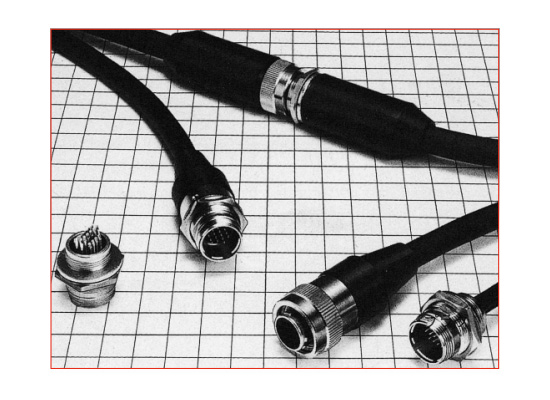

Miniature High Performance Circular Connector, HR22 Series

Caution

Product Description

Multi-pin, circular connectors with a vibration-resistant screw coupling structure (equipped with a spring for preventing looseness inside the coupling).

[Features]

· Waterproof and non-waterproof types are available, both of which can be interchanged as needed.

· The waterproof performance when mated is equivalent to IP67 and IP68.

· A crimping type and soldering type are available, allowing you to select depending on the application.

· The receptacle is easy to mount on panels with a front-tightening nut.

· The laboratory jack connector can be used as a panel jack.

· The shell is covered with a cable bushing and the bend radius has been increased to prevent disconnections when bent.

· Despite having 20 contacts, the plug features a highly dense design in which its maximum outer diameter is just 21 mm.

[Applications]

· Convenient for various types of wiring.

Miniature High-Performance Circular Connector

HR22 Series list

Specifications of HR22 Series High-Density Multi-Contact Circular Connector

Product Standards

| Rating | Rated Current | 2 A | Operating Temperature Range | -25 to +85°C |

|---|---|---|---|---|

| Rated voltage | 100 V AC, 140 V DC | Storage temperature range | -10 to +60°C |

| Item | Standard | Conditions |

|---|---|---|

| 1. Contact resistance | 20 mΩ or less | Measure at 1 A DC |

| 2. Insulation resistance: | 1,000 MΩ or more | Measure at 100 V DC |

| 3. Withstand voltage | There shall be no flashover or dielectric breakdown | 300 V AC for 1 min. |

| 4. Vibration resistance | There shall be no electrical discontinuity for 10 μs or greater | Test at 10 to 500 Hz/cycle, amplitude: 0.75 mm, acceleration: 98 m/s2 , three directions, 2 hours each. |

| 5. Shock | There shall be no electrical discontinuity for 10 μs or greater | Test at acceleration 490 m/s2, duration: 11 ms, 3 directions, 3 times each. |

| 6. Mating cycle | Contact resistance: 20 mΩ or less | 100 times |

| 7. Water pressure resistance | No water penetration inside connector. | Leave at water depth of 1.8 m for 48 hours while mated. |

Materials

| Item | Materials | Finish | Note |

|---|---|---|---|

| Outer shell | Brass | Nickel plating | - |

| Zinc diecast | - | ||

| Insulator | PBT resin | Black | UL94V-0 |

| Male contact | Brass (soldering) | Silver plating | - |

| Phosphor bronze (crimping) | - | ||

| Female contacts | Beryllium copper (soldering) | - | |

| Phosphor bronze (crimping) | - | ||

| Hood and bushing | Nitrile rubber | Black | - |

Product Usage

Applicable Tools

| Type | Product No. | HRS No. | Compatible Contact | Compatible Cable, Compatible Cable Diameter | |

|---|---|---|---|---|---|

| Manual crimping tools | HR22-TA2428HC | 150-0200-4 00 | HR22-PC-122 HR22-SC-122 | AWG#24 to 28 Coating outer diameter ø1.15 max. | |

| Automatic crimping tool | Crimping machine main body | CM-105C | 901-0001-0 00 | ‐ | - |

| Applicator | AP105-HR22-2 | 901-2023-7 00 | HR22-PC-222 HR22-SC-222 | AWG#24 to 28 Coating outer diameter ø1.15 max. | |

| Cable crimping tool | HR10A-TC-04 | 150-0058-5 00 | - | ø8.5 | |

| Crimping contact extraction tool | RP6-SC-TP | 150-0039-0 00 | - | - | |

| Cable termination tool | HR22-12P-T01 | 150-0075-4 00 | - | For plug connector | |

Manual crimping tool

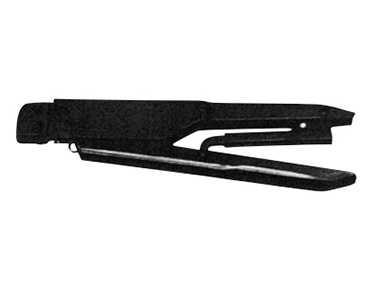

Extraction tool

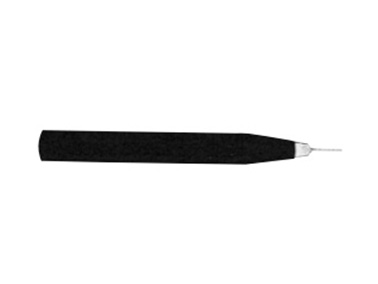

Cable crimping tool

(one example of handle shape is shown)

HR22-12P-T01

Automatic crimping machine CM-105C

Product Usage Precautions

- 1. Make sure the power is off before mating or un-mating the connector.

- 2. Because the power supply side of the circuit features a shock prevention function, be sure to use the connector female contact side.

- 3. Make sure that the coupling is in the completely locked position (fully tightened state.)

- 4.Cable clamping, cable rotation, and other forces may vary with the cable construction. Make sure that your cable is suitable for use with these connectors before usage and production.

- 5. This product uses silver plated contacts. Note that silver easily reacts to sulfur based gases, causing discoloration or degradation when exposed to certain environmental conditions such as those detailed below.

- Areas with high levels of powder dust and dirt

- Regions or areas with high concentrations of sulfur dioxide gas, hydrogen sulfide gas, nitrogen dioxide gas, etc. (Emission gases from vehicles and factories, etc.)

- Highly fluctuating temperatures, such as close to heating apparatus

It is recommended to store the products in their original packaging or similar state in order to prevent discoloration.

- Temperature: -10 to 60°C, humidity: 85% or less (An environment where temperature and relative humidity are constant and there is little temperature variation is recommended.)

- Use within 6 months of delivery. (If the storage period has expired, please examine the connectors and solder cups for corrosion and/or tarnish.)