Linear Guide Wide Block-Low Profile EG Type (ROHS Compliant)

Brand :

MISUMI

Caution

- This product specification (Catalog) supports lengths up to 4000mm. However, due to transportation costs, we are offering lengths up to 2000mm in the Thailand market.

For orders exceeding 2000mm, please contact MISUMI for special assistance. - Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

RoHS Comliant Economy Series Linear Guides

Product Overview

The Linear Guide, also known as a guide rail, linear rail, or linear slide rail, is used for linear reciprocating motion applications. It has a higher rated load and linear motion accuracy than linear bearings within the same component volume. It can also bear a certain torque load, achieving high-precision linear motion under heavy load conditions.

Linear Guides are used to support and guide moving parts, performing reciprocating linear motion in a specified direction. They are mainly used in machinery structures that require high precision. Instead of an intermediary medium, rolling steel balls are used between the moving and fixed components of the Linear Guide.

Linear Guides are used to support and guide moving parts, performing reciprocating linear motion in a specified direction. They are mainly used in machinery structures that require high precision. Instead of an intermediary medium, rolling steel balls are used between the moving and fixed components of the Linear Guide.

Product Features

Feature 1: Standard Seal for the rail to prevent dirt accumulation in the mounting holes during equipment use.

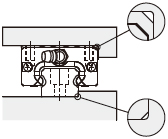

Feature 2: The rail and sliding block are connected by rolling balls, minimizing wobble, making them suitable for precision-demanding equipment.

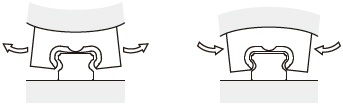

Feature 3: Point-to-surface contact results in minimal frictional resistance, achiving fine movement and precise positioning.

Feature 4: Since the balls have their own rolling grooves, the force on the rolling surface is distributed, allowing for a higher load capacity.

Feature 5: Linear Guides are less likely generate frictional heat during operation and are resistant to thermal deformation, making them suitable for high-speed motion.

Feature 2: The rail and sliding block are connected by rolling balls, minimizing wobble, making them suitable for precision-demanding equipment.

Feature 3: Point-to-surface contact results in minimal frictional resistance, achiving fine movement and precise positioning.

Feature 4: Since the balls have their own rolling grooves, the force on the rolling surface is distributed, allowing for a higher load capacity.

Feature 5: Linear Guides are less likely generate frictional heat during operation and are resistant to thermal deformation, making them suitable for high-speed motion.

Example of Use

■About Usage

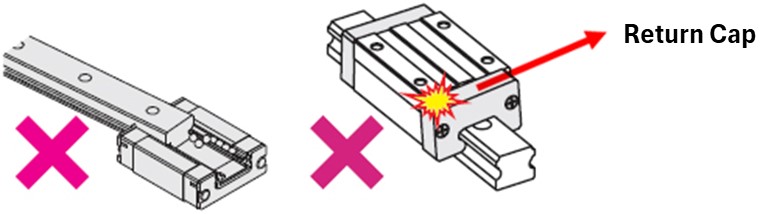

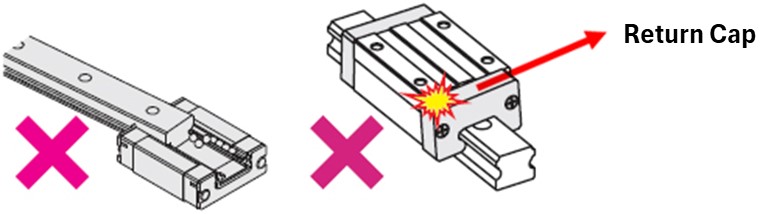

① MISUMI Linear Guides are equipped with retainers, so steel balls are not easily dislodged when removing the sliding block. However, if the block is removed from the rail at high speed or inserted at an angle, balls may dislodge. Please disassemble and reassemble the block carefully.

②Avoid hitting the ball return cap plate, as this may disrupt ball circulation, resulting in poor sliding performance.

③For rust prevention, it is recommended to choose products with low-temperature black chrome plating or stainless steel SUS440C material.

*Currently this series do not have both low temperature block chorome plating and SUS440C models

■Maintenance (Lubricant Application)

①Lubricant forms an oil film on the surface of the balls and rail of the Linear Guides, effectively reducing friction and preventing sintering.

Decrease and aging of lubricant can significantly impact the lifespan of the Linear Guide, so please replenish lubricant as needed according to usage conditions.

MISUMI Linear Guides are pre-lubricated at the factory, so they can be used directly.

②Recommended Lubrication Interval:

① MISUMI Linear Guides are equipped with retainers, so steel balls are not easily dislodged when removing the sliding block. However, if the block is removed from the rail at high speed or inserted at an angle, balls may dislodge. Please disassemble and reassemble the block carefully.

②Avoid hitting the ball return cap plate, as this may disrupt ball circulation, resulting in poor sliding performance.

③For rust prevention, it is recommended to choose products with low-temperature black chrome plating or stainless steel SUS440C material.

*Currently this series do not have both low temperature block chorome plating and SUS440C models

■Maintenance (Lubricant Application)

①Lubricant forms an oil film on the surface of the balls and rail of the Linear Guides, effectively reducing friction and preventing sintering.

Decrease and aging of lubricant can significantly impact the lifespan of the Linear Guide, so please replenish lubricant as needed according to usage conditions.

MISUMI Linear Guides are pre-lubricated at the factory, so they can be used directly.

②Recommended Lubrication Interval:

Typically, lubricate once every 3 months.

Adjust the maintenance interval as needed, with a recommended lubricant check every 100 km.

**The lubrication interval is based on standard travel distance. In harsh environments with severe lubricant aging or contamination, shorten the interval accordingly.

Adjust the maintenance interval as needed, with a recommended lubricant check every 100 km.

**The lubrication interval is based on standard travel distance. In harsh environments with severe lubricant aging or contamination, shorten the interval accordingly.

Precautions

To ensure proper usage, Linear Guide installation must meet the following 4 points:

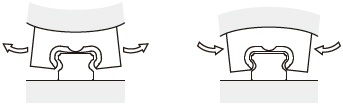

①Ensure no interference in the installation surface shape.

②Maintain the flatness of the workpiece installation surface within approximately 5μ, or the sliding blocks may slightly deform.

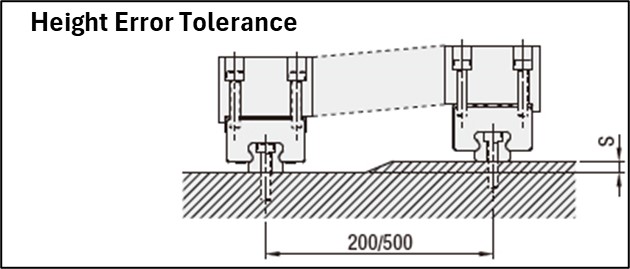

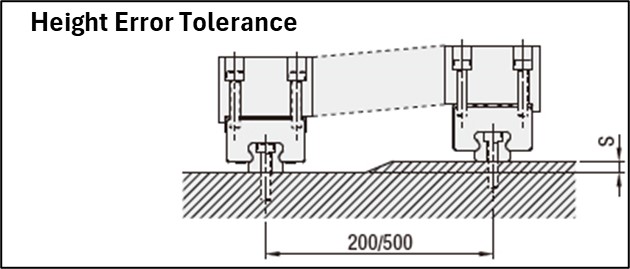

③Ensure that rail parallelism and height alignment error values are within allowable installation limits.

④Use a standardized installation method.

For detailed installation instructions, click here.

click here.

②Maintain the flatness of the workpiece installation surface within approximately 5μ, or the sliding blocks may slightly deform.

③Ensure that rail parallelism and height alignment error values are within allowable installation limits.

④Use a standardized installation method.

For detailed installation instructions,

click here.

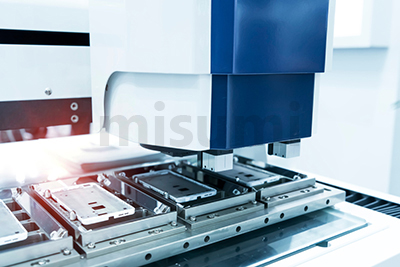

click here. Application Example

Mechanism Name: Belt-Driven Conveying Device

Feature 1: Suitable for medium-precision, medium-frequency driving and positioning.

Feature 2: One Linear Guide is centrally configured for compact design.

For more details, click here.

click here.

Feature 1: Suitable for medium-precision, medium-frequency driving and positioning.

Feature 2: One Linear Guide is centrally configured for compact design.

For more details,

click here.

click here. Application Industries

| Medical | Smartphone | |

|  | |

| Robot | Electronic appliances | |

|  |

Related Products

| Miniature Linear Guides - Standard Blocks, Light Preload / Slight Clearance | Miniature Linear Guides - Wide Rail, Light Preload / Slight Clearance | Linear Guides for Heavy Load - Normal Clearance | ||

|  |  | ||

| Representative Model:SSEB10-55 | Representative Model:SSEBW12-200 | Representative Model:SXR24-280 |

Related Documents

For Linear Guide installation instructions,  please refer here.

please refer here.

please refer here.

please refer here.