Heat Shrink Tubes Ground Coloring, Shrinkage2:1

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

This is an economy item, The price is cheaper than the MISUMI standard product.

[Features]

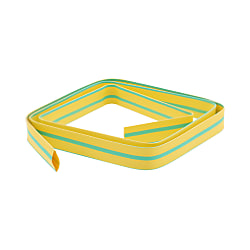

Shrink tube color: yellow and green

Shrinkage ratio 2:1

Temperature range for shrink tubing use -55°C to +125°C

Flame retardant VW-1

Flame retardant for black model

Made from radiation cross-linked polyolefin material.

Environmentally friendly thermoplastic pipe

Economy Ground Colored Heat Shrink Tube

- Color-Coded Identification: Distinct yellow and green colors for easy ground wire identification in wire harnesses and cables.

- Shrinkage Ratio: Specified ratio for efficient insulation and protection.

- Material: Environmentally friendly, radiation cross-linked polyolefin for durability and flexibility.

- Temperature Resistance: Operates in temperatures from -55°C to +125°C for various applications.

- Electrical Insulation: Provides reliable insulation protection.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product of heat shrink tube Overview

● heat shrink tube Material: the environment-friendly thermoplastic tube is made of radiation cross-linked polyolefin material● heat shrink tube Color: Yellow and green

● heat shrink tube: fast shrinkage and convenient

● Application: the product has yellow and green appearance, and is widely used for identification of ground wire in wire harness or cable, identification of special cable and bus or pipeline, etc.

* Note: each roll of heat shrink tube may have 1 to 3 adapters, which conforms to the industry standard and does not affect the quality. Please feel free to use.

Product of heat shrink tube Feature

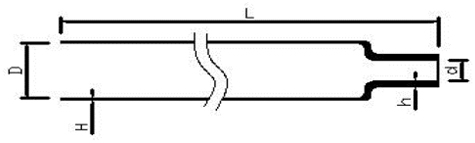

Dimensional of heat shrink tube Drawing

| Part number | Before heat shrink tube (mm) | After heat shrink tube (mm) | |||||

| Inner Diameter D | Inner Diameter d | Wall Thickness h | |||||

| MTUBE-YG-1 | 1.50±0.3 | ≤0.70 | 0.28±0.10 | ||||

| MTUBE-YG-2 | 2.50±0.3 | ≤1.00 | 0.35±0.10 | ||||

| MTUBE-YG-3 | 3.50±0.4 | ≤1.50 | 0.38±0.10 | ||||

| MTUBE-YG-4 | 4.50±0.4 | ≤2.00 | 0.45±0.10 | ||||

| MTUBE-YG-5 | 5.50±0.4 | ≤2.50 | 0.45±0.10 | ||||

| MTUBE-YG-6 | 6.50±0.4 | ≤3.00 | 0.50±0.10 | ||||

| MTUBE-YG-7 | 7.50±0.4 | ≤3.50 | 0.50±0.10 | ||||

| MTUBE-YG-8 | 8.50±0.5 | ≤4.00 | 0.55±0.10 | ||||

| MTUBE-YG-9 | 9.50±0.5 | ≤4.50 | 0.55±0.10 | ||||

| MTUBE-YG-10 | 10.5±0.5 | ≤5.00 | 0.55±0.10 | ||||

| MTUBE-YG-11 | 11.5±0.5 | ≤5.50 | 0.60±0.10 | ||||

| MTUBE-YG-12 | 12.5±0.5 | ≤6.00 | 0.60±0.10 | ||||

| MTUBE-YG-15 | 15.5±0.6 | ≤7.50 | 0.70±0.15 | ||||

| MTUBE-YG-20 | 22.0±0.7 | ≤10.00 | 0.80±0.15 | ||||

Specifications of heat shrink tube Overview

| heat shrink tube Material | heat shrink tube Polyolefin |

| Shrinkage Ratio | ‘2:1 |

| Operating Temperature Range | -55℃~+125℃ |

| Initial Shrinkage Temperature | 70℃ |

| Minimum Complete Shrinkage Temperature | 125℃ |

| Flame Retardant (Black Flame Retardant, Transparent Non-flame Retardant) | VW-1 |

| heat shrink tube Item | heat shrink tube Test Method | heat shrink tube Test Result |

| Tensile Strength | ASTM D2671 | ≥10.4MPa |

| Breakage Elongation | ASTM D2671 | ≥200% |

| Tensile Strength after Aging | UL224(158℃ 168H) | ≥7.3MPa |

| Breakage Elongation After Aging | UL224 (158℃ 168H) | ≥100% |

| Longitudinal Shrinkage Rate | ≤8% | |

| Dielectric Strength | IEC 243 | ≥15KV/mm |

| Volume Resistivity | IEC 93 | ≥1014Ω.cm |

| Flame Retardance | UL224 | VW-1 |

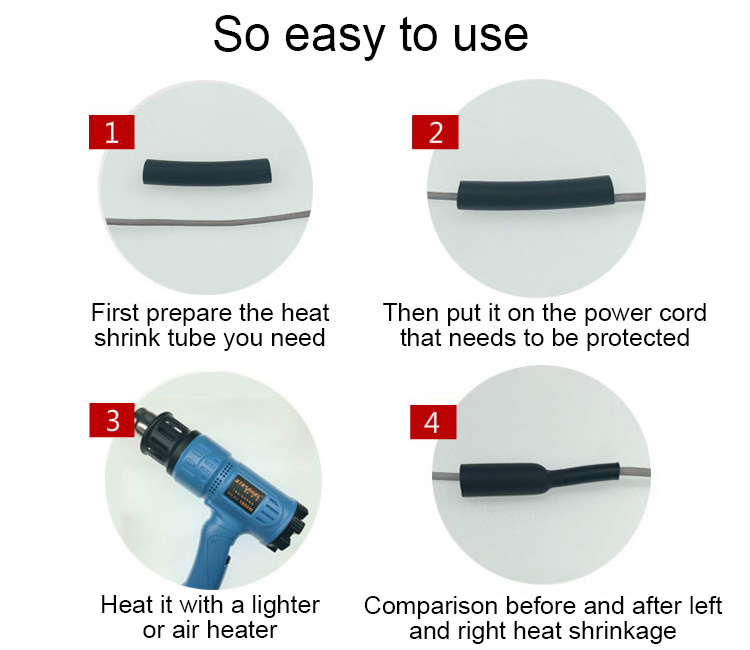

Usage of heat shrink tube Method

Example of heat shrink tube Use

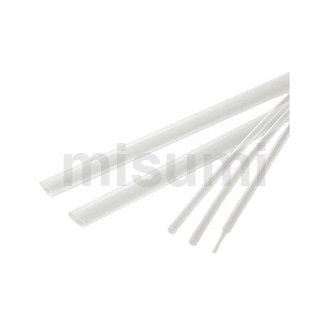

Related of heat shrink tube Products

| (Economy series) heat shrink tube 2:1 Printing Tube Halogen Free | (Economy series) heat shrink tube 3:1 Double-wall Adhesive Lined | (Economy series) heat shrink tube Fluororesin Heat Resistant |

|  |  |