SUMICON 1600 Series Multi-Contact Rectangular Connector

Caution

Product Description

A rectangular multi-contact connector manufactured using a unique HIROSE design.

[Features]

· Nine contact configurations (8, 12, 16, 20, 24, 28, 34, 45, 60) are available. Solder type, wrapping type and crimp type connector units are available.

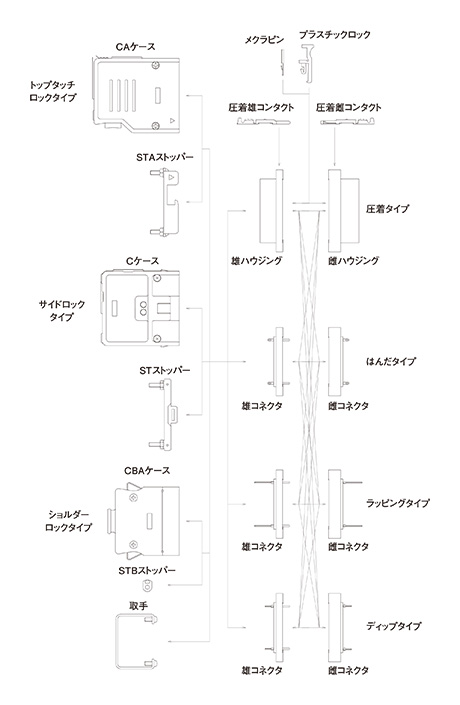

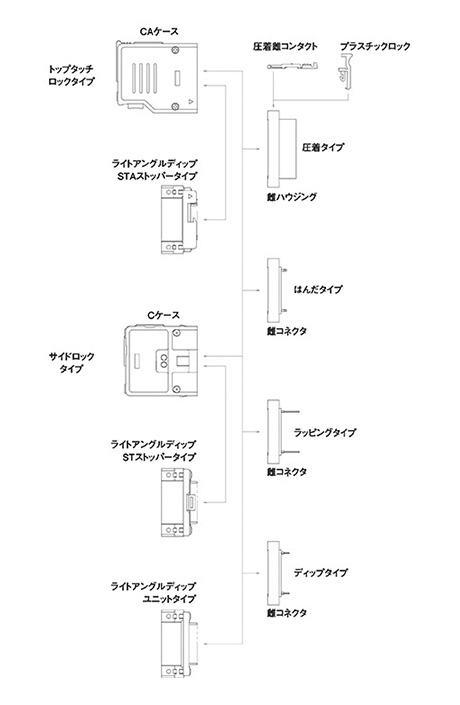

· Accessories include C case, CA case, CBA case, ST stopper, STA stopper, STB stopper, etc. that can be combined for use in a wide range of applications.

· The connector unit and accessories (cases, stoppers) are completely separate in the SUMICON 1600 series. This means that they can be combined for a variety of uses as well as enabling easier wiring connections.

· These connectors are specified in the NTT specifications, “Spec. No. 1931.”

1600 Series

SUMICON 1600 Series list

SUMICON 1600 Series crimp type

SUMICON 1600 Series DIP type

SUMICON 1600 Series right-angle DIP type (male)

Main Specifications of SUMICON 1600 Series Multi-Contact Rectangular Connectors

| Item | Standard Value |

|---|---|

| Operating Temperature Range | -55 to +85°C |

| Rated Current | 3 A |

| Rated voltage | 300 V AC |

| Contact resistance | 7 mΩ or less at 1 A DC |

| Insulation resistance | 1,000 MΩ or more at 500 V DC |

| Withstand Voltage | 1,000 V AC for 1 minute |

SUMICON 1600 Series product standards

| Part Name | Materials | Color/Finish |

|---|---|---|

| Insulator | Glass filled diallylphthalate resin | Blue |

| Male contact | Brass | Type A: silver plating |

| Female contacts | Phosphor bronze | Type G: gold plating |

| Plug case | ABS resin (black) | NTT specification is ABS resin 2.5PB 6.0/2.0 color |

| Stopper bracket | Steel | Nickel plating |

SUMICON 1600 Series materials/processing

| Part Name | Materials | Color/Finish |

|---|---|---|

| Plug case | Polypropylene resin | Black |

| Stopper | Steel | Nickel plating |

Shoulder-touch lock type materials/processing

| Compatible wire | AWG# | 26 | 28 | 30 |

| Wire diameter (mm) | 0.41 | 0.32 | 0.26 | |

| Maximum coating outer diameter (mm) | 0.95 | 0.75 | 0.6 | |

| Wrapping method | Ordinary wrapping | Coating one wrap | Coating one wrap | |

| Effective number of wrappings | Approx. 8 | Approx. 8 | Approx. 9 | |

| Number of wrappings per terminal | Two wraps | |||

SUMICON 1600 Series wrapping specifications

| Item | Standard Value | |||

|---|---|---|---|---|

| Operating Temperature Range | -55 to +85°C | |||

| Rated Current | 3 A | |||

| Rated voltage | 300 V AC | |||

| Contact resistance | 7 mΩ or less at 1 A DC (contact only) | |||

| Insulation resistance | 5,000 MΩ or more at 500 V DC | |||

| Withstand Voltage | 1,000 V AC for 1 minute | |||

| Compatible cable | AWG#24 to 28 (coating outer diameter ø0.9 to ø1.6) | |||

| Crimping strength (Units: kg or more) | Cable | AWG#24 | AWG#26 | AWG#28 |

| Crimping force | 3.6 | 2.4 | 1.6 | |

SUMICON 1600 Series crimp type product standards

| Part Name | Materials | Color/Finish |

|---|---|---|

| Insulator | Glass filled polycarbonate resin UL94V-0 | Blue |

| Male contact | Brass | Gold plating Silver plating |

| Female contacts | Phosphor bronze | Gold plating Silver plating |

SUMICON 1600 Series crimp type materials/processing

| Item | Standard Value |

|---|---|

| Operating Temperature Range | -55 to +85°C |

| Rated Current | 3 A |

| Rated voltage | 300 V AC |

| Contact resistance | 7 mΩ or less at 1 A DC |

| Insulation resistance | 1,000 MΩ or more at 500 V DC |

| Withstand Voltage | 1,000 V AC for 1 minute |

SUMICON 1600 Series DIP type product standards

| Part Name | Materials | Color/Finish |

|---|---|---|

| Insulator | Glass filled diallylphthalate resin (blue) | |

| Male contact | Brass | Type A: silver plating |

| Female contacts | Phosphor bronze | Type G: gold plating |

SUMICON 1600 Series DIP type materials/processing

| Item | Standard Value |

|---|---|

| Operating Temperature Range | -55 to +85°C |

| Rated Current | 3 A |

| Rated voltage | 300 V AC |

| Contact resistance | 10 mΩ or less at 1 A DC |

| Insulation resistance | 1,000 MΩ or more at 500 V DC |

| Withstand Voltage | 1 min. at 1,000 V AC r.m.s |

SUMICON 1600 Series right-angle DIP type (male) product standards

| Part Name | Materials | Color/Finish |

|---|---|---|

| Insulator | Glass filled diallylphthalate resin | Blue |

| Contacts | Brass | Type A: silver plating Type G: gold plating |

| Right-angle | Polybutylene terephthalate resin | Blue (UL94V-0) |

| Stopper bracket | Copper | Nickel plating |

SUMICON 1600 Series right-angle DIP type (male) materials/processing

| Classification | NTT No. | Short Form | Product No. | HRS No. |

|---|---|---|---|---|

| Plug | CN-3320GLWPMSA connector | 20GLWPMSA | P-1620BA-CA(01) | 216-0247-5 01 |

| CN-4028GLWPMSA connector | 28GLWPMSA | P-1628BA-CA(01) | 216-0249-0 01 | |

| CN-4534GLWPMSA connector | 34GLWPMSA | P-1634BA-CA(01) | 216-0250-0 01 | |

| CN-5445GLWPMSA connector | 45GLWPMSA | P-1645BA-CA(01) | 216-0251-2 01 | |

| CN-6760GLWPMSA connector | 60GLWPMSA | P-1660BA-CA(01) | 216-0252-5 01 | |

| CN-3320GLWPFSA connector | 20GLWPFSA | S-1620A-CA(01) | 216-0153-3 01 | |

| CN-3724GLWPFSA connector | 24GLWPFSA | S-1624A-CA(01) | 216-0154-6 01 | |

| CN-4028GLWPFSA connector | 28GLWPFSA | S-1628A-CA(01) | 216-0155-9 01 | |

| CN-4534GLWPFSA connector | 34GLWPFSA | S-1634A-CA(01) | 216-0126-0 01 | |

| CN-5445GLWPFSA connector | 45GLWPFSA | S-1645A-CA(01) | 216-0127-3 01 | |

| CN-6760GLWPFSA connector | 60GLWPFSA | S-1660A-CA(01) | 216-0128-6 01 | |

| Receptacle | CN-3724GJMSA connector | 24GJMSA | P-1624BA-STA(01) | 216-0254-0 01 |

| CN-4028GJMSA connector | 28GJMSA | P-1628BA-STA(01) | 216-0255-3 01 | |

| CN-4534GJMSA connector | 34GJMSA | P-1634BA-STA(01) | 216-0256-6 01 | |

| CN-5445GJMSA connector | 45GJMSA | P-1645BA-STA(01) | 216-0257-9 01 | |

| CN-6760GJMSA connector | 60GJMSA | P-1660BA-STA(01) | 216-0258-1 01 | |

| CN-3320G2JMSA connector | 20G2JMSA | PW-1620BA-STA(01) | 216-0292-0 01 | |

| CN-3724G2JMSA connector | 24G2JMSA | PW-1624BA-STA(01) | 216-0293-2 01 | |

| CN-4028G2JMSA connector | 28G2JMSA | PW-1628BA-STA(01) | 216-0294-5 01 | |

| CN-4534G2JMSA connector | 34G2JMSA | PW-1634BA-STA(01) | 216-0296-0 01 | |

| CN-6760G2JMSA connector | 60G2JMSA | PW-1660BA-STA(01) | 216-0298-6 01 | |

| CN-3320GJFSA connector | 20GJFSA | S-1620A-STA(01) | 216-0151-8 01 | |

| CN-3724GJFSA connector | 24GJFSA | S-1624A-STA(01) | 216-0148-3 01 | |

| CN-4028GJFSA connector | 28GJFSA | S-1628A-STA(01) | 216-0152-0 01 | |

| CN-4028G2JFSA connector | 28G2JFSA | SW-1628A-STA(01) | 216-0313-8 01 | |

| CN-4534G2JFSA connector | 34G2JFSA | SW-1634A-STA(01) | 216-0299-9 01 | |

| CN-5445G2JFSA connector | 45G2JFSA | SW-1645A-STA(01) | 216-0300-6 01 | |

| CN-6760G2JFSA connector | 60G2JFSA | SW-1660A-STA(01) | 216-0301-9 01 |

Cross reference to NTT No.

(Note) All NTT types include connector units. The items shown on each page are cases or stoppers only.

Function Diagram

Function diagram 1

Function diagram 2

Connector Mounting Hole Drilling Diagram

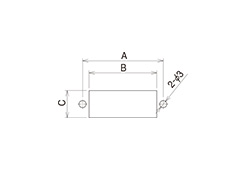

SUMICON 1600 Series crimp type connector mounting hole drilling diagram

Units: mm

| Number of Contacts | A | B | C | Compatible screw |

|---|---|---|---|---|

| 8 | 19 | 13.5 | 8.5 | M2.6 |

| 12 | 24 | 18.5 | 8.5 | |

| 16 | 29 | 23.5 | 8.5 | |

| 20 | 27 | 21.5 | 11.5 | |

| 24 | 31 | 25.5 | 11.5 | |

| 28 | 34 | 28.5 | 11.5 | |

| 34 | 39 | 33.5 | 11.5 | |

| 45 | 48 | 42.5 | 11.5 | |

| 60 | 61 | 55.5 | 11.5 |

SUMICON 1600 Series crimp type connector mounting hole drilling dimensions

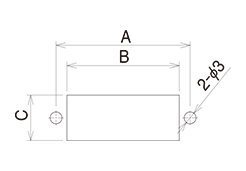

SUMICON 1600 Series DIP type mounting hole drilling diagram

Units: mm

| Number of Contacts | A | B | C | Compatible screw |

|---|---|---|---|---|

| 8 | 19 | 13.5 | 8.5 | M2.6 |

| 12 | 24 | 18.5 | ||

| 16 | 29 | 23.5 | ||

| 20 | 27 | 21.5 | 11.5 | |

| 24 | 31 | 25.5 | ||

| 28 | 34 | 28.5 | ||

| 34 | 39 | 33.5 | ||

| 45 | 45 | 42.5 | ||

| 60 | 61 | 55.5 |

SUMICON 1600 Series DIP type mounting hole drilling dimensions

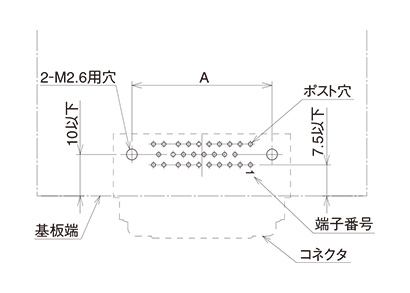

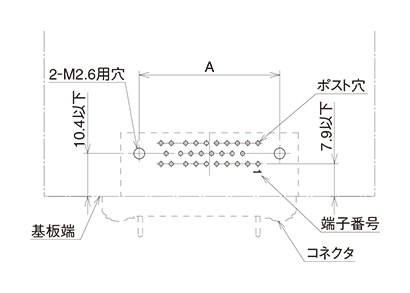

Connector Mounting Hole Drilling Diagram (SUMICON 1600 Series Right-Angle DIP Type [Male])

If inserting and soldering to a printed circuit board, drill mounting holes as shown below.

With top-touch lock type stopper bracket

With side-touch lock type stopper bracket

Product Usage

SUMICON 1600 Series Crimp Type Connector Usage

- 1. Take care when removing the connectors to pull out by the housing and not tug on the wires.

- 2. The male terminals of the connectors will be bent if the connectors are twisted when being removed. Take care to pull the characters out straight.

- 3. The plastic locks are sufficiently strong to ensure that the connector engagement will not be loosened by vibration or the weight of the wires. Their strength is not sufficient for other loads. When strength for some other load is required, use the top-touch lock type plug case (common for both solder and wrapping types.)

- 4. Both gold-plated and silver-plated terminals are available. Use the gold-plated type in adverse environments. In other environments the manufacturer recommends the economical silver-plated type.

- 5. Use a manual crimping device for low-volume crimping and maintenance. For high-volume crimping the manufacturer recommends their automatic crimping machine.

- 6. For plug-in uses, the manufacturer recommends the Sumicon 1600 Series solder or wrapping types for improved functionality.

SUMICON 1600 Series DIP Type Connector Usage

- 1. The male terminals of the connectors will be bent if the connectors are twisted when being removed. Take care to pull the characters out straight.

- 2. Both gold-plated and silver-plated terminals are available. Use the gold-plated type in adverse environments. In other environments the manufacturer recommends the economical silver-plated type.