Vacuum Unit, Ejector System ZK2 Series

Caution

- CAD data is not available for some models.

- The product images are representative images only. Please refer to the manufacturer's catalog for shape details.

Product Description

A vacuum unit ejector system manufactured by SMC

[Features]

· Built-in digital pressure switch for vacuums, with energy-saving function. Cuts the air supply upon reaching vacuum: Leading to 90% reduction in air consumption

· Has a 2-stage ejector structure that increases suction flow rate by 50% and reduces air consumption by 30% (compared to SMC's single-stage ejectors)

· Compact and lightweight, with a 28% reduction in volume (88 cm3) and a 59% reduction in weight (81 g) compared to conventional products

· Reduced wiring for single units as well as manifolding.

· Once the supply valve is switched ON, the vacuum generation state is maintained even if the power is cut off. This reduces power consumption.

Vacuum Unit, Ejector System ZK2 Series Specifications

Ejector external appearance

- Vacuum switch: pressure sensor, vacuum pressure switch, with energy-saving function, vacuum pressure switch, without vacuum switch

- Nozzle diameter: 0.7 mm, 1 mm, 1.2 mm, 1.5 mm

- Air pressure supply (PV) port: ø6 mm, ø1/4" one-touch fittings

- Vacuum (V) port: ø6 mm, ø8 mm one-touch fittings, ø1/4", ø5/16" one-touch fittings

- Supply and release valve rated voltage: 12, 24 V DC

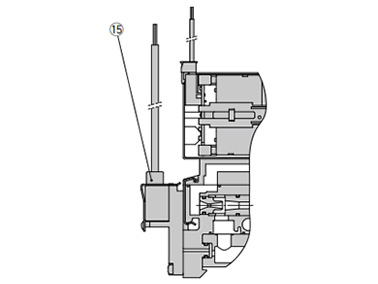

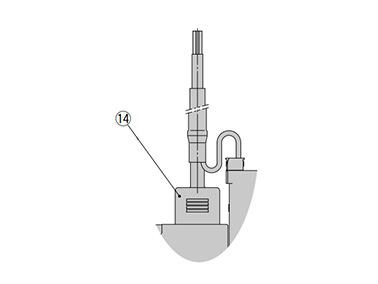

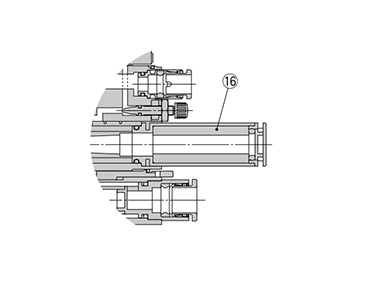

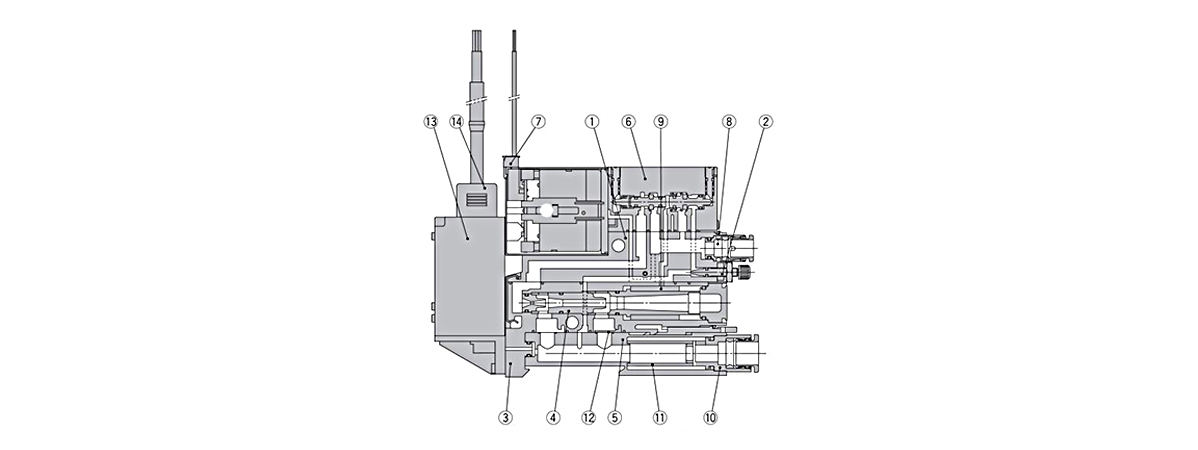

Structural Drawing

With pressure sensor

Lead wire with connector for switch with energy-saving function

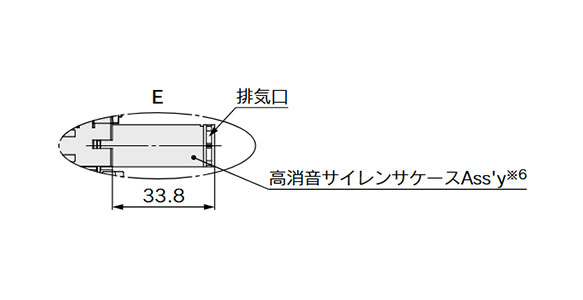

With high noise reduction silencer

With vacuum pressure switch

Components

| Number | Part Name | Main Materials | Note |

|---|---|---|---|

| 1 | Valve Body Assembly | Resin | If not resin, HNBR, NBR, steel, etc. are also used |

| 2 | Needle Assembly | Brass | If not electroless nickel plating or brass, resin, steel and NBR are also used |

| 3 | Ejector Body Assembly | Resin | If not resin, HNBR, NBR, steel, etc. are also used |

| 4 | Ejector Assembly | Resin | If not resin, NBR is used |

| 5 | Filter Case Assembly | Resin | Case body: polycarbonate |

Replacement Parts

| Number | Part Name | Note |

|---|---|---|

| 6 | Valve Assembly | - |

| 7 | Connector Assembly | Solenoid valve connector 3-wire (for double), 2-wire (for single) |

| 8 | One-Touch Fitting Assembly | Supply (PV) port standards are ø6 mm and ø1/4" |

| 9 | Sound-Absorbing Material | 10 pieces per set |

| 10 | Vacuum Port Adapter Assembly | With one-touch fitting and filter element (case material: polycarbonate) |

| 11 | Filter Element | Filtration degree: 30 μm, 10 pieces per set |

| 12 | Check Valve | For replacement or additions to prevent manifold exhaust interference, 10 pieces per set |

| 13 | Vacuum Pressure Switch Assembly | With 2 screws, 1 gasket |

| 14 | Lead wire with connector | - |

| 15 | Pressure Sensor Assembly | With 2 screws, 1 gasket |

| 16 | High Noise Reduction Silencer Case Assembly | With sound-absorbing material (part no.: ZK2-SE4-6-A) |

Drawing / Single Unit

With high noise reduction silencer exhaust

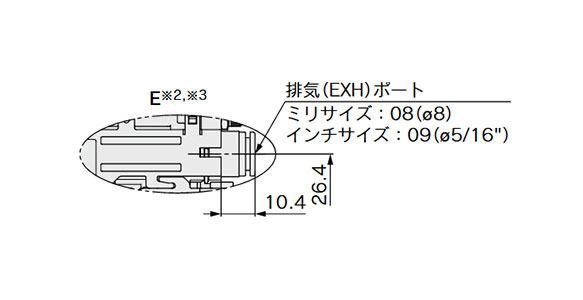

With port exhaust

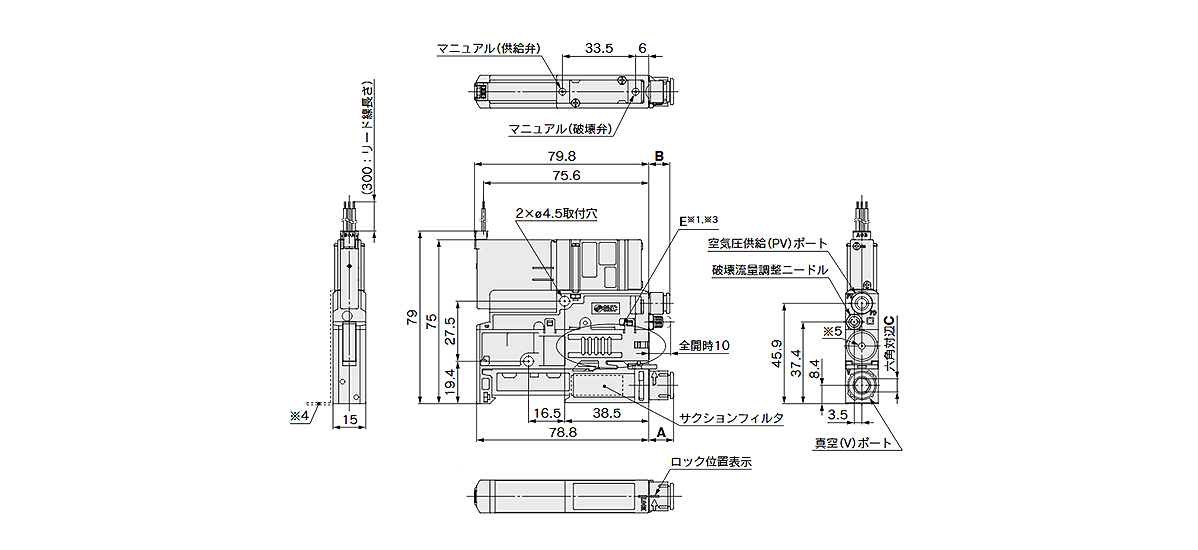

Ejector System, Single Unit, With Supply Valve / Release Valve, Without Switch / Pressure Sensor

(Unit: mm)

ZK2(A, B, G)□(K, R)□NL2-□ dimensional drawing

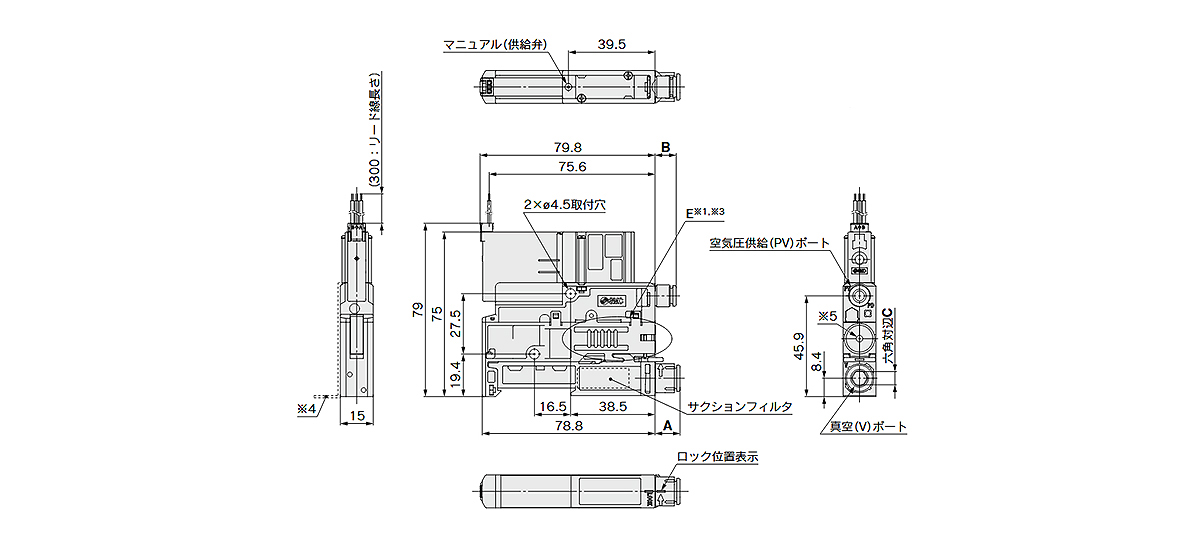

Ejector System, Single Unit, With Supply Valve, Without Switch / Pressure Sensor

(Unit: mm)

ZK2(A, B, G)□J□NL2-□ dimensional drawing

- *1 For the silencer exhaust type, air is exhausted from the slits on both sides. (Do not cover both sides. Leave at least one side open for release.)

- *2 For the port exhaust type, air is exhausted from the one-touch fitting.

- *3 Pilot pressure exhaust is shared with ejector exhaust.

- *4 See the manufacturer's catalog for dimensions with the bracket mounted.

- *5 Nozzles with a diameter of 12 and 15 have an exhaust port.

- *6 See the manufacturer's catalog for information regarding high noise reduction silencer case assembly part numbers and maintenance.

| PV Port Type | B | ||

|---|---|---|---|

| Metric Size | 06 | ø6 mm | 9.7 |

| Inch Size | 07 | ø1/4" | 12.3 |

| V Port Type | A | C | ||

|---|---|---|---|---|

| Metric Size | 06 | ø6 mm | 8.25 | 4 |

| 08 | ø8 mm | 11.4 | 6 | |

| Inch Size | 07 | ø1/4" | 10.8 | 4.76 |

| 09 | ø5/16" | 11.4 | 6 | |

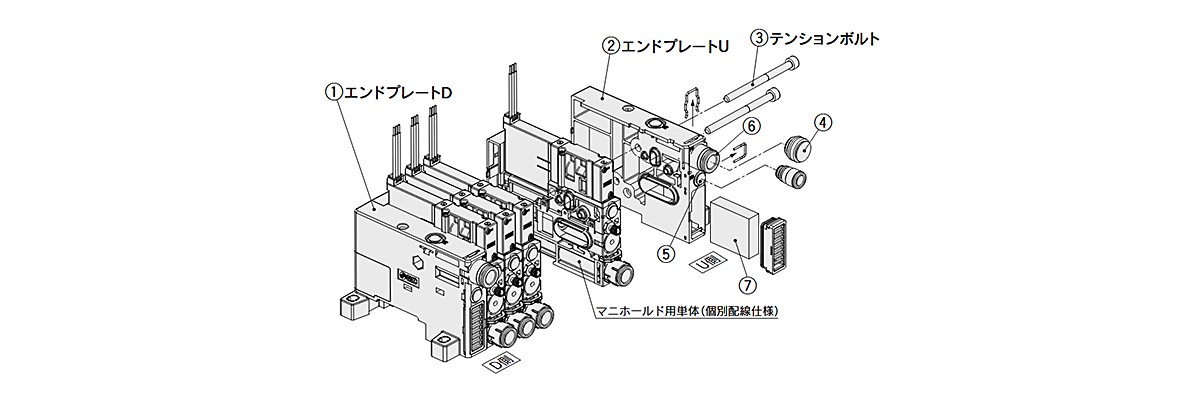

Vacuum Unit ZK2 Series Manifold Structure

Exploded view of manifold

Components

| Number | Part Name | Main Materials | Note |

|---|---|---|---|

| 1 | End Plate D Assembly | Resin | If not resin, HNBR, NBR, steel, etc. are also used |

| 2 | End Plate U Assembly | Resin | If not electroless nickel plating or brass, resin, steel and NBR are also used |

Replacement Parts

| Number | Part Name | Note |

|---|---|---|

| 3 | Tension Bolt Assembly | 2 pieces per set |

| 4 | Port Plug Assembly | Plug for changing PV port to single side supply specification. (Common for both metric and inches) |

| 5 | Port Plug Assembly | Plug for changing PS and PD ports to single side supply specifications. (Common for both metric and inches) |

| 6 | One-Touch Fitting Assembly | Metric size: ø8 mm, Inch size: ø5/16" |

| 7 | Sound-Absorbing Material | 2 pieces per set, Material: non-woven fabric (silencer cover not included) |

| 8 | DIN Rail | For the recommended length for each manifold station, refer to the drawing. |

| 9 | Connector Housing Assembly | Even number of stations only (if a connector for odd numbers is required, specify the connector number required plus 1 station) |

Increasing Manifold Stations (Individual Wiring Specifications)

- 1. Remove the tension bolts (2 pcs.)

- 2. Remove the end plate U (take care not to drop the gasket).

- 3. Mount a single unit for extra station(s) for manifolds to the end surface of the U side. (Do not let the gasket get caught)

- 4. Mount the end plate U with the appropriate tension bolts for the given number of stations. (Tightening torque: 0.75 N·m)

Notes

- *Refer to the manufacturer's catalog for product information not detailed above.

- The product images are representative images only.