Cleanroom wiper 160g C100 - Polyester 9"x9" - Ultrasonic Cut Edge

Caution

Product Description

[New!] MISUMI Cleanroom Wiper ISO Class 5 (Class 100) – Polyester 9”x9”

Wipers are made from 100% continuous filament of 75 denier white yarn Polyester in double knitted interlock pattern. It can absorb liquids on contact with high abrasion resistant. Wipers provide cleanliness laundered with DI water filtered to 0.1 microns to ensure ultra low levels of particles, fibers, ions and extractable ion contamination. It is available with Ultrasonic cut edges to prevent particle generation. Wipers are packaged in ISO Class 5 (Class 100) Clean Room with double-bagged to maintain wipers cleanliness.

It is suitable for Clean Room, Electronics industry, Precision instrument manufacturing, Pharmaceutical industry and other industries.

[Description]

- Brand : MISUMI

- Material : 100% Polyester

- Size (inch) : 9x9 ±0.5 inch (228.6 mm±12.7 mm)

- Cleanroom class : 100

- ISO standard : ISO 14644-1 Class 5

- Fabric edge cutting : Ultrasonic Cut

- Basic weight (g/m^2) : 140 (+/-10)

- Color : White

- Packing type : Stack

- Package : Double-bagged (150 sheets/bag)

- Extremely low levels of particles and extractable

- Strong and durable fabric made of continuous filament, double knit Polyester

- Compatible with IPA, Acetone and other solvents

- Compatible with ISO Class 5 (Class 100) or higher cleanroom environments for the Most delicate surface wiping tasks

- Ultrasonic Cut edge to minimize lint generation

- Statistical quality control/ISO Quality Assurance

Product specification Cleanroom wiper

| Product code | Material | Size (inch) | Package (Stack) | Selling unit price per sheet |

|---|---|---|---|---|

| MW5-PE-99-S | 100% Polyester | 9X9 ±0.5 inch (228.6 mm±12.7 mm) | 150 sheet/bag (Double-bagged) | 4 baht |

It is suitable for Clean Room, Electronics industry, Precision instrument manufacturing, Pharmaceutical industry and other industries.

Reference information Cleanroom wiper

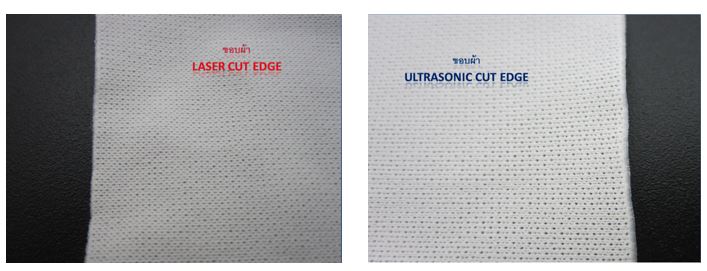

Comparative data on fabric edge cutting by Ultrasonic technology and Laser machines

| Characteristic of Cutting edge | Laser Cut | Ultrasonic Cut | Remark |

|---|---|---|---|

| Feasibility of Yellow Edge | / | X | Over-heat from Laser voltage adjustment |

| Hard edge | / | X | |

| Possible of Fiber come out from edge | / | X | Due to narrow seal edge |