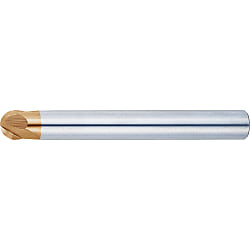

TS Coated Carbide Ball End Mill, Cutting Edge Rigidity Machining / For High-Hardness Steel Machining, 2-Flute / No Side Blade

Caution

Product Description

[Features]

·Ultra-fine particle cemented carbide base material suitable for machining high hardness steel is used (according to the manufacturer cutting test results).

·MISUMI original shape with cutting edge rigid treatment and no side cutting edge. High rigid tool and cutting edge strength, achieving stable cutting edge shape and long tool lifespan in high-speed milling

·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

Specifications

| Model Number | Flute Length ℓ | Outer Diameter D | Under Neck Diameter d1 | Length Under Neck ℓ1 | Overall Length L | Shank Diameter d | Figure | |

| Tip R | ||||||||

| TSC-CHBEM2N | 1 | 1 | 2 | 2 | 5 | 50 | 6 | 1 |

| 1.5 | 1.5 | 3 | 3 | 7.5 | 60 | 6 | 1 | |

| 2 | 2 | 4 | 4 | 10 | 60 | 6 | 1 | |

| 3 | 3 | 6 | - | - | 80 | 6 | 2 | |

| 5 | 5 | 10 | - | - | 90 | 10 | 2 |

For Cutting Conditions, Refer to >>Click here.

More Information

● It adopts a base material with super-ultra-fine particles suitable for high hardness steel machining (as per the results of cutting tests conducted by us).

● A Misumi original shape that has been treated for an extra rigid blade tip and does not have a side-surface cutting edge. High tool rigidity / blade tip hardness yields both a stable blade tip shape and long life when used for high speed milling machines.

● The TS coating consisting of a nitride-based composite film with a fully crystalline structure means that it yields a high oxidation resistance temperature and high hardness. It is ideal for high speed machining and dry machining of heat-treated / high hardness steel.

[ ! ]This product has a special shape with a performance that may not be reproducible without the use of Misumi's dedicated re-grinding.