Stainless steel helical gear

Brand :

KHK

Caution

Product Description

Stainless steel spiral gears are prone to wear and galling, so different combinations of materials are recommended.

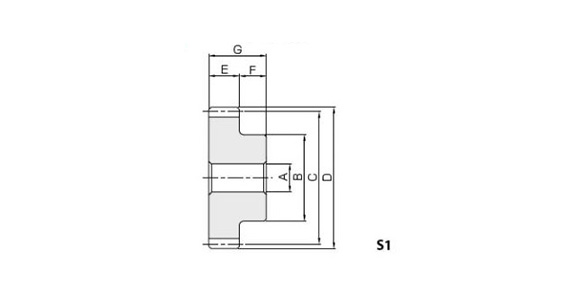

Drawing

Dimensional drawing

Product Specifications

External appearance

| Common Specifications | |||

|---|---|---|---|

| Accuracy Class | JIS B 1702-1 Class N9 (*1) | Materials | SUS303 |

| Gear reference cross section | Normal | Surface Treatment | None |

| Profile | Standard Gear | Tooth flank finish | Milled |

| Normal pressure angle | 20° | Gear cutting reference cross section | Hole (H7) |

| Helix angle | 45° | Alteration | Possible |

(*1) Former JIS B 1702 Class 5

Standard table

| Part number | Module | No. of teeth | Helix direction | Shape | Hole diameter A | Boss Diameter B | Reference diameter C | Tip diameter D | Tooth width E | Boss length F | Overall Length G | Allowable tooth flank strength (kgf ⋅ m) | Backlash Lower limit (mm) | Backlash Upper limit (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SUN1-13R | 1 | 13 | R | S1 | 6 | 15 | 18.38 | 20.38 | 10 | 10 | 20 | 0.019 | 0.08 | 0.18 | 0.030 |

| SUN1-13L | 1 | 13 | L | S1 | 6 | 15 | 18.38 | 20.38 | 10 | 10 | 20 | 0.019 | 0.08 | 0.18 | 0.030 |

| SUN1-15R | 1 | 15 | R | S1 | 6 | 18 | 21.21 | 23.21 | 10 | 10 | 20 | 0.029 | 0.08 | 0.18 | 0.043 |

| SUN1-15L | 1 | 15 | L | S1 | 6 | 18 | 21.21 | 23.21 | 10 | 10 | 20 | 0.029 | 0.08 | 0.18 | 0.043 |

| SUN1.5-10R | 1.5 | 10 | R | S1 | 8 | 16 | 21.21 | 24.21 | 15 | 10 | 25 | 0.029 | 0.08 | 0.20 | 0.047 |

| SUN1.5-10L | 1.5 | 10 | L | S1 | 8 | 16 | 21.21 | 24.21 | 15 | 10 | 25 | 0.029 | 0.08 | 0.20 | 0.047 |

| SUN1.5-13R | 1.5 | 13 | R | S1 | 10 | 23 | 27.58 | 30.58 | 15 | 10 | 25 | 0.063 | 0.10 | 0.22 | 0.087 |

| SUN1.5-13L | 1.5 | 13 | L | S1 | 10 | 23 | 27.58 | 30.58 | 15 | 10 | 25 | 0.063 | 0.10 | 0.22 | 0.087 |

| SUN1.5-15R | 1.5 | 15 | R | S1 | 10 | 25 | 31.82 | 34.82 | 15 | 10 | 25 | 0.095 | 0.10 | 0.22 | 0.12 |

| SUN1.5-15L | 1.5 | 15 | L | S1 | 10 | 25 | 31.82 | 34.82 | 15 | 10 | 25 | 0.095 | 0.10 | 0.22 | 0.12 |

| SUN1.5-20R | 1.5 | 20 | R | S1 | 12 | 30 | 42.43 | 45.43 | 15 | 10 | 25 | 0.22 | 0.10 | 0.22 | 0.20 |

| SUN1.5-20L | 1.5 | 20 | L | S1 | 12 | 30 | 42.43 | 45.43 | 15 | 10 | 25 | 0.22 | 0.10 | 0.22 | 0.20 |

| SUN2-10R | 2 | 10 | R | S1 | 12 | 22 | 28.28 | 32.28 | 20 | 15 | 35 | 0.068 | 0.10 | 0.22 | 0.11 |

| SUN2-10L | 2 | 10 | L | S1 | 12 | 22 | 28.28 | 32.28 | 20 | 15 | 35 | 0.068 | 0.10 | 0.22 | 0.11 |

| SUN2-13R | 2 | 13 | R | S1 | 12 | 30 | 36.77 | 40.77 | 20 | 15 | 35 | 0.14 | 0.12 | 0.26 | 0.22 |

| SUN2-13L | 2 | 13 | L | S1 | 12 | 30 | 36.77 | 40.77 | 20 | 15 | 35 | 0.14 | 0.12 | 0.26 | 0.22 |

| SUN2-15R | 2 | 15 | R | S1 | 12 | 35 | 42.43 | 46.43 | 20 | 15 | 35 | 0.22 | 0.12 | 0.26 | 0.30 |

| SUN2-15L | 2 | 15 | L | S1 | 12 | 35 | 42.43 | 46.43 | 20 | 15 | 35 | 0.22 | 0.12 | 0.26 | 0.30 |

| SUN2-20R | 2 | 20 | R | S1 | 15 | 45 | 56.57 | 60.57 | 20 | 15 | 35 | 0.49 | 0.12 | 0.26 | 0.53 |

| SUN2-20L | 2 | 20 | L | S1 | 15 | 45 | 56.57 | 60.57 | 20 | 15 | 35 | 0.49 | 0.12 | 0.26 | 0.53 |

| SUN2.5-10R | 2.5 | 10 | R | S1 | 12 | 26 | 35.36 | 40.36 | 22 | 16 | 38 | 0.13 | 0.12 | 0.24 | 0.20 |

| SUN2.5-10L | 2.5 | 10 | L | S1 | 12 | 26 | 35.36 | 40.36 | 22 | 16 | 38 | 0.13 | 0.12 | 0.24 | 0.20 |

| SUN2.5-13R | 2.5 | 13 | R | S1 | 15 | 35 | 45.96 | 50.96 | 22 | 16 | 38 | 0.27 | 0.14 | 0.28 | 0.35 |

| SUN2.5-13L | 2.5 | 13 | L | S1 | 15 | 35 | 45.96 | 50.96 | 22 | 16 | 38 | 0.27 | 0.14 | 0.28 | 0.35 |

| SUN2.5-15R | 2.5 | 15 | R | S1 | 15 | 40 | 53.03 | 58.03 | 22 | 16 | 38 | 0.41 | 0.14 | 0.28 | 0.48 |

| SUN2.5-15L | 2.5 | 15 | L | S1 | 15 | 40 | 53.03 | 58.03 | 22 | 16 | 38 | 0.41 | 0.14 | 0.28 | 0.48 |

| SUN2.5-20R | 2.5 | 20 | R | S1 | 20 | 60 | 70.71 | 75.71 | 22 | 16 | 38 | 0.92 | 0.14 | 0.28 | 0.93 |

| SUN2.5-20L | 2.5 | 20 | L | S1 | 20 | 60 | 70.71 | 75.71 | 22 | 16 | 38 | 0.92 | 0.14 | 0.28 | 0.93 |

| SUN3-10R | 3 | 10 | R | S1 | 15 | 34 | 42.43 | 48.43 | 25 | 18 | 43 | 0.22 | 0.12 | 0.26 | 0.34 |

| SUN3-10L | 3 | 10 | L | S1 | 15 | 34 | 42.43 | 48.43 | 25 | 18 | 43 | 0.22 | 0.12 | 0.26 | 0.34 |

| SUN3-13R | 3 | 13 | R | S1 | 20 | 45 | 55.15 | 61.15 | 25 | 18 | 43 | 0.46 | 0.14 | 0.32 | 0.58 |

| SUN3-13L | 3 | 13 | L | S1 | 20 | 45 | 55.15 | 61.15 | 25 | 18 | 43 | 0.46 | 0.14 | 0.32 | 0.58 |

| SUN3-15R | 3 | 15 | R | S1 | 20 | 50 | 63.64 | 69.64 | 25 | 18 | 43 | 0.69 | 0.14 | 0.32 | 0.79 |

| SUN3-15L | 3 | 15 | L | S1 | 20 | 50 | 63.64 | 69.64 | 25 | 18 | 43 | 0.69 | 0.14 | 0.32 | 0.79 |

| SUN3-20R | 3 | 20 | R | S1 | 20 | 60 | 84.85 | 90.85 | 25 | 18 | 43 | 1.53 | 0.14 | 0.32 | 1.39 |

| SUN3-20L | 3 | 20 | L | S1 | 20 | 60 | 84.85 | 90.85 | 25 | 18 | 43 | 1.53 | 0.14 | 0.32 | 1.39 |

Linking with dimensional drawings

Cautions/prohibitions

Cautions/prohibitions

- 1. Using the same material for screw gears may cause wear and galling, so the combination with other materials is recommendable.

- 2. The allowable torque shown above is a reference value calculated under arbitrary usage conditions. Please check the precautions for details.

- 3. The backlash shown above is the normal backlash when assembled with the same part number at theoretical value.

- 4. When using for skewed shafts (screw gears), it becomes a combination of helices in the identical direction (right and right or left and left), and when using for parallel shafts (helical gears), it becomes a combination of different helices (right and left).

- 5. The tolerance of ø4 or less hole diameter (diameter 4 mm) is H8. Also, if the hole diameter is ø5 (diameter 5 mm) or ø6 (diameter 6 mm) and the hole length (overall length) is more that 3 times the hole diameter, the tolerance is H8 as well.

Precautions for alteration

- 1. For alteration to screw gears, it is necessary to check "precautions for alteration" in the precautions for safety before alteration.

- 2. Please refrain from processing to narrow the tooth width because it will affect the accuracy and strength of the gear.