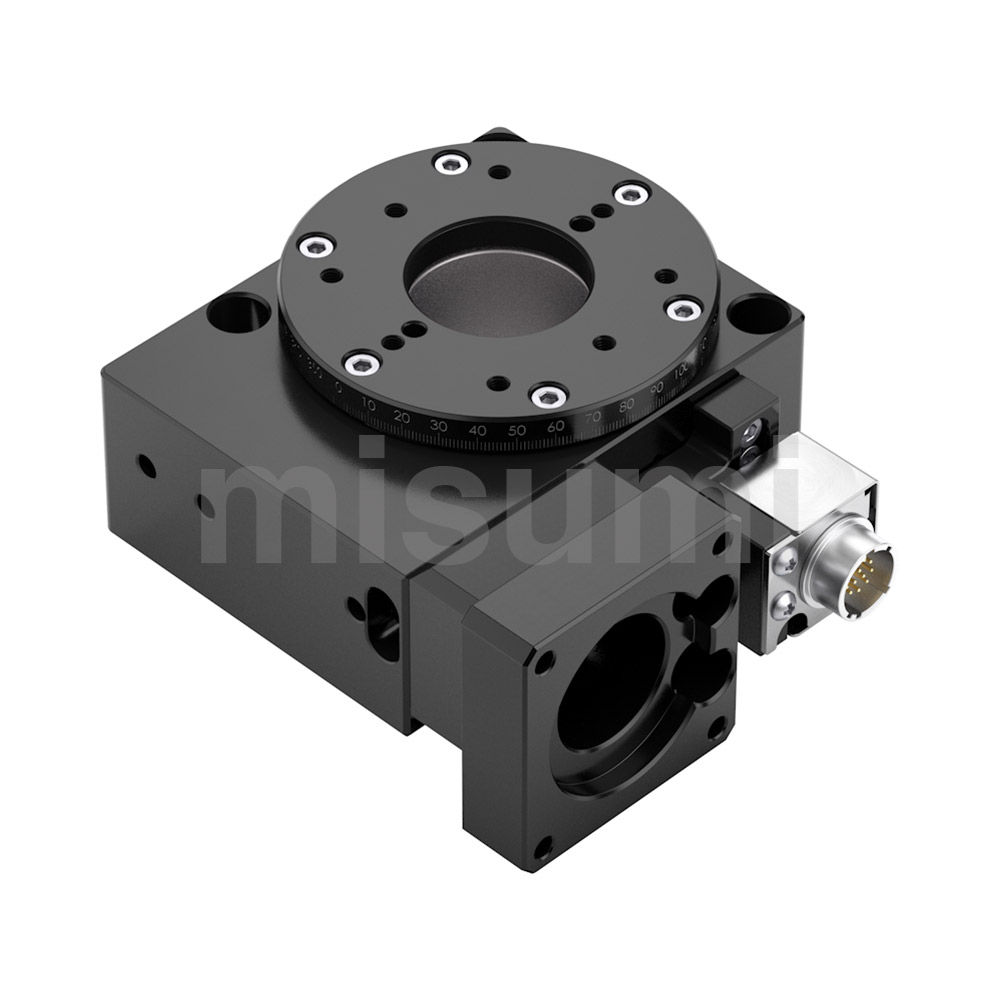

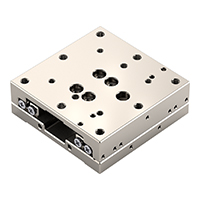

Motorized Rotary Stages Worm Gear Type, Position Repeatability ±0.05°

Caution

Product Description

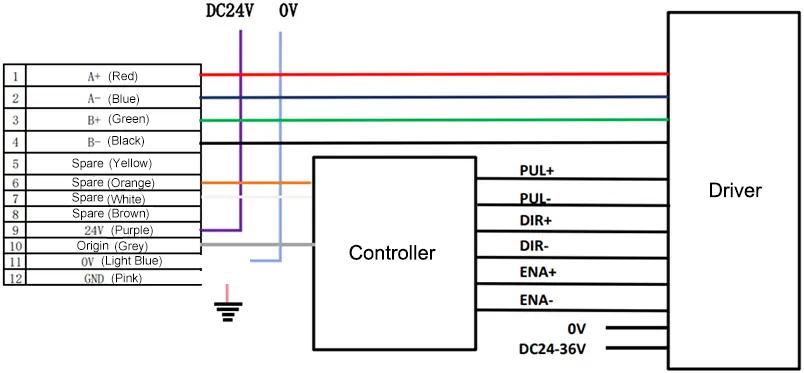

The wiring diagram for November 2024 has been updated. Please refer to the website for confirmation.

E-RMPGH40360-R-S3

E-RMPGH60360-R-S3

E-RMPGH80360-R-S3

E-RMPGH100360-R-S4

E-RMPGH120360-R-S4

Material: Aluminum alloy

Material: Aluminum alloy Surface treatment: Black anodized

Surface treatment: Black anodized| Type | Slide Table Diameter (mm) |  Cover Plate Cover PlatePosition |  Motor Motor |  Driver Driver |  Cable CableLength (m) | Mechanical Specifications | Accuracy Specifications | Sensor | ||||||||||

Type Type |  Type Type | Travel distance (mm) | Load capacity (N) | Weight (kg) | Resolution (pulses) | Maximum speed | Unidirectional positioning accuracy | Repeat positioning accuracy | Non-effective movement | Parallelism | Limit sensor | Origin sensor (ORG1) | ||||||

| E-RMPGH | Rotary axis | 40360 | ⌀39 | L | Blank (with standard stepper motor) S1 (With servo bracket PCD=45) S2 (with servo bracket PCD=46) S3 (With 28-frame stepper motor mounting bracket) S4 (With 42-frame stepper motor mounting bracket) | A (single-axis pulse driver) N (no driver) E (EtherCat bus driver) | 2 (2-meter cable) 4 (4-meter cable) | 360° | 29.4 | 0.5 | 0.015° | 30°/sec | 0.1° | ±0.05° | 0.1° | 50 µm | No | Yes |

| R | ||||||||||||||||||

| 60360 | ⌀60 | L | 39.2 | 0.9 | 0.01° | 20°/sec | ||||||||||||

| R | ||||||||||||||||||

| 80360 | ⌀79 | R | 1.1 | |||||||||||||||

| 100360 | ⌀99 | R | 196 | 1.9 | 0.015° | 30°/sec | ||||||||||||

| 120360 | ⌀119 | R | 2.2 | |||||||||||||||

Driver: The pulse driver model used in this series is E-DR42C.

Driver: The pulse driver model used in this series is E-DR42C. Bus driver brand and model: Leadshine DM3C-EC522.

Bus driver brand and model: Leadshine DM3C-EC522. Cable: The cable models used in this series are HRS12-2M (2-meter cable) / HRS12-4M (4-meter cable).

Cable: The cable models used in this series are HRS12-2M (2-meter cable) / HRS12-4M (4-meter cable). Servo motor mounting bracket type. Recommended motor brands: Yaskawa, Inovance, Mitsubishi, Leadshine, Moons, etc. Recommended power: 50W, 100W. Please carefully check the motor mounting dimensions.

Servo motor mounting bracket type. Recommended motor brands: Yaskawa, Inovance, Mitsubishi, Leadshine, Moons, etc. Recommended power: 50W, 100W. Please carefully check the motor mounting dimensions. Motors S1 and S2 are not suitable for model 40360. Motor S3 is only suitable for models E-RMPGH40360, E-RMPGH60360, E-RMPGH80360, and motor S4 is only suitable for models E-RMPGH100360E-RMPGH120360.

Motors S1 and S2 are not suitable for model 40360. Motor S3 is only suitable for models E-RMPGH40360, E-RMPGH60360, E-RMPGH80360, and motor S4 is only suitable for models E-RMPGH100360E-RMPGH120360. ■ General specifications

| E-RMPGH40360 | E-RMPGH60360 | E-RMPGH80360 | E-RMPGH100360 | E-RMPGH120360 | ||

| Reduction ratio | 1/120 | 1/180 | 1/180 | 1/120 | 1/120 | |

| Bearing | Deep groove ball bearing | |||||

| Motor | Type | 2-phase standard stepper motor 1.3 A/phase | 2-phase high torque stepper motor 1.3 A/phase | 2-phase standard stepper motor 2.0 A/phase | ||

| Step angle | 1.8° | |||||

| Driver | Power supply voltage | 24 to 36 V DC | ||||

| Output current | 0.3 A to 2.2 A/phase (peak) | |||||

| Pulse signal voltage | 5VDC | |||||

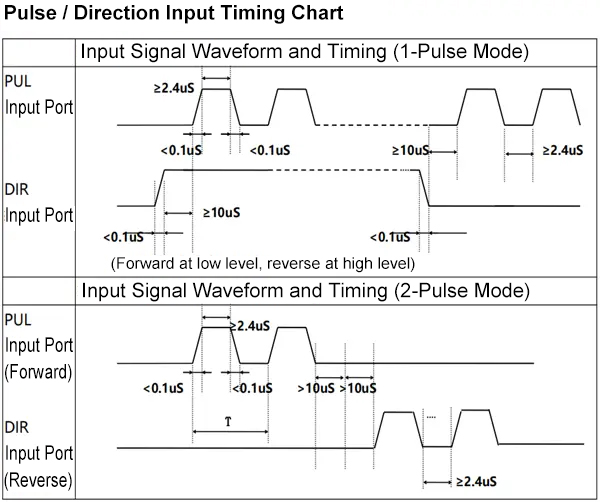

| Pulse input mode | Pulse + direction or dual pulse | |||||

| Microstep settings | 200 to 25600 | |||||

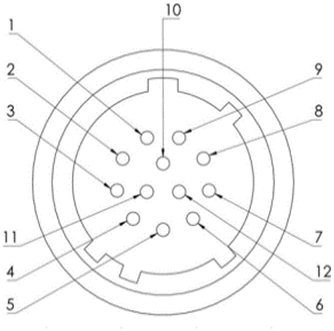

| Connector | Type | HR10A-10R-12P (Hirose) | ||||

| Receiver side type | HR10A-10P-12S (Hirose) | |||||

| Sensor board | Power supply voltage | 24 V DC ±10% | ||||

| Sensor type | Miniature photo sensor RPI-0125 (ROHM) | |||||

| Control output | NPN open collector output | |||||

| Output logic | When detected (light blocked): output transistor OFF (not conducting) | |||||

■ Connector pin arrangement

■ Timing diagram

Pulse driver

Feature 2: The body surface is treated with black anodizing, which effectively prevents light reflection, especially useful in optical applications.

Feature 3: Additional positioning holes on the slide table surface allow for quick assembly and disassembly.

Feature 4: 360-degree rotation, suitable for wide-angle positioning and rotary slide tables that require continuous 360-degree rotation.

■ Slide Table Operating Environment

Operating environment: 10 to 50°C, 20 to 70% RH (non-condensing)

Recommended environment: 22±5°C, 20 to 70% RH (non-condensing)

Please avoid using the slide table in the following environments

(1) Dusty environments (especially metal powder)

(2) Environments with direct sunlight or heat radiation

(3) Near fire sources

(4) Environments with corrosive or flammable gases

(5) Environments with splashing water or oil

(6) Environments with strong vibration or impact

(7) Environments with organic solvents or high salt content

■ Maintenance of the Slide Table

There is no unified regular maintenance standard due to differences in grease types and operating environments. Depending on the drive conditions and the type of guide rail, please be sure to check the grease at least once a month.

| Electronics/Home Appliances | Automotive | Medical | ||

|  |  | ||

| Smartphones | Semiconductors | Lithium batteries | ||

|  |  |

Compatible drivers support dual pulse and pulse + direction control. For installation dimensions and user manual, refer to: E-DR42C

■ Bus Driver

For installation dimensions and user manual of the driver, refer to Leadshine DM3C-EC522

| Direction of movement | ||||||

| X axis | Rotary axis | Goniometer | Z axis | Multi-axis combination | ||

| Guide mechanism |  Linear ball | Thin type, repeatability ±1.5µ Standard type, repeatability ±1µ Standard type, repeatability ±1.5µ With recirculator, standard type, repeatability ±1.5µ/±2µ With recirculator, standard type, repeatability ±1µ With recirculator cover, standard type, repeatability ±1µ Repeatability ±5µ | — | — | Lifting type Repeatability ±5µ Repeatability ±5µ | Repeatability ±5µ |

Crossed roller | Repeatability ±1.5µ Repeatability ±1µ | — | Repeatability ±0.006° Repeatability ±0.01° | Repeatability ±1µ | Repeatability ±0.01° | |

| Displacement mechanism |  Ball screw | — | Repeat positioning accuracy ±0.005° Repeat positioning accuracy ±0.01° | — | — | — |

Worm gear and worm | — | Repeatability ±0.05° Repeatability ±0.08° | — | — | — | |