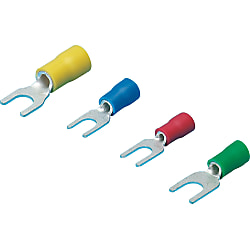

Insulated Crimp Terminal, Y Shape

Caution

Product Description

Insulated Crimp Terminal, Y Shape [100 Pieces Per Package]

There are many sizes of this equipment available for connecting wires to a terminal.

[Features]

• Compatible electric wire size (AWG): 26-24, 20-16, 16-14 and 12-10

• Compatible electric stranded wire size (mm²): 0.1-0.3 ,0.5-1.65, 1.04-2.63 and 2.63-6.64

• Rated Voltage (AC): 300V

• Withstand Voltage (AC): 3000V

• Representative Standard: UL E74917 and CSA LR66230

[Applications]

It is used for connecting the wire and electric components.

● Most commonly used Y-model crimp terminals with insulation.

● UL (E74917), CSA (LR66230) acquired high quality crimp terminals. (RVF 0.3-3 has UL certification only)

· Perform crimping with the dedicated crimping tools.

· This product is not waterproof. Avoid using it in places exposed to water.

· Available from 1 pack (100 pieces).

· This product is manufactured by Daido Solderless Terminal MFG, and stocked and sold with MISUMI model numbers.

· Estimation for colors and sizes not in the catalog are available using manufacturer model numbers. Refer to the e-Catalog for details.

Specifications

| 1 Pack | 100-piece Pack |

| Model Number | Color | Applicable Electric Wire Range | |

| Stranded Wire (mm2) | AWG Size | ||

| BVF0.3-3YE | Yellow | 0.1-0.3 | 26-24 |

| BVF1.25-3RE | Red | 0.5-1.65 | 20-16 |

| BVF1.25-3GR | Green | ||

| BVF1.25-3.5RE | Red | ||

| BVF1.25-3.5GR | Green | ||

| BVF1.25-4RE | Red | ||

| BVF1.25-4GR | Green | ||

| BVF1.25-5RE | Red | ||

| BVF1.25-5GR | Green | ||

| BVF2-3.5BU | Blue | 1.04-2.63 | 16-14 |

| BVF2-3.5GR | Green | ||

| BVF2-4BU | Blue | ||

| BVF2-4GR | Green | ||

| BVF2-5BU | Blue | ||

| BVF2-5GR | Green | ||

| BVF5.5-4YE | Yellow | 2.63-6.64 | 12-10 |

| BVF5.5-4GR | Green | ||

| BVF5.5-5YE | Yellow | ||

| BVF5.5-5GR | Green | ||

| BVF5.5-6YE | Yellow | ||

| BVF5.5-6GR | Green | ||

Features

● Crimp terminals are wire connection components that are used in a wide range of applications such as electrical engineering as well as domestic electrical appliances, measuring devices, FA control devices etc.● Available in 2 types: conventional type bare crimp terminals without insulation sheathing, and crimp terminals with insulation sleeves.

● We also offer products with JIS, UL and CSA certification, allowing for use with peace of mind.

Allowable Current

| Wire Size Used | Terminal Nominal Number | Allowable current or less (at 30°C) | ||||

|---|---|---|---|---|---|---|

| Single Wire | Stranded Wire | AWG | With rubber vinyl insulated wire | Cord | ||

| Single Wire | Stranded Wire | |||||

| - | 0.08 | 28 | 0.08 | - | - | - |

| - | 0.3 | 26, 24 | 0.3 | - | - | - |

| 0.8 | 0.3, 0.5 | 22, 20 | 0.5 | - | - | - |

| 1.0, 1.2 | 0.75, 0.9, 1.25 | 18, 16 | 1.25 | 16 A, 19 A | 16 A, 17 A, 19 A | 7 A (0.75 mm), 12 A |

| 1.6 | 2 | 14 | 2 | 27 A | 27 A | 17 A |

| 2.0 | 3.5 | 12 | 3.5 | 35 A | 37 A | 23 A |

| 2.6 | 5.5 | 10 | 5.5 | 48 A | 48 A | 35 A |

| 3.2 | 8 | 8 | 8 | 62 A | 62 A | - |

Allowable Voltage

Bare Crimp Terminal: 600 VAC or lessInsulated Crimp Terminal: 300 VAC or less

Materials

Conductor Component: Oxygen-free Copper (Tin-Plated)Insulator Component: Refer to product pages

Compatible Wire Size

Refer to product pages.Crimping Method

Diagram A

| Terminal Nominal (Note 3) | Wire Size Used | Wire Sheath Strip Dimensions (mm) | ||||

|---|---|---|---|---|---|---|

| Stranded Wire (mm2) | Single Wire (Dia. mm) | Wire Conjugation Capacity (Note 1) | L (Note 2) | L1 | L2 | |

| 0.08 | 0.08 | - | - | B + L1 + L2 | 0.5 ~ 2 | 0 ~ 1 |

| 1.25 | 0.3, 0.5, 0.75, 0.9, 1.25 | 0.75 ~ 1.44 | 0.25 ~ 1.65 | B + L1 + L2 | 0.5 ~ 2 | 0 ~ 1 |

| 2 | 1.25, 2.0 | 1.14 ~ 1.82 | 1.04 ~ 2.63 | B + L1 + L2 | 0.5 ~ 2 | 0 ~ 1 |

| 5.5 | 3.5, 5.5 | 1.82 ~ 2.89 | 2.63 ~ 6.64 | B + L1 + L2 | 0.5 ~ 2 | 0 ~ 1 |

| 8 | 8 | 2.89 ~ 3.65 | 6.64 ~ 10.52 | B + L1 + L2 | 1 ~ 2 | 0 ~ 2 |

(Note 2) The calculation method of the L dimension is simply for finding the dimensions of the wire sheath stripping, and is not used to indicate the shape or dimensions after crimping.

(Note 3) For applicable wires at 0.3, use a conductor cross-sectional area close to the terminal nominal. Furthermore, fold back the core wire when crimping thin types such as AWG28.

Also, ensure that the wire stripping dimension complies with the terminal nominal 1.25.

Crimping Guideline

Selection of Crimping Tool

Visual Inspection after Crimping