Area Sensor, General Purpose

Caution

- [Important Notice]

· This product is Area Sensor, no certificate of safety standard be provided.

· Using this area sensor as safety equipment for Press machine, Shearing machine, dangerous part of automation machine to protect human's hand and body is NOT recommended. - Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

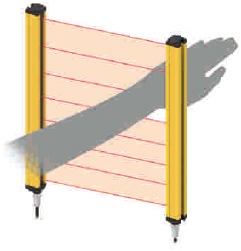

Product Description

Economy-series general-purpose area sensor has a compact appearance and is suitable for the protection of various automation equipment.It also has the advantages of high precision and long shooting distance.

This safety light curtain complies with IEC61508 SIL2 safety level standards.

The output adopts an independent dual-loop output control method and has safety self-inspection and mutual inspection functions.

Small appearance size, cross-sectional size 35*27mm. It adopts an independent dual-loop output control method, which is safe and reliable.

Short response time, the fastest response time is <1ms.

Wide voltage power supply DC24±20%.

Strong anti-electromagnetic interference ability, which can effectively resist various electromagnetic interference effects of motor equipment.

It adopts line synchronization technology and has strong anti-light interference ability. It is easy to install and simple to operate.

·Uses independent dual-circuit output control for high safety and reliability

·Short response time, fastest response time <1 ms

·Wide voltage supply DC24±20%

·Strong electromagnetic interference resistance, effectively withstands various electromagnetic interferences from motor equipment

·Uses line synchronization technology, strong resistance to optical interference

·Easy installation and simple operation

| Old E-ARS20-20-N | New E-MBF3SG20-20-N | |

| Sensing height | 380mm | 380mm |

| Sensing distance | 0.1~3m | 0.1~3m |

| Optical axis pitch | 20mm | 20mm |

| Light type | - | Infrared 940nm |

| Lenses | One side | Both side |

| Light beam angle | 15 Degree | 5 Degree |

| Response time | ≤5ms | 2.5ms |

| Supply voltage | DC24V ±10% | DC24V ±20% |

| Output | NPN | NPN |

| Number of output | 1 | 2 |

| Housing protection rating | - | IP54 |

| Electrical protection | Reverse Connection Protection/Output Short Circuit Protection | |

| Operating temperature | - | -10 to 55℃(No condensation) |

| Housing material | Aluminum alloy | Aluminum alloy |

| Anti-light interference | 10000Lux | 10000Lux (angle of incidence I > 5°) |

| Connection cable | Circular Connector 0.2mm2 PVC Length 2.5m | (GX12) × 1 (2pcs) 2.5m at emitter side, 3.5m at receiver side |

| Overall compare | • Economical choice. • Suitable for normal condition • Suitable for short detection distance | • Has lens in both transmitter and receiver • Better external light resistance • Smaller light beam, reduce influence of external reflective surface • Better protection with IP54 |

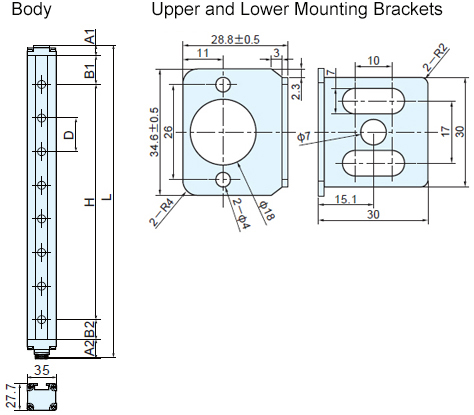

| Part number | Item Size |

| A1 | Upper end cap |

| A2 | Lower End Cover + Aviation Terminal |

| B1 | Upper Blind Zone |

| B2 | Lower Blind Spot |

| D | Shaft Spacing |

| H | Protection Height |

| L | Total Height |

When D size is 10 mm: B1 size is 5 mm; B2 size is 30 mm.

When the D dimension is 20 mm: B1 dimension is 10 mm; B2 dimension is 35 mm.

When the D dimension is 40 mm: B1 dimension is 10 mm; B2 dimension is 35 mm.

L is the total height of the area sensor: L = height of upper and lower end caps + upper and lower blind spots + protection height

H is the protection height of the area sensor: H = (number of optical axes - 1) × optical axis pitch

| Types | Optical Axis Pitch (10 mm) | Optical Axis Pitch (20 mm) | Optical Axis Pitch (40 mm) |

| Part number | E-MBF3SG10 | E-MBF3SG20 | E-MBF3SG40 |

| Item | |||

| Detection Height | 70 to 1960 mm | ||

| Casing Dimension | 35 × 27.7 mm | ||

| Detection Distance | 0 to 3 m | ||

| Optical Axis Pitch | 10/20/40 mm | ||

| Infrared Wavelength | 940 nm | ||

| Synchronization Method | Line Synchronization | ||

| Max. Power | ≤ 5W | ||

| Response Time | < 5 ms | ||

| Power Supply Voltage | 24 V DC ±20% | ||

| Safe Output (OSSD) | PNP transistor output: Load current ≤ 200 mA, residual voltage ≤ 1 V (excluding voltage drop caused by cable extension), leakage current ≤ 1 mA; NPN transistor output: Load current ≤ 200 mA, residual voltage ≤ 1 V (excluding voltage drop caused by cable extension), leakage current ≤ 1 mA. | ||

| Enclosure Protection Rating | IP 54 | ||

| Operating Temperature | -10 to 55°C (no condensation) | ||

| Storage Temperature | -20 to 70°C | ||

| Relative Humidity | 15% to 85% | ||

| Case Material | Aluminum | ||

| Light Interference Resistance | 10000Lux (Incidence Angle I > 5°) | ||

| Connection Method | (G × 12) × 1 (2 pcs) Emitter extension cable 2.5 m, receiver extension cable 3.5 m | ||

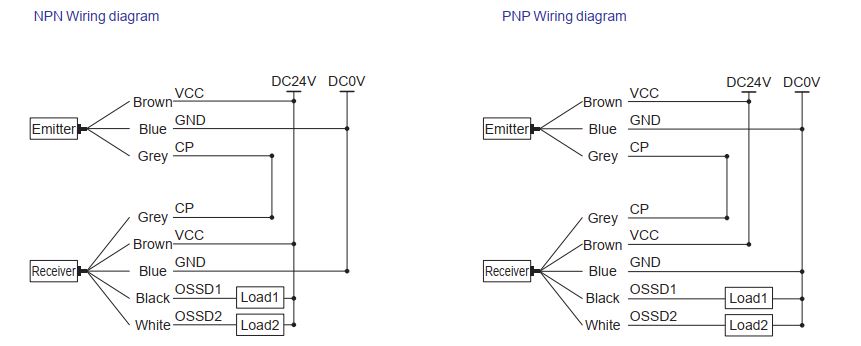

■ Output Circuit Diagram

| No. | Wire Color | Transmitter | Receiver | Wiring |

| 1 | Brown | +24 V | +24 V | Power Supply+ |

| 2 | Blue | 0V | 0V | Power Supply - |

| 3 | Grey | For Communication Use | For Communication Use | Transmitter and Receiver Interconnection |

| 4 | Black | / | NPN/PNP Output | Load Input Terminal 1 |

| 5 | White | / | NPN/PNP Output | Load Input 2 |

■ Area Sensor Operating Status

| Output Method | Area Sensor Status | Transmitter Indicator Light | Receiver Indicator Light | |

| Green Light | Green Light | Red Light | ||

| NPN NC | Optical Transmission | ○ | ○ | ● |

| Light Blocking | ○ | ● | ○ | |

| PNP NC | Optical Transmission | ○ | ○ | ● |

| Light Blocking | ○ | ● | ○ | |

| Part Number | - | Number of Optical Axes | - | Output Type | ||||

| E-MBF3SG | - | 4 | - | N |

| Part Number |  Number of Optical Axes Number of Optical Axes |  Output Type Output Type | Detection Height H (mm) | Component Dimension | Total Height L (mm) | |

Type Type |  Optical Axis Pitch D Optical Axis Pitch D | H=( -1) × -1) × | L=A1+A2+B1+B2+H | |||

| E-MBF3SG | 10 | 8 to 100 | N(NPN Output)/ P(PNP Output) | 70 to 990 | A1:14 mm, A2:20 mm, B1:5 mm, B2:30 mm | 139 to 1059 |

| 20 | 4 to 50 | 60 to 980 | A1:14 mm, A2:20 mm, B1:10 mm, B2:35 mm | 139 to 1059 | ||

| 40 | 4 to 50 | 120 to 1960 | A1:14 mm, A2:20 mm, B1:10 mm, B2:35 mm | 199 to 2039 | ||

| Type | Optical Axis Pitch | Number of Optical Axes | Output Type | Detection Height (mm) | Total height (mm) |

| D | H | L | |||

| E-MBF3SG | 10 | 8 | NPN: N PNP: P | 70 | 139 |

| 12 | 110 | 179 | |||

| 16 | 150 | 219 | |||

| 20 | 190 | 259 | |||

| 24 | 230 | 299 | |||

| 28 | 270 | 339 | |||

| 32 | 310 | 379 | |||

| 36 | 350 | 419 | |||

| 40 | 390 | 459 | |||

| 44 | 430 | 499 | |||

| 48 | 470 | 539 | |||

| 52 | 510 | 579 | |||

| 56 | 550 | 619 | |||

| 60 | 590 | 659 | |||

| 64 | 630 | 699 | |||

| 68 | 670 | 739 | |||

| 72 | 710 | 779 | |||

| 76 | 750 | 819 | |||

| 80 | 790 | 859 | |||

| 84 | 830 | 899 | |||

| 88 | 870 | 939 | |||

| 92 | 910 | 979 | |||

| 96 | 950 | 1019 | |||

| 100 | 990 | 1059 | |||

| 20 | 4 | 60 | 139 | ||

| 6 | 100 | 179 | |||

| 8 | 140 | 219 | |||

| 10 | 180 | 259 | |||

| 12 | 220 | 299 | |||

| 14 | 260 | 339 | |||

| 16 | 300 | 379 | |||

| 18 | 340 | 419 | |||

| 20 | 380 | 459 | |||

| 22 | 420 | 499 | |||

| 24 | 460 | 539 | |||

| 26 | 500 | 579 | |||

| 28 | 540 | 619 | |||

| 30 | 580 | 659 | |||

| 32 | 620 | 699 | |||

| 34 | 660 | 739 | |||

| 36 | 700 | 779 | |||

| 38 | 740 | 819 | |||

| 40 | 780 | 859 | |||

| 42 | 820 | 899 | |||

| 44 | 860 | 939 | |||

| 46 | 900 | 979 | |||

| 48 | 940 | 1019 | |||

| 50 | 980 | 1059 | |||

| 40 | 4 | 120 | 199 | ||

| 6 | 200 | 279 | |||

| 8 | 280 | 359 | |||

| 10 | 360 | 439 | |||

| 12 | 440 | 519 | |||

| 14 | 520 | 599 | |||

| 16 | 600 | 679 | |||

| 18 | 680 | 759 | |||

| 20 | 760 | 839 | |||

| 22 | 840 | 919 | |||

| 24 | 920 | 999 | |||

| 26 | 1000 | 1079 | |||

| 28 | 1080 | 1159 | |||

| 30 | 1160 | 1239 | |||

| 32 | 1240 | 1319 | |||

| 34 | 1320 | 1399 | |||

| 36 | 1400 | 1479 | |||

| 38 | 1480 | 1559 | |||

| 40 | 1560 | 1639 | |||

| 42 | 1640 | 1719 | |||

| 44 | 1720 | 1799 | |||

| 46 | 1800 | 1879 | |||

| 48 | 1880 | 1959 | |||

| 50 | 1960 | 2039 |

E-MBF3SG20-4 total height cannot be used in the calculation formula

E-MBF3SG20-4 total height cannot be used in the calculation formula Area sensor is used to detect objects, NOT suitable to the application where human safety should be secured.

Area sensor is used to detect objects, NOT suitable to the application where human safety should be secured.

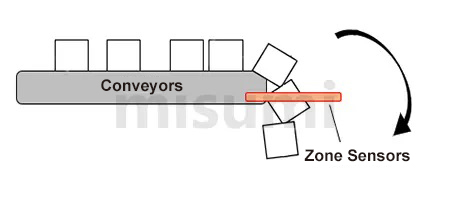

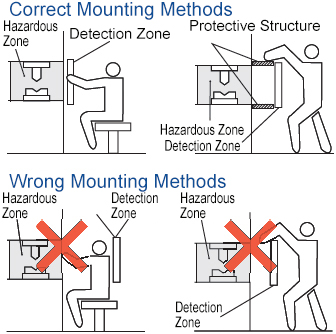

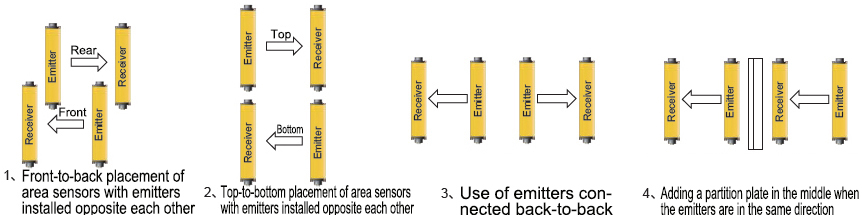

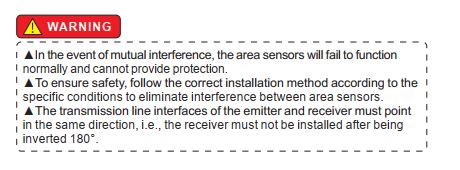

3. Precautions for Adjacent Installation

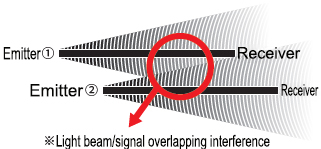

When two or more area sensor devices are installed close to each other, mutual interference between the area sensor devices can easily occur. As shown in Figure 3-1, the infrared light emitted by the transmitter unit of Product (1) may affect the receiver unit of Product (2) . This may interfere with the protective function of product (2), which means that operators may be at risk. Therefore, please install according to Figure 3-2. Avoid installing sensors for adjacent areas on the same side without a light-blocking partition, as the light emitted by the transmitter may easily reach the receiver of a neighboring set.

Figure 3-1 Diagram of Mutual Interference Between Emitter (1) and Emitter (2)

Figure 3-2 Installation diagram to prevent mutual interference between area sensors

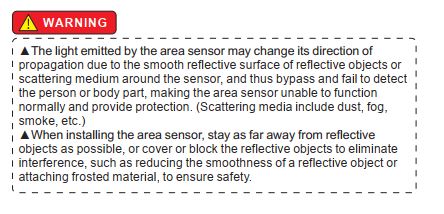

4. Correct Installation Position When There Are Reflective Objects

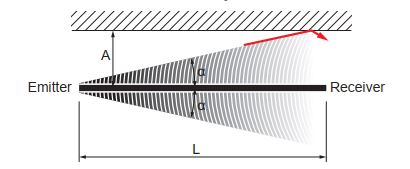

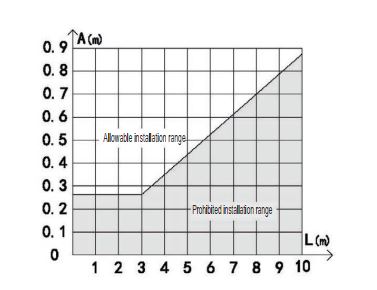

If there are objects with smooth reflective surfaces around the area sensor device, such as metal plates, floors, ceilings, workpieces, covers, partitions, glass panels, etc., the installation position of the area sensor should be more than A (m) away from the reflective surface. The value of A can be obtained by calculation formula or found in coordinate chart 4-2. As shown in Figure 4-1, the cone has an aperture angle α, which is formed between the optical axis and the light beam located at the edge of the optical cone. Where α = the aperture angle of the light beam, L = the distance between the emitter and receiver, and L

4-1 Reflective Object Interference Diagram

A (m) = L × tanα = L × 0.0875 (α = 5°)

| Protection Length L (m) | Maximum distance A (m) not available |

| 0.3 to 3 m | 0.262 m |

4-2 Coordinate Diagram of Installation Positions Where Reflective Objects Affect Area Sensors

● This product is developed/manufactured for use in industrial environments.

● Do not use outdoors.

● When this product is used to enhance human protection against hazards occurring around operating machinery, there may be regulations from relevant national or regional safety authorities. For more details, please contact the relevant department.

● When incorporating this product into specific machinery, please follow safety regulations that include proper usage methods, installation, operation, and maintenance items. Installers and responsible users are obligated to implement this product according to these items.

● This product may be damaged if subjected to excessive impact such as dropping. Please handle with care.

● Use this product only after considering possible malfunctions and implementing safety measures to prevent loss.

● Before operating this product, please confirm that its functions and performance operate normally according to the design specifications before use.

● When disposing of this product, please treat it as industrial waste.