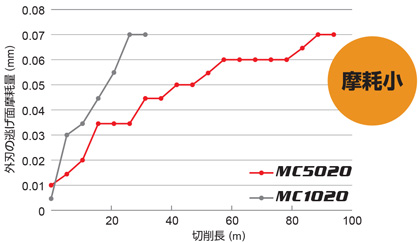

MVX drills have a long life even when machining cast iron, but by using the cast iron exclusive grade MC5020 for the outer edge, it is possible to further extend the life.

Cutting length comparison

<Cutting conditions>

Drill: MVX1900X3F25

Insert: Outer edge MC5020-UM

MC1020-UM

Inner edge VP15TF-UM Work material

: FC250

Cutting speed: 160m/min

Feed rate: 0.15mm/rev Drilling

depth: 50mm (through)

Form : Water-soluble cutting fluid

·

MC5020, a grade for machining ductile cast iron (FCD450), wears slower than the general-purpose grade MC1020, even when machining ductile cast iron, and has a long tool life.

Cutting length comparison

Cutting edge damage comparison

All cutting edge damage at VB=0.07mm

<Cutting conditions>

Drill: MVX1900X3F25

Insert: Outer edge MC5020-UM

MC1020-UM

Inner edge VP15TF-UM Work

material: FCD450

Cutting speed: 135m/min

Feed rate: 0.12mm/rev Drilling

depth: 50mm (through)

Form : Water-soluble cutting fluid

・Hardened steel (SKD61)

The UH chipbreaker enables stable machining and achieves twice the tool life of conventional products.

Comparison of the number of processed holes

<Cutting conditions>

Drill: MVX1700X3F20

Insert: Outer edge MC1020-UM

Inner edge DP8020-UH Work

material: SKD61 (45HRC)

Cutting speed: 50m/min

Feed rate: 0.08mm/rev Drilling

depth: 30mm (through hole)

Form : Water-soluble cutting fluid

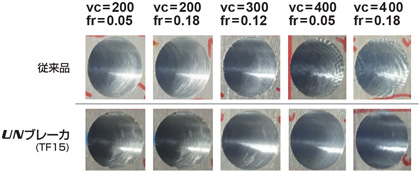

・Aluminum alloy machining (ADC12)

The UN chipbreaker suppresses ripping of the hole surface and can respond to changes in cutting speed.

<Cutting conditions>

Drill: MVX1700X5F20

Insert: Outer edge TF15-UN

Inner edge TF15-UN Work

material: ADC12

Cutting speed: 200-400m/min

Feed rate: 0.05-0.18mm/rev Drilling

depth: 40mm (blind hole )

Form of processing: Water-soluble cutting fluid

- Example of use

Maximum turning offset adjustment amount

| - | Processing tolerance (reference) (mm) | ||

|---|---|---|---|

| L/D | φ17-φ33 | φ33.5-φ47 | φ48-φ63 |

| 2, 3 | + 0.25 0 | + 0.3 0 | + 0.3 0 |

| 4, 5 | + 0.35 0 | + 0.4 0 | + 0.45 0 |

| 6 | + 0.45 0 | + 0.6 0 | - |

How to use/examples of use

how to use

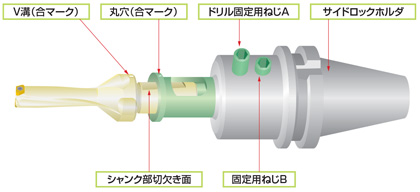

■ How to use the just-fit sleeve

(1) When inserting the drill into the side lock holder, align the V-groove on the outer periphery of the drill flange with the round hole on the outer periphery of the sleeve flange and the screws for fixing the drill on the side lock holder. Some drills do not have a V-groove, so in that case, align the notch of the drill shank with the round hole of the sleeve.(2) Fix the drill body directly through the opening of the sleeve with the drill fixing screw A of the side lock holder.

■ How to use the MVX drill

When using a lathe

*If the center height of the inner cutter is higher than the machine's X axis, the inner cutter may break.

(2) When adjusting the hole diameter by offsetting, adjust in the positive direction of the X axis (in the direction of expanding the hole diameter).

*We do not recommend adjusting the X-axis in the negative direction (reducing the hole diameter), as the holder may interfere with the hole.

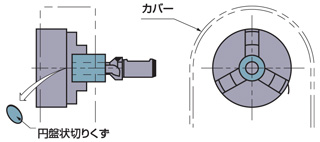

(3) When through-cutting is performed with a lathe, disc-shaped chips may be generated and scattered during penetration. For general-purpose lathes that do not have a cover, attach a cover to prevent danger.

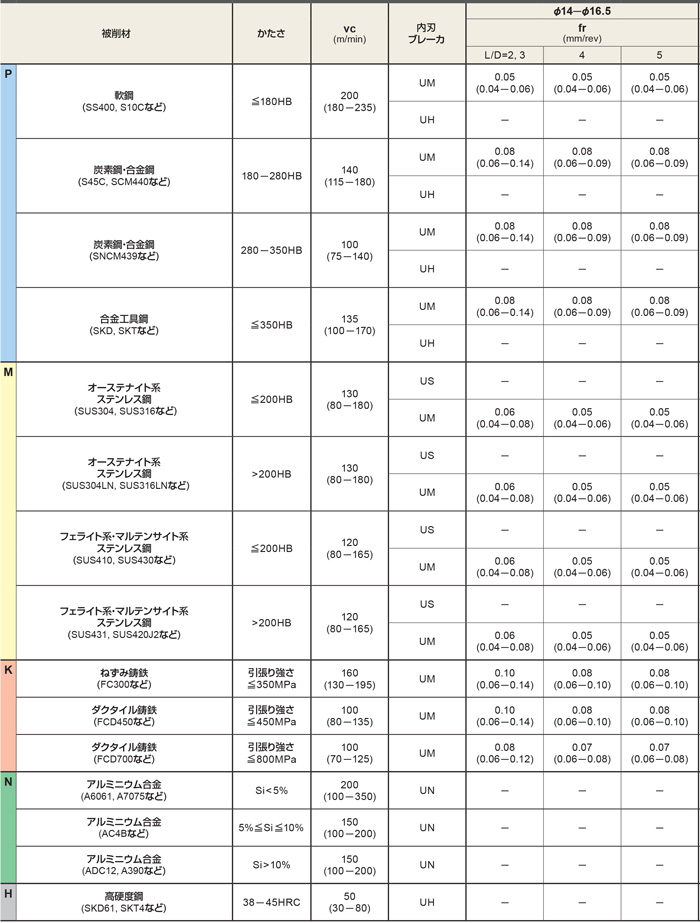

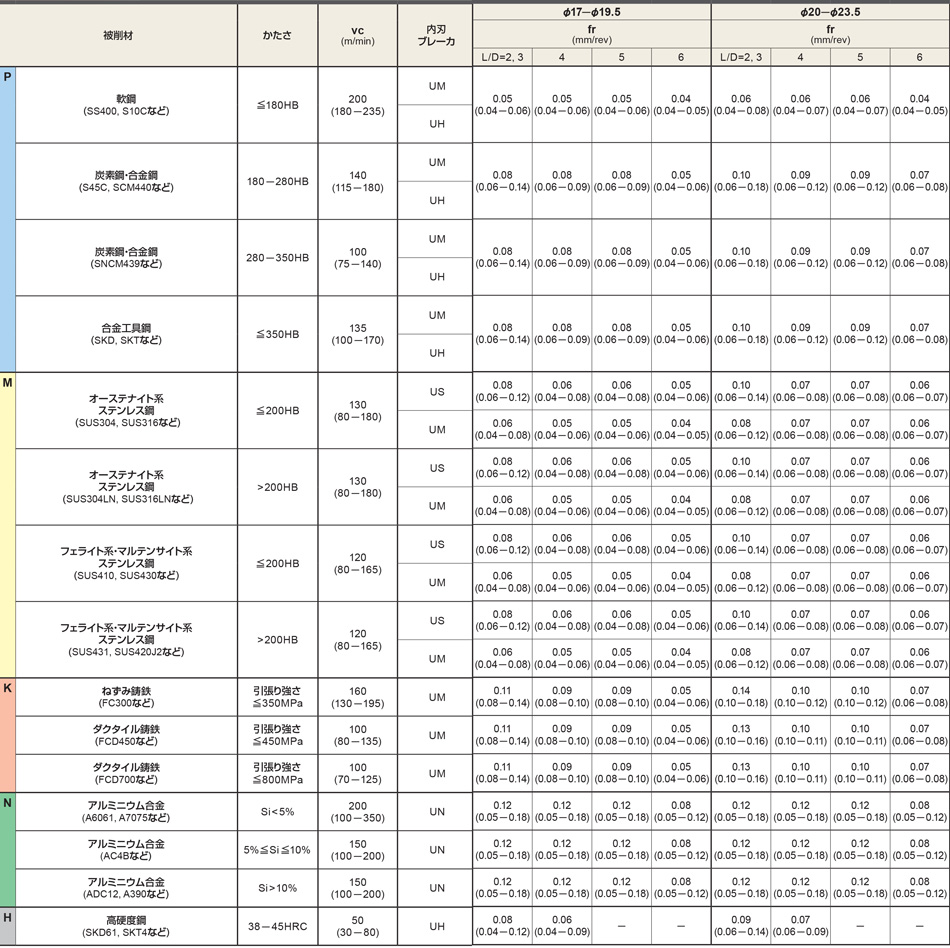

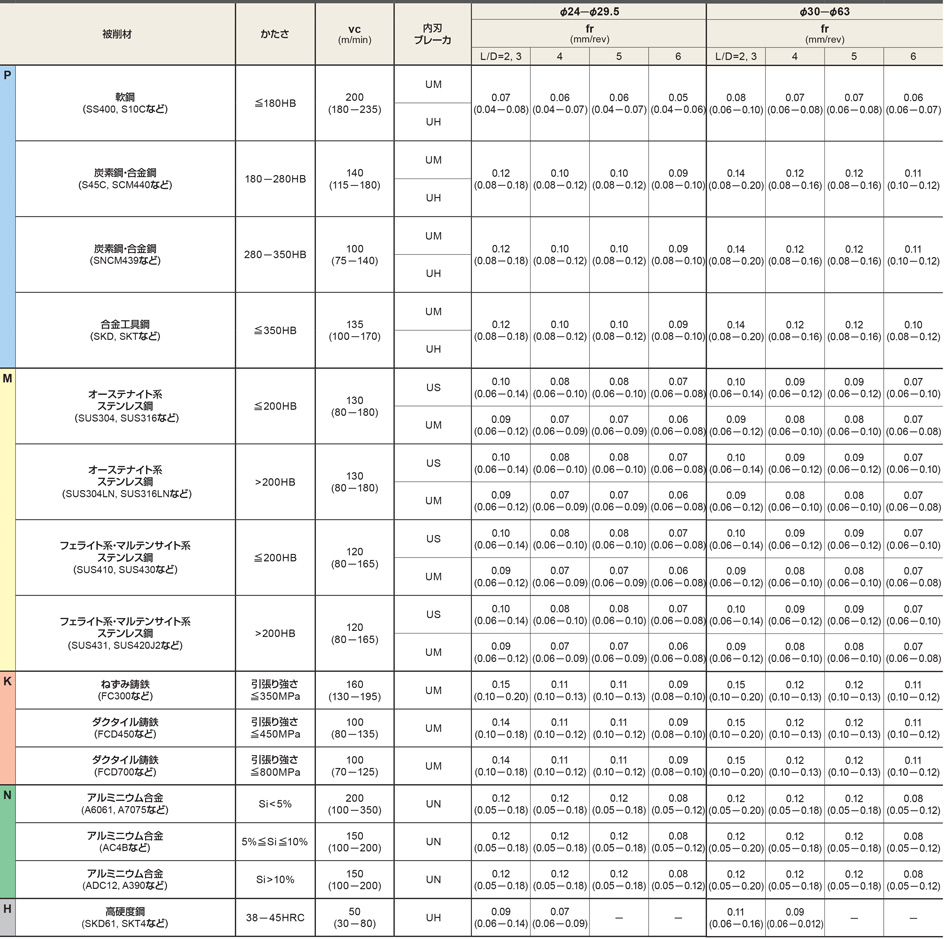

Recommended cutting conditions

Recommended cutting conditions table

- These cutting conditions are based on the manufacturer's recommended conditions and describe the rotation speed, feed rate, and depth of cut for each work material (general steel, alloy steel, tempered steel, hardened steel, stainless steel, aluminum, cast iron, etc.). Thing.

- Optimal machining conditions change depending on the machining environment (machine tool, tooling, etc.), so please check the machining conditions (machined surface, chatter, etc.) and make corrections before use.

vc = cutting speed median value (minimum value - maximum value)

fr = feed amount per revolution median value (minimum value - maximum value)

Unit: mm

Notes on cutting conditions

- When using VP15TF for the outer edge, reduce the cutting speed vc to about 70%.

- When using external coolant, the maximum machining depth should be L/D=3. Other machining depths are not recommended.

- When machining stainless steel, be sure to use internal coolant.

Applicable work material

- Steel, stainless steel, cast iron, nonferrous metals, hardened steel

Selection support information

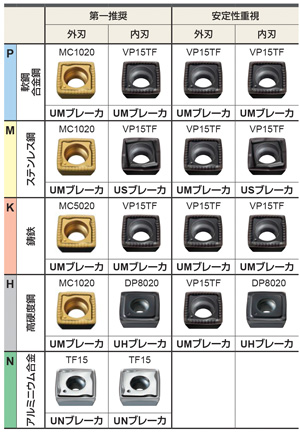

●Insert breaker

- US Chipbreaker for Stainless Steel Machining Inner Cutting Edge

Strengthened cutting edge and sharpness-focused variable shape cutting edge provide both chipping resistance and stainless steel machinability.

Composite R design improves cutting edge chipping resistance and adhesion resistance.

- General-purpose medium-to-high feed UM chipbreaker

's unique design achieves excellent chip control.

All-round machining of steel, stainless steel, cast iron, and hardened steel is possible.

- Reinforced edge type The UH breaker

's reinforced edge type and Ti-Al-Si coating enable stable machining even in unstable cutting of hardened steel (up to 45HRC) and general steel.

- For Aluminum Alloy Machining UN Breaker

The shape of the breaker emphasizes sharpness and the sharp edge is achieved by grinding the outer circumference for excellent chip control

. Aluminum welding is prevented by smoothing the rake face.

●Insert selection points

Due to the characteristics of drills, the closer to the center, the slower the cutting speed and the more likely it is to weld.

・For steel and cast iron,

select the UM breaker.

For high-efficiency machining (high-speed rotation), a CVD-coated carbide grade (steel: MC1020, cast iron: MC5020) with excellent wear resistance is used as the outer edge, and the inner edge has excellent adhesion resistance. A PVD-coated carbide grade (VP15TF) is recommended.

If the outer edge is prone to chipping, emphasize stability and use PVD-coated carbide grade (VP15TF) for both the outer and inner edges.

・

By using a UM breaker for the outer blade and a US breaker with improved adhesion and fracture resistance for stainless steel for the inner blade, excellent performance is achieved in machining stainless steel. .

If a US chipbreaker is used for the inner and outer edges, the original cutting performance may not be exhibited.

The selection of insert grade is the same as for steel.

・For hardened steel and chipping measures,

select the UH breaker for the inner edge breaker.

The high-strength hard negative, wide land cutting edge, and tough PVD-coated carbide grade DP8020 make it ideal for machining hardened steel (45HRC or less) and preventing chipping of steel and cast iron.

・For aluminum alloy machining,

select the UN chipbreaker for both the inner and outer edges.

The top surface is polished and the periphery is polished to prevent welding, and the combination of positive land and strong rake angle creates a blade shape that emphasizes sharpness.

Features of grade

MC1020

MC1020 is a CVD-coated carbide grade suitable for external inserts with high cutting speeds.

While focusing on chipping prevention, it has improved plastic deformation resistance and is extremely excellent in cutting edge reliability.

MC5020

MC5020 is a CVD-coated carbide grade suitable for external inserts when drilling cast iron.

In addition to excellent wear resistance, it suppresses thermal cracks and chipping that tend to occur when machining ductile cast iron, achieving a long tool life.

VP15TF

VP15TF is a PVD coated carbide grade that offers great versatility in all materials.

The combination of ultra-fine cemented carbide base material and Miracle coating provides excellent adhesion resistance.

DP8020

DP8020 is a PVD-coated carbide grade suitable for machining hardened steel (45HRC or less) and chipping of steel and cast iron by combining a tough carbide base material and a hard Ti-Al-Si coating. .

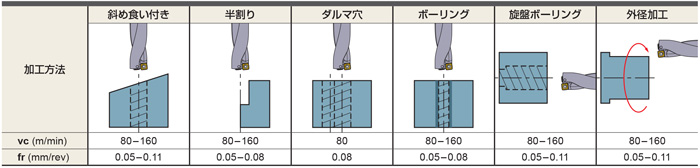

Examples of processing special holes

A holder of DCx4 or less is recommended for special processing.