Male Elbow KPL Clean One-Touch Fitting

Caution

- The minimum order quantity varies depending on the selected model. Please check the quotation / order screen for details.

- *See the catalog for detailed specs and materials.

- Product images may be representative images. Refer to the catalog for details.

Product Description

A one-touch coupling from SMC Corporation.

[Features]

· A one-touch fitting; ideal for blowing type systems in clean rooms.

· Completely oil-free processing. (rubber parts are fluorine coated)

· Liquid-contact areas are non-metallic.

· Parts are cleaned, assembled and double packaged in a clean room.

· Can also be used in vacuums. (-100 kPa)

[Applications]

· Use to connect piping in a perpendicular orientation from female threads.

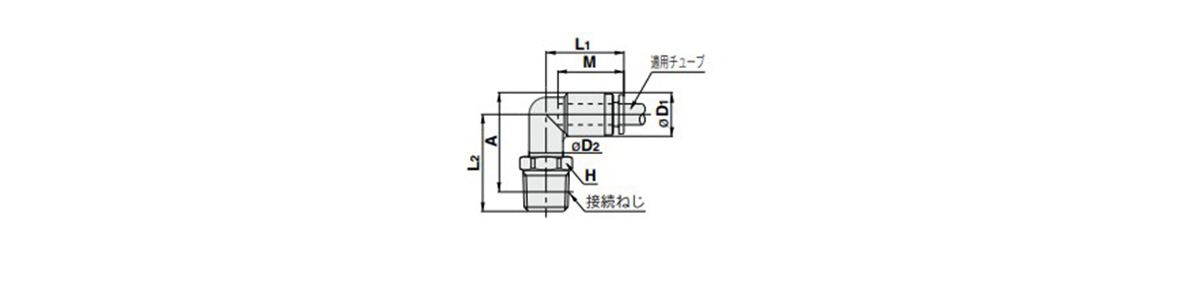

Male Elbow KPL Outline Drawing And Dimensions

Male Elbow KPL outline drawing

| Applicable tube outer diameter mm | Connection thread R | Model | H (width across flats) | Note 1: øD1 | øD2 | L1 | L2 | *A | M | Effective area mm2 | Weight g | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TPH | TPS | |||||||||||

| 4 | 1/8 | KPL04-01 | 12 | 10.4 | 10 | 19.7 | 23.2 | 24.5 | 17 | 3.5 | 3.5 | 4 |

| 1/4 | KPL04-02 | 14 | 27.2 | 26.5 | 5 | |||||||

| 6 | 1/8 | KPL06-01 | 12 | 12.8 | 21.8 | 24.4 | 27 | 18.5 | 9 | 9 | 5 | |

| 1/4 | KPL06-02 | 14 | 28.4 | 29 | 6 | |||||||

| 8 | 1/8 | KPL08-01 | 15.2 | 12 | 25.3 | 26.6 | 30 | 20.5 | 22 | 15 | 8 | |

| 1/4 | KPL08-02 | 29.4 | 31.5 | 9 | ||||||||

| 10 | 1/4 | KPL10-02 | 17 | 18.5 | 17 | 28.4 | 32.1 | 35.5 | 23 | 35 | 25 | 13 |

| 3/8 | KPL10-03 | 33.1 | 36.5 | 14 | ||||||||

| 12 | 3/8 | KPL12-03 | 20.9 | 30.4 | 34.3 | 38.5 | 24 | 50 | 40 | 15 | ||

| 1/2 | KPL12-04 | 22 | 22 | 38.3 | 41.5 | 18 | ||||||

*Reference dimensions after screwing in R thread

Note 1: øD1 indicates the maximum diameter.

Clean One-Touch Fitting For Blowing KP Series Common Specifications (Reference)

Applicable Tube

| Tube materials | PFA, polyolefin Soft polyolefin, polyurethane |

|---|---|

| Tube outer diameter | ø4, ø6, ø8, ø10, ø12 |

Note 1: FEP, nylon, soft nylon and other non-clean specification tubes can be used, but performance in terms of cleanliness will be reduced.

Note 2: Because polyurethane is a soft material, the tube may break when inserting. Hold the tube at its base and insert securely so that it reaches the back.

Specifications

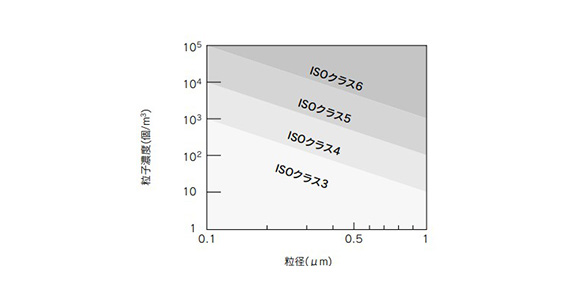

| Cleanliness class (ISO class) | Class 3 Note 1: |

|---|---|

| Usable fluids | Air, nitrogen gas, water, deionized water (pure water) Note 2: |

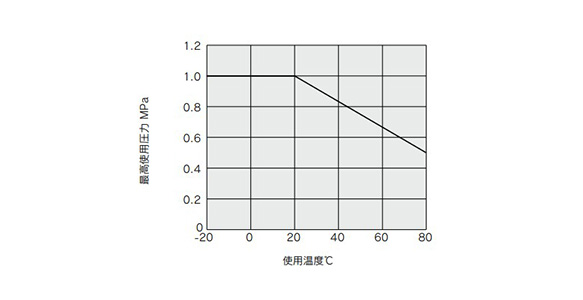

| Maximum operating pressure (20°C) | 1 MPa Note 3: |

| Operating vacuum pressure | -100 kPa {10 Torr} |

| Guaranteed proof pressure (20°C) | 3 MPa |

| Ambient temperature and working fluid temperature | -20°C to 80°C |

| Thread | JIS B0203 (tapered thread for pipes/tubes) |

Note 1: See the "Particle emissions grade classifications" below.

Note 2: Make sure the surge pressure stays below the maximum operating pressure.

Note 3: The maximum operating pressure is the value at 20°C. For other temperatures, see "Relationship between operating temperature and maximum operating pressure" below.

Note 4: It is not completely airtight, so please avoid use in leak testers, etc., where a vacuum is maintained.

Particle Emissions Grade Classifications

Particle emissions grade classifications graph

Relationship Between Operating Temperature And Maximum Operating Pressure

Operating temperature and maximum operating pressure graph

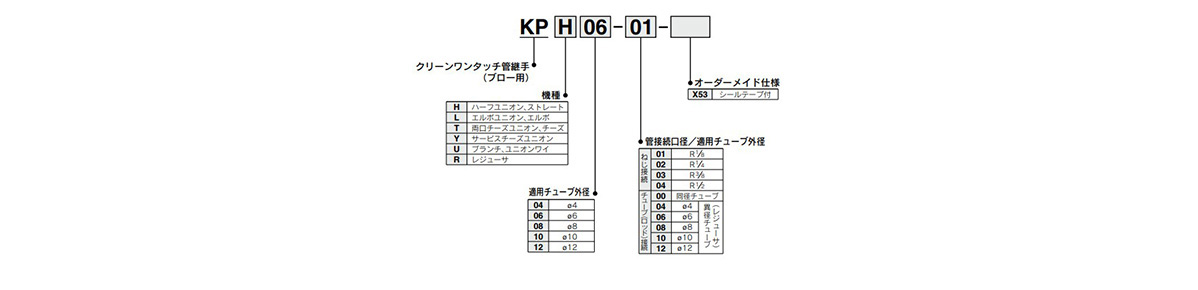

Model Indication Method

Clean One-Touch Fitting For Blowing KP Series model indication method

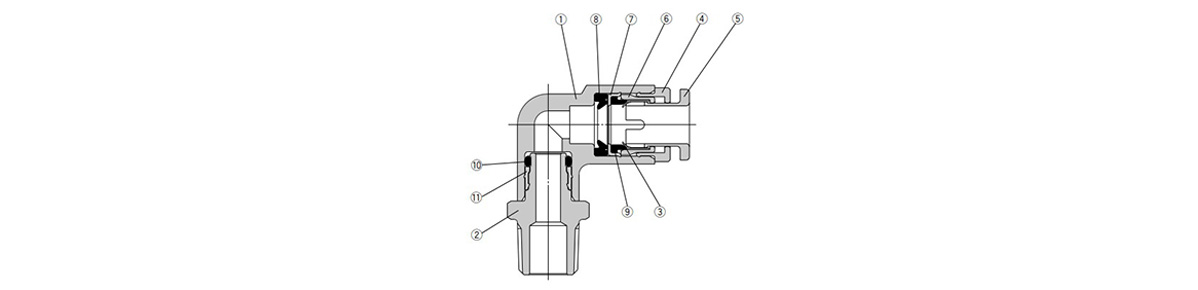

Structural Drawing And Components

Clean One-Touch Fitting For Blowing KP Series structural drawing

| Number | Part name | Materials |

|---|---|---|

| 1 | Body | PP |

| 2 | Stud | PP |

| 3 | Chuck | SUS304 |

| 4 | Guide | SUS304 |

| 5 | Release button | PP (Color: light green) |

| 6 | Collet | PP |

| 7 | Stopper | SUS304 |

| 8 | Seal | EPDM (fluorine coating) |

| 9 | Bumper | EPDM (fluorine coating) |

| 10 | O-ring | EPDM (fluorine coating) |

| 11 | Drive bushing | SUS304 |

Usage Precautions

- The KP Series is composed of dedicated one-touch fittings for clean blow and cleaning lines.

- Seal material used: Since the durability of EPDM degrades when exposed to mineral oils, it is not suitable for general pneumatic equipment piping.