(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน มิถุนายน 2567 | Notice holiday in June 2024 > คลิก

Specification/Dimensions

-

R Size(mm)

-

Flute Length (ℓ)(mm)

-

Overall Length (L)(mm)

-

Length Under Neck (ℓ1)(mm)

-

Shank Diameter (d)(mm)

-

Inventory Classification

- Cutting Edge R Processing

- Standard Neck Relief

- Stocked Product

-

type

- SN-TSC-BEM4R

- SNR-TSC-BEM4R

- TSC-BEM4R

Days to Ship

-

- All

- 3 Day(s) or Less

- 5 Day(s) or Less

- 7 Day(s) or Less

Specify Alterations

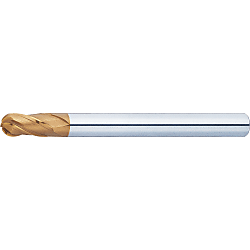

TSC series carbide ball end mill, 4-flute / regular model

- Volume Discount

- TS

- General Steel

- 4 Flutes

- R (Regular)

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Price :

- ---

-

- Qty :

-

-

- Days to Ship :

- ---

-

- Total Price :

- ---

Select part number to Order Now/ Add to Cart

Product Description

[Features]

·Surface coarse of workpiece after processing is very good finish.

·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. As coating characteristic, it is effective in high-speed machining and dry machining.

·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

| Part Number |

|---|

| SN-TSC-BEM4R3-[17-62/1]-12 |

| SN-TSC-BEM4R4-[20-65/1]-15 |

| SN-TSC-BEM4R5-[23-68/1]-18 |

| SN-TSC-BEM4R6-[27-72/1]-22 |

| SNR-TSC-BEM4R3-[17-62/1]-[5-12/1] |

| SNR-TSC-BEM4R4-[20-65/1]-[5-15/1] |

| SNR-TSC-BEM4R5-[23-68/1]-[5-18/1] |

| SNR-TSC-BEM4R6-[27-72/1]-[5-22/1] |

| TSC-BEM4R1.5 |

| TSC-BEM4R2 |

| TSC-BEM4R2.5 |

| TSC-BEM4R3 |

| TSC-BEM4R4 |

| TSC-BEM4R5 |

| TSC-BEM4R6 |

| Part Number | Price | Name | Minimum Order Qty. | Volume Discount | Days to Ship | R Size (mm) | Flute Length (ℓ) (mm) | Overall Length (L) (mm) | Length Under Neck (ℓ1) (mm) | Shank Diameter (d) (mm) | Inventory Classification | Outer Diameter D (mm) | Figure | Length Under Neck (θ) (Degree) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | END MILL | 1 Piece(s) | 7 Day(s) | 3 | 12 | 90 | 17 ~ 62 | 6 | Standard Neck Relief | 6 | 2 | - | ||

- | END MILL | 1 Piece(s) | 7 Day(s) | 4 | 15 | 100 | 20 ~ 65 | 8 | Standard Neck Relief | 8 | 2 | - | ||

- | END MILL | 1 Piece(s) | 7 Day(s) | 5 | 18 | 100 | 23 ~ 68 | 10 | Standard Neck Relief | 10 | 2 | - | ||

- | END MILL | 1 Piece(s) | 7 Day(s) | 6 | 22 | 110 | 27 ~ 72 | 12 | Standard Neck Relief | 12 | 2 | - | ||

- | END MILL | 1 Piece(s) | 5 Day(s) | 3 | 5 ~ 12 | 90 | 17 ~ 62 | 6 | Cutting Edge R Processing | 6 | 2 | - | ||

- | END MILL | 1 Piece(s) | 5 Day(s) | 4 | 5 ~ 15 | 100 | 20 ~ 65 | 8 | Cutting Edge R Processing | 8 | 2 | - | ||

- | END MILL | 1 Piece(s) | 5 Day(s) | 5 | 5 ~ 18 | 100 | 23 ~ 68 | 10 | Cutting Edge R Processing | 10 | 2 | - | ||

- | END MILL | 1 Piece(s) | 5 Day(s) | 6 | 5 ~ 22 | 110 | 27 ~ 72 | 12 | Cutting Edge R Processing | 12 | 2 | - | ||

฿ 1,076.00 | END MILL | 1 Piece(s) | 3 Day(s) | 1.5 | 8 | 60 | - | 6 | Stocked Product | 3 | 1 | 10° | ||

฿ 940.65 | END MILL | 1 Piece(s) | Available | 3 Day(s) | 2 | 8 | 70 | - | 6 | Stocked Product | 4 | 1 | 10° | |

฿ 1,233.57 | END MILL | 1 Piece(s) | Available | 3 Day(s) | 2.5 | 12 | 80 | - | 6 | Stocked Product | 5 | 1 | 10° | |

฿ 1,224.00 | END MILL | 1 Piece(s) | 3 Day(s) | 3 | 12 | 90 | - | 6 | Stocked Product | 6 | 2 | - | ||

฿ 1,811.00 | END MILL | 1 Piece(s) | 3 Day(s) | 4 | 15 | 100 | - | 8 | Stocked Product | 8 | 2 | - | ||

฿ 2,463.00 | END MILL | 1 Piece(s) | 3 Day(s) | 5 | 18 | 100 | - | 10 | Stocked Product | 10 | 2 | - | ||

฿ 3,287.00 | END MILL | 1 Piece(s) | 3 Day(s) | 6 | 22 | 110 | - | 12 | Stocked Product | 12 | 2 | - |

Loading...

Specifications

| Model Number | Flute Length ℓ |

Outer Diameter D |

Overall Length L |

Shank Diameter d |

Figure | |

| Tip R |

||||||

| TSC-BEM4R | 1.5 | 8 | 3 | 60 | 6 | 1 |

| 2 | 8 | 4 | 70 | 6 | 1 | |

| 2.5 | 12 | 5 | 80 | 6 | 1 | |

| 3 | 12 | 6 | 90 | 6 | 2 | |

| 4 | 15 | 8 | 100 | 8 | 2 | |

| 5 | 18 | 10 | 100 | 10 | 2 | |

| 6 | 22 | 12 | 110 | 12 | 2 |

For Cutting Conditions, Refer to >>Click here.

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● Delivers a finish with a very good working surface roughness after machining.

Basic Information

| Model | Bore | Work Material | General Steel / Heat-Treated Steel / High-Hardness Steel ~ HRC55 / Stainless Steel / Cast Iron / Aluminum / Copper | Number of Flutes(sheet) | 4 |

|---|---|---|---|---|---|

| Coating | For High Hardness (Silicone-Based) | R Precision(μm) | ±0.01 | Processing Applications | Curved Surface / Side Surface / Carving / R-Groove |

| Torsion Availability | Included |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

How can we improve?

How can we improve?