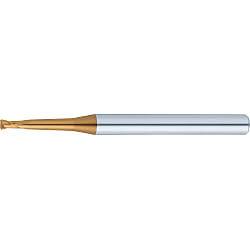

TSC series carbide tapered neck radius end mill, 2-flute / tapered neck model

Caution

Product Description

[Features]

·Suppresses chattering by adopting short flute length and back taper shape on peripheral edge

·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties

·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

Specifications

Model Number

TSC-REM2PB (Stocked Product)

| Outer Diameter D | Neck Gradient θ1 | Length Under Neck ℓ1 | Radius R | Under Neck Diameter d1 | Flute Length ℓ | Overall Length L | Shank Diameter d | Figure |

| 0.2 | 1° | 1 | 0.05 | 0.22 | 0.16 | 50 | 4 | 1 |

| 2 | 0.26 | |||||||

| 3° | 1 | 0.26 | ||||||

| 2 | 0.37 | |||||||

| 5° | 1 | 0.30 | ||||||

| 2 | 0.48 | |||||||

| 0.3 | 1° | 2 | 0.05 | 0.35 | 0.24 | 50 | 4 | 1 |

| 3 | 0.38 | |||||||

| 3° | 2 | 0.45 | ||||||

| 3 | 0.55 | |||||||

| 5° | 2 | 0.54 | ||||||

| 3 | 0.72 | |||||||

| 0.4 | 1° | 3 | 0.05 0.1 | 0.48 | 0.28 | 50 | 4 | 1 |

| 4 | 0.51 | |||||||

| 3° | 3 | 0.63 | ||||||

| 4 | 0.74 | |||||||

| 5° | 3 | 0.78 | ||||||

| 4 | 0.96 | |||||||

| 0.5 | 1° | 3 | 0.05 0.1 | 0.57 | 0.32 | 50 | 4 | 1 |

| 5 | 0.64 | |||||||

| 8 | 0.74 | |||||||

| 10 | 0.81 | |||||||

| 12 | 0.88 | |||||||

| 3° | 3 | 0.71 | ||||||

| 5 | 0.92 | |||||||

| 8 | 1.23 | |||||||

| 10 | 1.44 | |||||||

| 12 | 1.65 | |||||||

| 5° | 3 | 0.85 | ||||||

| 5 | 1.20 | |||||||

| 8 | 1.72 | |||||||

| 10 | 2.07 | |||||||

| 0.8 | 1° | 5 | 0.05 0.1 0.2 | 0.92 | 0.64 | 50 | 4 | 1 |

| 8 | 1.02 | |||||||

| 3° | 5 | 1.16 | ||||||

| 8 | 1.47 | |||||||

|

1 | 1° | 6 | 0.05 0.1 0.2 0.3 | 1.14 | 0.8 | 50 | 4 | 1 |

| 10 | 1.28 | |||||||

| 15 | 1.45 | |||||||

| 20 | 1.63 | 70 | ||||||

| 25 | 1.80 | |||||||

| 30 | 1.98 | |||||||

| 35 | 2.15 | 100 | ||||||

| 3° | 6 | 1.42 | 50 | |||||

| 10 | 1.84 | |||||||

|

1.5 | 1° | 10 | 0.1 0.2 0.3 | 1.74 | 1.2 | 50 | 4 | 1 |

| 15 | 1.92 | |||||||

| 20 | 2.09 | 70 | ||||||

| 25 | 2.27 | |||||||

| 30 | 2.44 | |||||||

| 3° | 10 | 2.23 | 50 | |||||

| 15 | 2.76 | |||||||

|

2 | 1° | 15 | 0.1 0.2 0.3 0.5 | 2.38 | 1.6 | 50 | 4 | 1 |

| 20 | 2.56 | 70 | ||||||

| 25 | 2.73 | |||||||

| 30 | 2.91 | |||||||

| 40 | 3.26 | 100 | ||||||

| 50 | 3.61 | |||||||

| 3° | 15 | 3.15 | 50 | |||||

| 20 | 3.68 | 70 | ||||||

|

3 | 1° | 15 | 0.2 0.5 | 3.31 | 2.4 | 70 | 6 | 2 |

| 20 | 3.49 | |||||||

| 30 | 3.84 | |||||||

| 40 | 4.19 | 100 | ||||||

| 50 | 4.54 | |||||||

| 60 | 4.89 |

Model Number

TN-TSC-CR-EM2S (Manufactured Product)

| Outer Diameter D | Radius R | Neck Gradient θ1 0.5° Increment Designation | Length Under Neck ℓ1 1 mm Increment Designation | Under Neck Diameter d1 | Flute Length ℓ | Overall Length L | Shank Diameter d | Figure |

|

1 | 0.1 0.2 0.3 | 2.5° ~ 5° | 7 ~ 19 | - | 2 | 40 | 4 | 2 |

|

1.5 | 0.1 0.2 0.3 | 2.5° ~ 3° | 8 ~ 20 | - | 3 | 40 | 4 | 2 |

| 0.1 0.2 0.3 | 3.5° ~ 5° | 8 ~ 17 | - | |||||

|

2 | 0.1 0.2 0.3 0.5 | 0.5° ~ 3° | 9 ~ 21 | - | 4 | 40 | 4 | 2 |

| 0.1 0.2 0.3 0.5 | 3.5° ~ 5° | 9 ~ 15 | - | |||||

|

3 | 0.1 0.2 0.3 0.5 | 0.5° ~ 5° | 9 ~ 15 | - | 6 | 45 | 6 | 2 |

[ ! ]When ordering manufactured products, be sure to refer to an ordering example as the points below differ from when ordering a stocked product.

(1) "TN-" is prepended to the start of the model number. (2) "S" is appended to the end of the model number. (3) The order for specifying the "radius" differs from that of stocked products.

For Cutting Conditions, Refer to >>Click here.

More Information

● It adopts a short flute length and back-tapered peripheral cutting edge for suppressing chatter.

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, yielding a longer operational life and is ideal for high speed machining / dry machining.