Bushings for Locating Pins Shouldered, Configurable

Brand :

MISUMI

Caution

Product Description

Product Overview

The fixture bushing is a mechanical positioning part that is used in conjunction with a positioning pin to achieve a guiding effect, in which the shouldered, standard type is widely used, and the shoulder contacts the workpiece, effectively controlling the installation position. And it can effectively prevent the rapid wear of the workpiece.

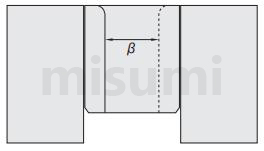

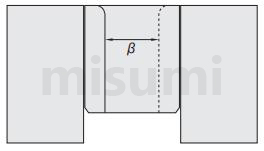

Dimensional Drawing

The p7 type has a larger inner diameter shrinkage rate compared to the m7 type, so be careful when machining holes. (See Precautions for the inner diameter change after press-fit)

The p7 type has a larger inner diameter shrinkage rate compared to the m7 type, so be careful when machining holes. (See Precautions for the inner diameter change after press-fit)Specifications Overview

■Material Specification Table

If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating.

If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating.

| Type |  Material Material |  Surface Treatment Surface Treatment |  Hardness Hardness | |

| p7 | m7 | |||

| E-JBHFP | E-JBHF | Equivalent to 9CrWMn (Alloy Tool Steel or Bearing Steel) | - | 55HRC~ |

| E-JBHFBP | E-JBHFB | Equivalent to 9CrWMn (Alloy Tool Steel or Bearing Steel) | Ferroferric Oxide Protective Film | 55HRC~ |

| E-JBHFMP | E-JBHFM | Equivalent to 9CrWMn (Alloy Tool Steel or Bearing Steel) | Electroless Nickel Plating | 55HRC~ |

| E-JBHFSP | E-JBHFS | Austenitic stainless steel | - | - |

| E-JBHFCP | E-JBHFC | Martensitic stainless steel | - | 45HRC~ |

If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating.

If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating.Specification Table

| Part Number |  P P0.01mm increments |  L L0.1mm increments | Wall Thickness(N) | H | T | |||

Type Type |  D D | D Tolerance | ||||||

| p7 | m7 | |||||||

| (p7) E-JBHFP E-JBHFBP E-JBHFMP E-JBHFSP E-JBHFCP (m7) E-JBHF E-JBHFB E-JBHFM E-JBHFS E-JBHFC | 5 | +0.024 +0.012 | +0.021 +0.006 | 2.20~ 2.50 | 3.0~ 3.5 | 1.25~1.50 | 9 | 2.5 |

| 7 | +0.030 +0.015 | +0.021 +0.006 | 2.20~ 3.50 | 3.0~ 6.0 | 1.75~2.50 | 11 | ||

| 8 | 3.00~ 4.50 | 3.0~10.0 | 12 | 3 | ||||

| 10 | 4.00~ 6.50 | 3.0~15.0 | 1.75~3.00 | 14 | ||||

| 12 | +0.036 +0.018 | +0.025 +0.007 | 6.00~ 8.50 | 16 | 4 | |||

| 15 | 8.00~10.50 | 10.0~35.0 | 2.25~3.50 | 19 | ||||

| 18 | 10.00~12.50 | 2.75~4.00 | 22 | |||||

| 20 | +0.043 +0.022 | +0.029 +0.008 | 12.00~13.50 | 3.25~4.00 | 26 | 5 | ||

| 22 | 12.00~13.50 | 4.25~5.00 | ||||||

| 25 | 13.00~15.50 | 4.75~6.00 | 30 | |||||

| 26 | 15.00~16.50 | 4.75~5.50 | ||||||

| 30 | 16.00~20.50 | 12.0~50.0 | 4.75~7.00 | 35 | 6 | |||

| 35 | +0.051 +0.026 | +0.034 +0.009 | 20.00~25.00 | 5.00~7.50 | 40 | |||

When P≤3.59, L+T≤P×2.5

When P≤3.59, L+T≤P×2.5 When P≥3.60, L+T≤P×3.0

When P≥3.60, L+T≤P×3.0Product Features

Feature 1: fixture bushing, shouldered press-fit type, can support the body through the shoulder, and is suitable for applications where it is difficult to adjust the hole depth, press-fit installation, the tolerance of the O.D. press-fit dimension can be specified: p7, m7.

Feature 2: low cost and a rich variety of types, stock models can be shipped on the same day.

Feature 3: electroless nickel plated type can effectively prevent rust.

Feature 4: Optional material: iron (alloy tool steel or bearing steel); austenitic stainless steel (martensitic stainless steel).

Feature 5: Some models are ordered in a large quantity of 500 pcs, and can be shipped within 7 days, For details, consult by CS@misumi.sh.cn.

Feature 2: low cost and a rich variety of types, stock models can be shipped on the same day.

Feature 3: electroless nickel plated type can effectively prevent rust.

Feature 4: Optional material: iron (alloy tool steel or bearing steel); austenitic stainless steel (martensitic stainless steel).

Feature 5: Some models are ordered in a large quantity of 500 pcs, and can be shipped within 7 days, For details, consult by CS@misumi.sh.cn.

Precautions

①Dimensional tolerance and fit parameter table For details, click  Dimensional Tolerance Fit Table

Dimensional Tolerance Fit Table

②Change in inner diameter of the fixture bushing during press-fit

■Change in inner diameter of the fixture bushing during press-fit

The fixture bushing shrinks when press-fitted.

The shrinkage rate varies depending on material of mounting part and D dimension tolerance of bushing.

【Example of Shrinkage during Press-Fit】

①Before press-fit

②After press-fit ③Reference table for common dimensions without indicated tolerance (medium accuracy m) For details, click

③Reference table for common dimensions without indicated tolerance (medium accuracy m) For details, click  Table of Dimensions Without Indicated Tolerance

Table of Dimensions Without Indicated Tolerance

Dimensional Tolerance Fit Table

Dimensional Tolerance Fit Table②Change in inner diameter of the fixture bushing during press-fit

■Change in inner diameter of the fixture bushing during press-fit

The fixture bushing shrinks when press-fitted.

The shrinkage rate varies depending on material of mounting part and D dimension tolerance of bushing.

【Example of Shrinkage during Press-Fit】

①Before press-fit

②After press-fit

βDimension (when mounting hole is H7)

| D Dimension Tolerance | ||

| Mounting Material | m7 | p7 |

| Steel | αX99.93% | αX99.90% |

| Aluminum Alloy | αX99.96% | αX99.93% |

Table of Dimensions Without Indicated Tolerance

Table of Dimensions Without Indicated ToleranceExample of Use

Example introduction: shouldered bushing for positioning pin in pick and place mechanism

Design summary:

①An example of using a swing cylinder to achieve linear and rotary motion through pneumatic drive, and moving a small substrate through a suction cup.

②In the case of a long pin, if the air vent is not provided, the pin and bushing are not easy to pull out. It is necessary to provide a air vent on the bushing side or the positioning pin side.

Intended use of fixture bushing:

The axial structure of the swing cylinder can ensure positioning accuracy while saving space through the coordination of positioning pins/shouldered bushings.

For more information, please refer to Example Details

Example Details

Design summary:

①An example of using a swing cylinder to achieve linear and rotary motion through pneumatic drive, and moving a small substrate through a suction cup.

②In the case of a long pin, if the air vent is not provided, the pin and bushing are not easy to pull out. It is necessary to provide a air vent on the bushing side or the positioning pin side.

Intended use of fixture bushing:

The axial structure of the swing cylinder can ensure positioning accuracy while saving space through the coordination of positioning pins/shouldered bushings.

For more information, please refer to

Example Details

Example DetailsApplication Industries

| Lithium battery | Smart Phones | Electronic & Electrical | ||

|  |  | ||

| Semiconductor | Medical | Food | ||

|  |  |

Related Products

| Locating Pins Large Head, Tapered, Press Fit, Standard | Fixture Bushings Straight, Standard | Small Diameter Locating Pins Straight | ||

|  |  | ||

| Representative model: E-JPBB6-10 | Recommended model: E-JBA12-10 | Recommended model: E-SPKS-D1-L5 | ||

| Advantages: suitable for various working conditions, widely used | Advantages: easy to install, rich in specifications | Advantages: suitable for use in confined space |

Related Documents

①Positioning technology reference information Click  Positioning Technology

Positioning Technology

②Surface treatment related anti-rust ability salt spray test reference Click Anti-rust Reference for Metal

Anti-rust Reference for Metal

Positioning Technology

Positioning Technology②Surface treatment related anti-rust ability salt spray test reference Click

Anti-rust Reference for Metal

Anti-rust Reference for Metal