Heat Shrink Tubes Flame Retardant, Shrinkage2:1 Ultra-Thin Wall

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

This is an economy item, The price is cheaper than the MISUMI standard product.

[Features]

The shrink tube material is made from radiopaque cross-linked polyolefin material.

The black version is an ultra-thin single-wall shrink tube.

Used to provide insulation protection for wires, cables and connectors.

Shrinkage ratio 2:1

Operating temperature range -55°C to +125°C

Flame retardant VW-1

Economy Heat Shrink Tubes Flame Retardant

- Shrinkage Ratio: It has a specified shrinkage ratio.

- Material: Made from radiopaque cross-linked polyolefin material.

- Wall Thickness: Ultra-thin single-wall design.

- Temperature Range: Operates in temperatures from -55°C to +125°C.

- Flame Retardant: Meets VW-1 flame retardant standard.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product of heat shrink tube Overview

● heat shrink tube Material: the environment-friendly thermoplastic tube is made of radiation cross-linked polyolefin material● heat shrink tube Performance: ultra-thin single-wall heat shrink tube black model

● heat shrink tube Application: provide insulation protection for wires, cables and wire terminals, featuring high-temperature shrinkage, soft flame retardant, insulation corrosion prevention, etc., widely used for insulation protection of various wire harnesses, welding points, inductors and rust prevention and corrosion prevention of metal tubes and rods.

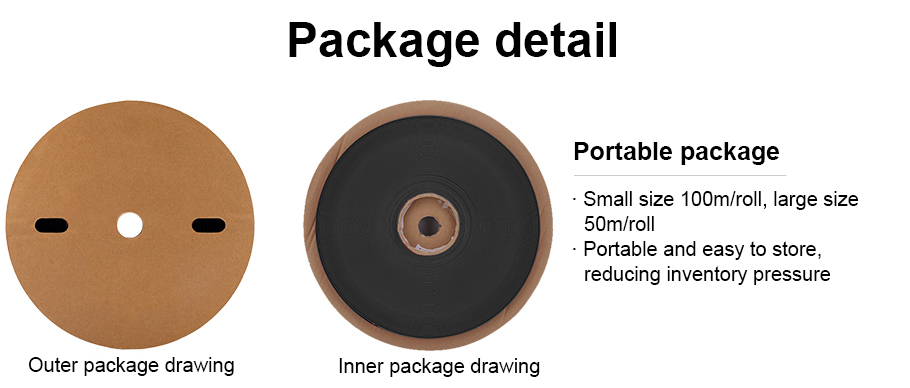

** Note: each roll of heat shrink tube may have 1 to 3 adapters, which conforms to the industry standard and does not affect the quality. Please feel free to use.

Product of heat shrink tube Feature

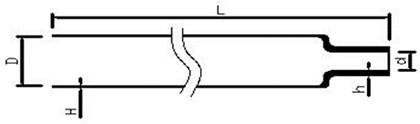

Dimensional heat shrink tube Drawing

| Part number | Before heat shrink tube (mm) | After heat shrink tube (mm) | ||

| Inner Diameter D | Average Wall Thickness H | Inner Diameter d | Wall Thickness h | |

| MTUBE-CB-0.6 | 0.9±0.2 | 0.10±0.03 | ≤0.40 | 0.20±0.10 |

| MTUBE-CB-0.8 | 1.1±0.2 | 0.11±0.03 | ≤0.50 | 0.20±0.10 |

| MTUBE-CB-1 | 1.5±0.2 | 0.12±0.03 | ≤0.65 | 0.20±0.10 |

| MTUBE-CB-2 | 2.5±0.3 | 0.13±0.03 | ≤1.00 | 0.22±0.10 |

| MTUBE-CB-3 | 3.5±0.4 | 0.13±0.04 | ≤1.50 | 0.28±0.10 |

| MTUBE-CB-4 | 4.5±0.4 | 0.15±0.04 | ≤2.00 | 0.30±0.10 |

| MTUBE-CB-5 | 5.5±0.4 | 0.15±0.04 | ≤2.50 | 0.32±0.10 |

| MTUBE-CB-6 | 6.5±0.4 | 0.15±0.04 | ≤3.00 | 0.32±0.10 |

| MTUBE-CB-7 | 7.5±0.4 | 0.15±0.04 | ≤3.50 | 0.32±0.10 |

| MTUBE-CB-8 | 8.5±0.5 | 0.15±0.04 | ≤4.00 | 0.32±0.10 |

| MTUBE-CB-9 | 9.5±0.5 | 0.15±0.04 | ≤4.50 | 0.35±0.10 |

| MTUBE-CB-10 | 10.5±0.5 | 0.15±0.04 | ≤5.00 | 0.35±0.10 |

| MTUBE-CB-11 | 11.5±0.5 | 0.18±0.04 | ≤5.50 | 0.40±0.10 |

| MTUBE-CB-12 | 12.5±0.5 | 0.20±0.05 | ≤6.00 | 0.40±0.10 |

| MTUBE-CB-15 | 15.5±0.5 | 0.20±0.05 | ≤7.50 | 0.40±0.10 |

| MTUBE-CB-20 | 20.5±0.5 | 0.25±0.05 | ≤10.00 | 0.45±0.10 |

| MTUBE-CB-25 | 25.5±0.5 | 0.25±0.05 | ≤12.50 | 0.45±0.10 |

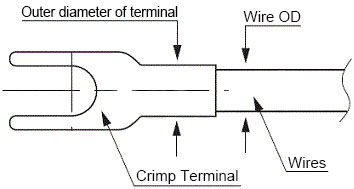

Example of specification selection of heat shrink tube:

.jpg)

| Wire Cross-sectional Area (mm2) | Wire O.D.(φmm) | Applicable Shrink Tube I.D. (φmm) |

| 0.75 | 2.8 | 3.0 |

| 1.25 | 3.0 | 3.2 |

| 2.0 | 3.4 | 3.6 |

| 3.5 | 4.0 | 4.2 |

| 5.5 | 5.0 | 5.1 |

.jpg)

| Wire Cross-sectional Area (mm2) | Terminal O.D. (φmm) | Applicable Shrink Tube I.D. (φmm) |

| 0.75 | - | - |

| 1.25 | 3.2 | 3.4 |

| 2.0 | 3.9 | 4.0 |

| 3.5 | 5.0 | 5.1 |

| 5.5 | 5.4 | 5.5 |

Specifications of heat shrink tube Overview

| heat shrink tube Material | heat shrink tube Polyolefin |

| heat shrink tube Ratio | ‘2:1 |

| Operating Temperature Range | -55℃~+125℃ |

| Initial Shrinkage Temperature | 70℃ |

| Minimum Complete Shrinkage Temperature | 110℃ |

| Flame Retardance | VW-1 |

| heat shrink tube Item | Test heat shrink tube Method | Test Result |

| Tensile Strength | GB/T 1040 | ≥10.4MPa |

| Breakage Elongation | GB/T 1040 | ≥200% |

| Tensile Strength after Aging | UL224(158℃ 168H) | ≥7.3MPa |

| Breakage Elongation After Aging | UL224 (158℃ 168H) | ≥100% |

| Shrinkage Rate/Longitudinal Shrinkage Rate | 2:1/≤8% | |

| Withstand Voltage Class 300V | UL224 | 1500V1min no breakdown |

| Dielectric Strength | GB/T 1408 | ≥15KV/mm |

| Volume Resistivity | GB/T 1410 | ≥1014Ω.cm |

| Flame Retardant (Except for transparent tubes) | UL224 | VW-1 |

| Copper Stability | UL224 158℃*168H | pass |

| Corrosion Resistance | UL224 158℃*168H | pass |

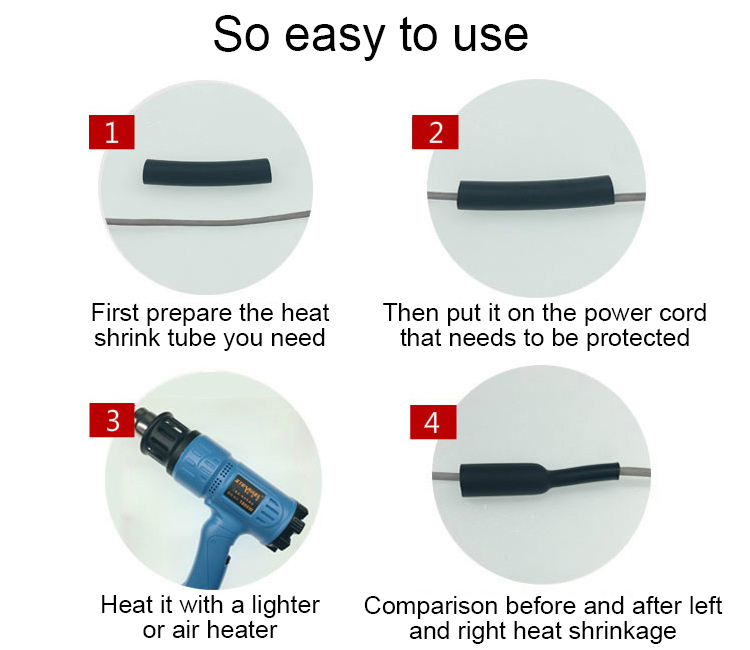

Usage of heat shrink tube Method

Example of heat shrink tube Use

Related of heat shrink tube Products

| (Economy series) heat shrink tube 2:1 Printing Tube Halogen Free | (Economy series) heat shrink tube 3:1 Double-wall Adhesive Lined | (Economy series) heat shrink tube 4:1 Double-wall Adhesive Lined |

|  |  |