GY Modular Blade

Caution

Product Description

[Features]

· A modular blade with a new concept shape.

· Reliable grooving achieved by a unique fastening system (tri-lock system).

· Various combinations of holders and inserts are available for various processing.

· Clamp method that opens up the possibility of grooving.

[Application]

· For outer diameter grooving.

- * Only modular blades are handled here. Please purchase the holder separately.

- * The reference sizes below are for when the holder is attached.

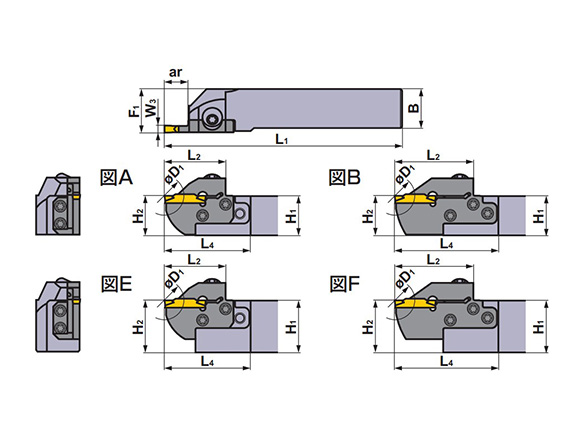

Grooving GY series (for outer diameter) Dimensional drawing of 00° straight holder 1 Grooving GY series (for outer diameter) Dimensional drawing of 00° straight holder 2

- * This drawing shows the right hand (R).

- * Set a right-hand (R) modular blade in a right-hand (R) holder, and a left-hand (L) modular blade in a left-hand (L) holder.

W3 = width of cut / ar = maximum grooving depth / D1 = maximum cut-off diameter

Features of this product

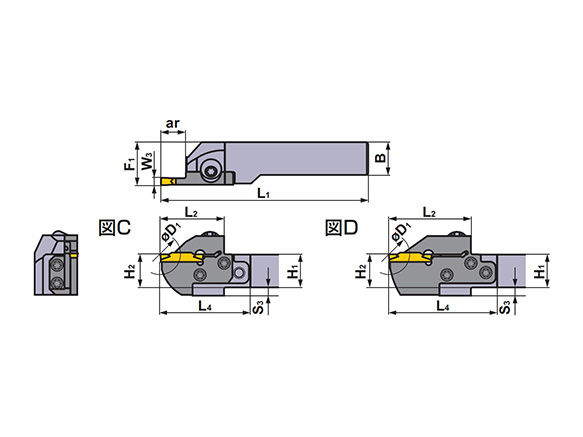

Modular type is just fit for various processing forms, groove widths and groove depths by selecting blades in the same holder. Abundant modular blades with different machining diameters, perfect fit for various end face machining diameters

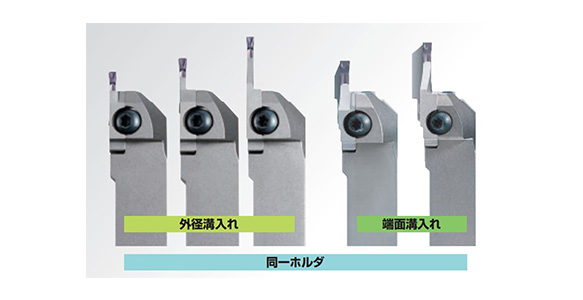

A highly reliable insert clamp that opens up the possibility of grooving

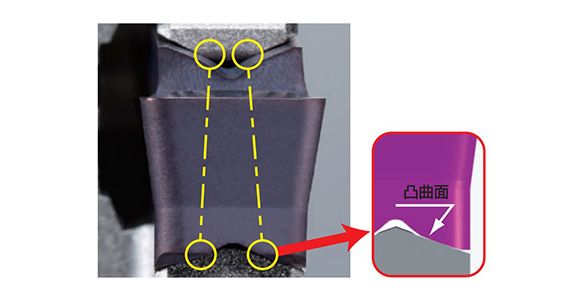

Safety key locks insert movement Highly accurate clamping due to convex curved surface support

Product comparison information

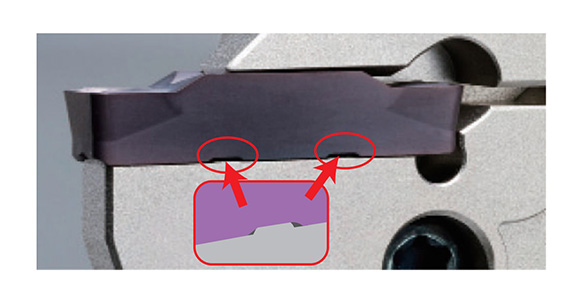

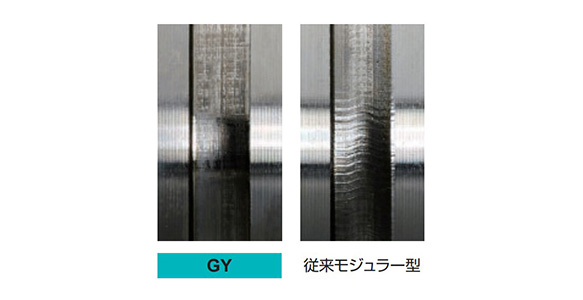

Elimination of chattering and blurring improves the grade of finished surface roughness.

cutting conditions

- Work material: SCM440

- Insert edge width: 5mm

- Cutting speed: 150m/min

- Feed: 0.2mm/rev

- Grooving depth: 23mm

Comparison of finished surface between GY series (left) and conventional modular type (right)

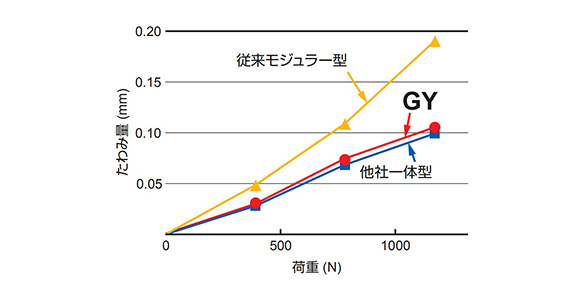

Rigidity comparison graph of the GY series, the conventional modular type, and the integrated type of other companies The GY series achieves the same steel properties as integrated grooving tools (main body for 5mm)

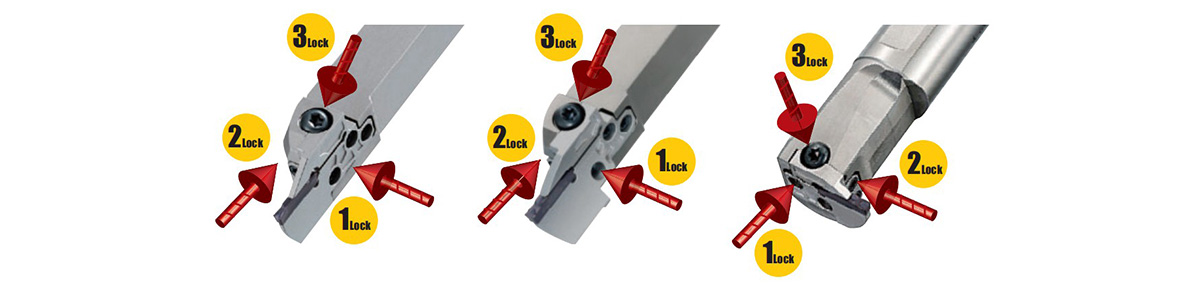

TRI-LOCK system

Firmly locked from 3 directions: side, front and top. High-rigidity clamp realizes stable machining

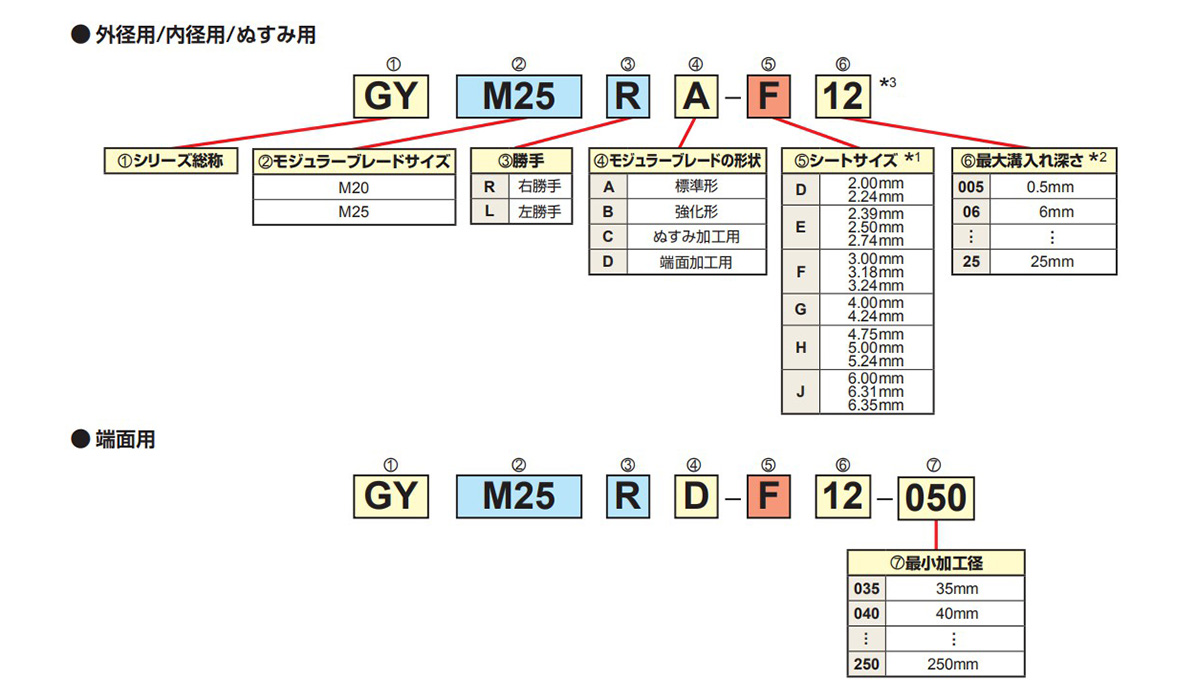

GY series order number (modular blade)

Order number of modular blades (for outer diameter, inner diameter, relief/end face)

- *1 Select the one with the same code as the sheet size code of the insert.

- *2 The maximum grooving depth shown is the value when used for external machining, and varies depending on the insert used. Please refer to the catalog when using for internal diameter machining.

- *3 GYM20R/LA-○10, GYM20R/LA-○12, GYM25R/LA-○12, GYM25R/LA-○14 can be used for both outer diameter and inner diameter.