TRVVP Shielded Robot Cables 300V

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

Robot Cables are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Rated Voltage : 300V

● Conductor : Copper (no coating)

● Conductor Cross Section Minimum/Maximum(mm²) : 0.15 and 0.5

● Number Of Cores : 2, 3, 4, 5 and 6

● AWG size : 20 ,22, 24 and 26

[Application]

Robot Cables are commonly used in various applications in factory automation systems

Specification of Machinery Robot Cables

| Conductor Cross Section (mm2) | Number of Cores (1Pair=2Cores) | AWG Size | Twisting Structure | Number of Wire Core | Cable O.D. (mm | Reference Weight kg/km | Electrical Properties | Conductor | Insulation | Wire Core O.D. approx. (mm) | Sheath | |||||||

| Allowable Current A (30℃) | Conductor Resistance Ω/km (20℃) | Insulation Properties MΩ/km (20℃) | MAX Voltage V/min | Structure Strands/ mm | O.D. approx. (mm) | Electro plating | Thickness (mm) | Material | Thickness (mm) | Material | ||||||||

| 0.15 | 2 | 26 | Stranded Wire | 2 | 4.5 | 31 | 3.8 | 140 or Less | 10 or More | 2000 | 13/0.12 | 0.5 | None | 0.3 | PVC | 1.1 | 0.9 | PVC |

| 3 | 3 | 4.7 | 34 | 3.2 | 0.9 | |||||||||||||

| 4 | 4 | 5.0 | 38 | 2.9 | 0.9 | |||||||||||||

| 5 | 5 | 5.3 | 44 | 2.6 | 0.9 | |||||||||||||

| 6 | 6 | 5.6 | 49 | 2.5 | 0.9 | |||||||||||||

| 0.2 | 2 | 24 | 2 | 4.7 | 34 | 4.7 | 94.2 or Less | 10 or More | 2000 | 19/0.12 | 0.6 | 0.3 | 1.2 | 0.9 | ||||

| 3 | 3 | 4.9 | 39 | 4.0 | 0.9 | |||||||||||||

| 4 | 4 | 5.2 | 44 | 3.6 | 0.9 | |||||||||||||

| 5 | 5 | 5.5 | 50 | 3.3 | 0.9 | |||||||||||||

| 6 | 6 | 5.9 | 58 | 3.1 | 0.9 | |||||||||||||

| 0.3 | 2 | 22 | 2 | 5.0 | 38 | 5.5 | 69.2 or Less | 10 or More | 2000 | 24/0.12 | 0.65 | 0.35 | 1.35 | 0.9 | ||||

| 3 | 3 | 5.2 | 44 | 4.6 | 0.9 | |||||||||||||

| 4 | 4 | 5.6 | 52 | 4.1 | 0.9 | |||||||||||||

| 5 | 5 | 5.9 | 58 | 3.8 | 0.9 | |||||||||||||

| 6 | 6 | 6.4 | 67 | 3.6 | 0.9 | |||||||||||||

| 0.5 | 2 | 20 | 2 | 6.1 | 59 | 8.6 | 39 or Less | 10 or More | 2000 | 42/0.12 | 0.9 | 0.45 | 1.8 | 1.0 | ||||

| 3 | 3 | 6.4 | 72 | 7.2 | 1.0 | |||||||||||||

| 4 | 4 | 6.8 | 83 | 6.5 | 1.0 | |||||||||||||

| 5 | 5 | 7.4 | 98 | 6.0 | 1.0 | |||||||||||||

| 6 | 6 | 7.9 | 116 | 5.7 | 1.0 | |||||||||||||

Product Feature of Machinery Robot Cables

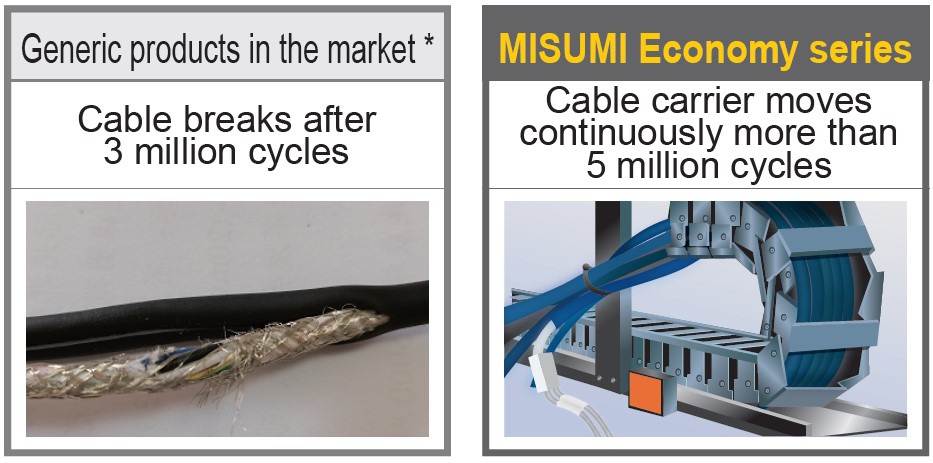

■ Moving Performance of Machinery Robot Cables

・Moving Stroke S=500mm

・Moving Speed 1000mm/s

・Bending Radius R=6D

* Generic products in the market are similar products randomly purchased by our company from online or offline markets

* The test data are obtained through testing by our company, which are for reference only

Product Overview of Machinery Robot Cables

●Material:PVC Black Sheath, Oxyge-Free Copper Conductor, Shielded,Twisted Structure

●Applicable in semiconductors, Low-Speed moving part in electric equipment and cable carriers

●Shielded Type

●Sealded Twisted pair

Specification of Machinery Robot Cables

●Cross Section

*With the specifications and filling volume , please refer to the actual product.

●Moving Performance of Machinery Robot Cables

| Test Result | Endured more than 5 million cycles |

| |

| Testing Method | Cable Drag Chain |

| Test Conditions | ・Moving Stroke S=500mm |

| ・Moving Speed 1000mm/s | |

| ・Bending Radius R=6D |

| Core | 1 | 2 | 3 | 4 | 5 | 6 |

| Insulation Color | Black | Red | Yellow Green | White | Green | Blue |

Dimension of Machinery Robot Cables

| Series | Conductor Cross Section(mm2) | AWG Size | Number of Cores | Twisting Structure | Shield | Sheath Materia | Conductor | Rated Voltage |

Shielded | 0.15 | 26 | 2-6 | Stranded Wire | Copper braid | PVC | Copper (no coating) | 300V |

| 0.2 | 24 | |||||||

| 0.3 | 22 | |||||||

| 0.5 | 20 |

For wire cross-sectional area/AWG size conversion, please refer to our catalog:htttps://th.misumi-ec.com/en/linked/en/pdf/_pdf/wire_table.pdf

Machinery Robot Cables, The calculation method of cross-sectional area is different,The AWG value is for reference only, please refer to the cross-sectional area of the cable conductor for design and selection.

Product Features of Machinery Robot Cables

| Category | Spec | Condition | Remark | ||

| Insulation Properties | Tensile Strength | (Lbf/in2) | 1460 or More | - | Testing Method: ·GB/T2951.11-2008 ·GB/T2951.12-2008 |

| (Mpa) | 10 or More | - | |||

| Elongation | (%) | 150 or More | - | ||

| Tensile strength after aging | (%) | 80 or More | - | ||

| Elongation after aging | (%) | 80 or More | - | ||

| Aging Condition | 80℃ 168hours | ||||

| Tensile Strength | (Lbf/in2) | 1500 or More | - |  | |

| (Mpa) | 10.3 or More | - | |||

| Elongation | (%) | 100 or More | - | ||

| Tensile strength after aging | (%) | 70 or More | - | ||

| Elongation after aging | (%) | 70 or More | - | ||

| Aging Condition | 113℃ 168hours | ||||

| Sheath Properties | Tensile Strength | (Lbf/in2) | 1500 or More | - | Testing Method: ·GB/T2951.11-2008 ·GB/T2951.12-2008 ·Flame retardancy test Conform GB/T18380.12 |

| (Mpa) | 10 or More | - | |||

| Elongation | (%) | 150 or More | - | ||

| Tensile strength after aging | (%) | 80 or More | - | ||

| Elongation after aging | (%) | 80 or More | - | ||

| Aging Condition | 80℃ 168Hours | ||||

| Tensile Strength | (Lbf/in2) | 150 or More | - |  | |

| (Mpa) | 10.3 or More | - | |||

| Elongation | (%) | 100 or More | - | ||

| Tensile strength after aging | (%) | 70 or More | - | ||

| Elongation after aging | (%) | 70 or More | - | ||

| Aging Condition | 113℃ 168hours | ||||

●Characteristic of Machinery Robot Cables

| Conductor Cross Section (mm2) | Number of Cores (1Pair=2Cores) | AWG Size | Twisting Structure | Number of Wire Core | Cable O.D. (mm | Reference Weight kg/km | Electrical Properties | Conductor | Insulation | Wire Core O.D. approx. (mm) | Sheath | |||||||

| Allowable Current A (30℃) | Conductor Resistance Ω/km (20℃) | Insulation Properties MΩ/km (20℃) | MAX Voltage V/min | Structure Strands/ mm | O.D. approx. (mm) | Electro plating | Thickness (mm) | Material | Thickness (mm) | Material | ||||||||

| 0.15 | 2 | 26 | Stranded Wire | 2 | 4.5 | 31 | 3.8 | 140 or Less | 10 or More | 2000 | 13/0.12 | 0.5 | None | 0.3 | PVC | 1.1 | 0.9 | PVC |

| 3 | 3 | 4.7 | 34 | 3.2 | 0.9 | |||||||||||||

| 4 | 4 | 5.0 | 38 | 2.9 | 0.9 | |||||||||||||

| 5 | 5 | 5.3 | 44 | 2.6 | 0.9 | |||||||||||||

| 6 | 6 | 5.6 | 49 | 2.5 | 0.9 | |||||||||||||

| 0.2 | 2 | 24 | 2 | 4.7 | 34 | 4.7 | 94.2 or Less | 10 or More | 2000 | 19/0.12 | 0.6 | 0.3 | 1.2 | 0.9 | ||||

| 3 | 3 | 4.9 | 39 | 4.0 | 0.9 | |||||||||||||

| 4 | 4 | 5.2 | 44 | 3.6 | 0.9 | |||||||||||||

| 5 | 5 | 5.5 | 50 | 3.3 | 0.9 | |||||||||||||

| 6 | 6 | 5.9 | 58 | 3.1 | 0.9 | |||||||||||||

| 0.3 | 2 | 22 | 2 | 5.0 | 38 | 5.5 | 69.2 or Less | 10 or More | 2000 | 24/0.12 | 0.65 | 0.35 | 1.35 | 0.9 | ||||

| 3 | 3 | 5.2 | 44 | 4.6 | 0.9 | |||||||||||||

| 4 | 4 | 5.6 | 52 | 4.1 | 0.9 | |||||||||||||

| 5 | 5 | 5.9 | 58 | 3.8 | 0.9 | |||||||||||||

| 6 | 6 | 6.4 | 67 | 3.6 | 0.9 | |||||||||||||

| 0.5 | 2 | 20 | 2 | 6.1 | 59 | 8.6 | 39 or Less | 10 or More | 2000 | 42/0.12 | 0.9 | 0.45 | 1.8 | 1.0 | ||||

| 3 | 3 | 6.4 | 72 | 7.2 | 1.0 | |||||||||||||

| 4 | 4 | 6.8 | 83 | 6.5 | 1.0 | |||||||||||||

| 5 | 5 | 7.4 | 98 | 6.0 | 1.0 | |||||||||||||

| 6 | 6 | 7.9 | 116 | 5.7 | 1.0 | |||||||||||||