Angular Contact Bearing, Thin Wall, Single-Row Universal Combination Type

Brand :

MISUMI

Caution

- Some Page Materials are under updating.

Product Description

Economy Series Angular Contact Ball Bearing

Product Overview

· Angular contact ball bearings are mainly used to withstand radial loads and can also withstand small axial loads.

· Angular contact ball bearings are widely used in precision CNC machine tools, high-speed grinding machines, engraving machines, high-speed spindles, RV reducers, and other industries.

· Angular contact ball bearings are widely used in precision CNC machine tools, high-speed grinding machines, engraving machines, high-speed spindles, RV reducers, and other industries.

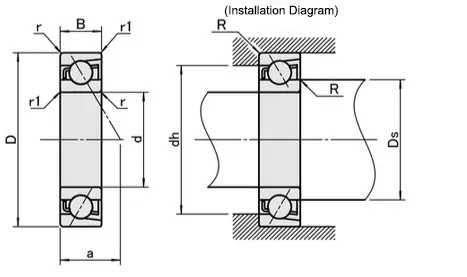

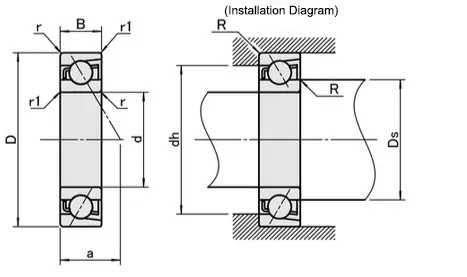

Dimensional Drawing

Economy Type Angular Contact Ball Bearing, Single Row Universal Combination Type

E-B70□□-SU

E-B72□□-SU

Product Dimensions

Product Model:

Product Model:

E-B70□□-SU

E-B72□□-SU

Material Material | Bearing Precision | Contact Angle | Vibration Class |

| Equivalent to SUJ2 | P4 Grade | 25° | V1 |

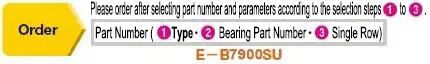

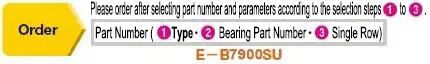

Specification Table

| Part Number | Dimensions (mm) | Rated Load (kN) | Rotational Speed Limit (rpm) | r (min) | r1 (min) | Point of Action a | Mounting Dimensions | Weight (kg) | ||||||||

Type Type |  Bearing Part Number Bearing Part Number |  Single Row Single Row | Inner Diameter d | Outer Diameter D | Width B | Cr | Cor | Grease Lubrication | Oil Lubricated | Ds (min.) | dh (max.) | R (max.) | ||||

| E-B | 7900 | SU | 10 | 22 | 6 | 2.4 | 1.0 | 63000 | 95000 | 0.3 | 0.2 | 6.8 | 12 | 20 | 0.3 | 0.01 |

| 7901 | 12 | 24 | 2.5 | 1.1 | 56000 | 85000 | 7.3 | 14 | 22 | |||||||

| 7902 | 15 | 28 | 7 | 3.7 | 1.8 | 50000 | 75000 | 8.5 | 17 | 26 | 0.02 | |||||

| 7903 | 17 | 30 | 3.9 | 2 | 45000 | 67000 | 9 | 19 | 28 | |||||||

| 7904 | 20 | 37 | 9 | 5.7 | 3.0 | 38000 | 56000 | 11.2 | 22 | 35 | 0.04 | |||||

| 7905 | 25 | 42 | 6.3 | 3.8 | 32000 | 48000 | 12.4 | 27 | 40 | |||||||

| 7906 | 30 | 47 | 6.7 | 4.3 | 26000 | 40000 | 13.6 | 32 | 45 | 0.05 | ||||||

| 7907 | 35 | 55 | 10 | 9.2 | 6.2 | 22000 | 36000 | 0.6 | 0.3 | 15.6 | 38.2 | 51.8 | 0.6 | 0.07 | ||

| 7908 | 40 | 62 | 12 | 11.7 | 8.0 | 18000 | 30000 | 18 | 43.2 | 58.8 | 0.11 | |||||

| 7909 | 45 | 68 | 12.4 | 9 | 17000 | 28000 | 19.3 | 66.6 | 64.8 | 0.126 | ||||||

| 7910 | 50 | 72 | 12.7 | 9.8 | 16000 | 26000 | 20.3 | 53.2 | 68.8 | 0.129 | ||||||

| 7911 | 55 | 80 | 13 | 18.2 | 13.7 | 15000 | 24000 | 1.1 | 22.4 | 59.6 | 75.4 | 1.1 | 0.174 | |||

| 7912 | 60 | 85 | 18.6 | 14.6 | 14000 | 22000 | 23.5 | 64.6 | 80.4 | 0.187 | ||||||

| 7913 | 65 | 90 | 19.5 | 16 | 13000 | 20000 | 24.7 | 69.6 | 85.4 | 0.2 | ||||||

| 7914 | 70 | 100 | 16 | 32.5 | 32.5 | 11000 | 18000 | 27.9 | 74.6 | 95.4 | 0.34 | |||||

| 7915 | 75 | 105 | 33.8 | 35.5 | 10000 | 17000 | 29.1 | 79.6 | 100 | 0.36 | ||||||

| 7916 | 80 | 110 | 34.5 | 36.5 | 9500 | 16000 | 30.2 | 84.6 | 105 | 0.38 | ||||||

| 7917 | 85 | 120 | 18 | 43.6 | 45.5 | 9000 | 15000 | 0.6 | 33 | 91 | 114 | 0.53 | ||||

| 7918 | 90 | 125 | 44.2 | 48.0 | 8500 | 14000 | 34.2 | 96 | 119 | 0.56 | ||||||

| 7919 | 95 | 130 | 46.2 | 52 | 14000 | 35.3 | 101 | 124 | 0.582 | |||||||

| 7920 | 100 | 140 | 20 | 57.2 | 63.0 | 8000 | 13000 | 38.1 | 106 | 134 | 0.79 | |||||

| 7921 | 105 | 145 | 57.2 | 65.5 | 7500 | 12000 | 39.3 | 111 | 139 | 0.81 | ||||||

| 7922 | 110 | 150 | 58.5 | 68.0 | 7500 | 40.4 | 116 | 144 | 0.84 | |||||||

| 7924 | 120 | 165 | 22 | 72.8 | 86.5 | 7000 | 11000 | 44.4 | 126 | 159 | 1.15 | |||||

| 7926 | 130 | 180 | 24 | 87.1 | 102.0 | 6700 | 10000 | 1.5 | 48.3 | 137 | 173 | 1.5 | 1.52 | |||

Product Features

· The product's precision reaches P4 grade; the precision grade directly affects its operating condition and service life.

· Any two universal matching P4 grade angular contact ball bearings can be combined in different sets, making assembly convenient.

· Any two universal matching P4 grade angular contact ball bearings can be combined in different sets, making assembly convenient.

Precautions

When the precision of the shaft and bearing housing is poor, the bearing will be affected, and its due performance will not be exerted. For example, the poor precision of the mounting part with the bearing will cause relative inclination of the inner and outer rings. At this time, besides the bearing load, the edge load will be increased additionally, which will shorten the fatigue life of the bearing, and even more seriously, it will lead to damage such as cage breakage and sticking.

Please use the following special mounting tool for installation and removal

Please use the following special mounting tool for installation and removal

| Bearing heater | |

| Proper installation of the bearing heater can guarantee a long life of the bearing. Rolling bearings are reliable mechanical components with long service life if they are installed and maintained correctly. After the induction heater is used for heating, the bearing expands outward in the cylindrical direction, which can avoid the damage during installation. Induction heater is one of the most scientific heating methods, which does not need preheating, and can be heated to 110℃ in a few seconds or minutes depending on the weight of bearings, without damaging the prior lubrication |

| Bearing puller | |

| When the installation state of the bearing is in the following situations, the special puller can be used for disassembly. (a) Shaft shape: cylindrical shaft, Inner diameter shape of bearing inner ring: cylindrical hole. (b) Shaft shape: cylindrical shaft, inner diameter shape of bearing inner ring with tight bushing: tapered hole. (c) Shaft shape: tapered shaft, Inner diameter shape of bearing inner ring: tapered hole. In either state, the lock nut of the shaft (or the lock nut of the tight bushing) must be released during disassembly, and the lock nut must be placed in a loose state. |

Example of Use