Rotary Shafts Retaining Ring Groove on Both Ends with Keyway

Brand :

MISUMI

Caution

Product Description

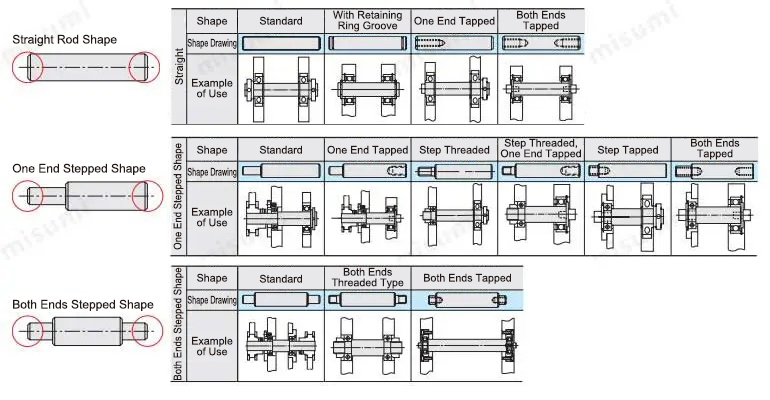

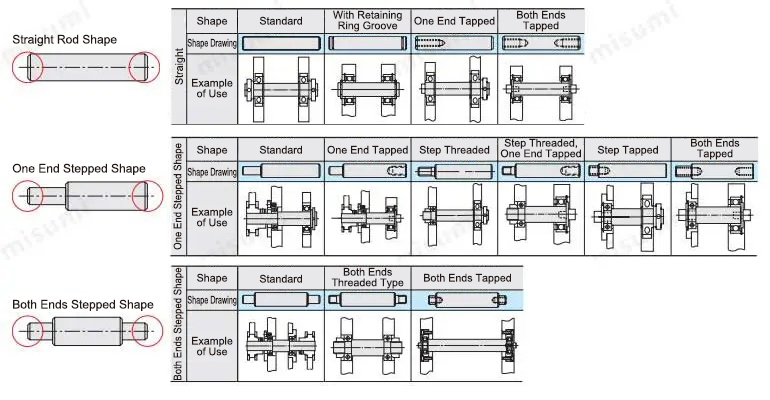

Product Overview

Rotary shaft is a high precision shaft product, which can be used in combination with bearing, roller, pulley or other bushing products to realize the function of transmitting power and conveying objects. In addition to excellent dimensional and geometric tolerances, it offers a variety of alterations.

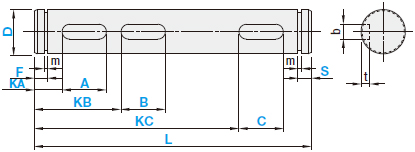

Dimensional Drawing

Specifications Overview

| Type | D Tolerance |  Material Material |  Surface Treatment Surface Treatment | D | L | |

| Standard | With Retaining Ring | |||||

| E-SFHKRR | E-SFHKRRA | h8 (Grinding Rod) | General structural steel or carbon steel | Ferroferric Oxide Protective Film | 6~50 | 15~1000 |

| E-PSFHKRR | E-PSFHKRRA | Electroless Nickel Plating | ||||

| E-SSFHKRR | E-SSFHKRRA | Austenitic stainless steel | - | |||

| E-SFGKRR | E-SFGKRRA | g7 (Grinding Rod) | General structural steel or carbon steel | Ferroferric Oxide Protective Film | ||

| E-PSFGKRR | E-PSFGKRRA | Electroless Nickel Plating | ||||

| E-SSFGKRR | E-SSFGKRRA | Austenitic stainless steel | - | |||

If there are requirements for rust prevention, give priority to the products with surface treatment of electroless nickel plating and products made of austenitic stainless steel. Please click

If there are requirements for rust prevention, give priority to the products with surface treatment of electroless nickel plating and products made of austenitic stainless steel. Please click  Anti-Rust Method

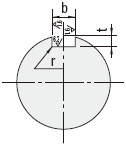

Anti-Rust Method■Detailed dimensions of the keyway

| Shaft Dia. | b | t | r | ||

| Reference Dimension | Tolerance (N9) | Reference Dimension | Tolerance | |||

| 6 | 2 | -0.004 -0029 | 1.2 | +0.1 0 | 0.08~0.16 | |

| 8·10 | 3 | 1.8 | ||||

| 12 | 4 | 0 -0.03 | 2.5 | |||

| 13~17 | 5 | 3.0 | 0.16~0.25 | |||

| 18~22 | 6 | 3.5 | ||||

| 25·30 | 8 | 0 -0.036 | 4.0 | +0.2 0 | ||

| 35 | 10 | 5.0 | 0.25~0.4 | |||

| 40 | 12 | 0 -0.043 | 5.0 | |||

| 50 | 14 | 5.5 | ||||

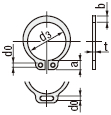

| Retaining Ring Dimensions (Material Stainless Steel) | Retaining Ring | ||||||||

| d | D | H | t | ||||||

| Tolerance | Tolerance | Tolerance | Tolerance | ||||||

| NETWS5 | 5 | 0 -0.12 | 11 | ±0.2 | 4.3 | 0 -0.30 | 0.6 | ±0.04 |

| NETWS7 | 7 | 0 -0.15 | 14 | 6.1 | 0 -0.35 | 0.8 | |||

| Retaining Ring Dimensions (Material Stainless Steel) | Retaining Ring | |||||||

| d3 | t | b (approx.) | a (approx.) | d0(Min.) | ||||

| Tolerance | Tolerance | |||||||

| STWS10 | 9.3 | ±0.15 | 1 | ±0.05 | 1.6 | 3 | 1.2 |

| STWS12 | 11.1 | ±0.18 | 1.8 | 3.2 | 1.5 | |||

| STWS15 | 13.8 | 2.2 | 3.5 | 1.7 | ||||

| STWS17 | 15.7 | 3.7 | ||||||

| STWS20 | 18.5 | ±0.2 | 1.2 | ±0.06 | 2.7 | 3.9 | 2 | |

| STWS25 | 23.2 | 3.1 | 4.3 | |||||

| STWS30 | 27.9 | 1.5 | 3.5 | 4.8 | ||||

Specification Table

h8 (Grinding Rod)

g7 (Grinding Rod)

| Part Number |  L L0.1mm increments |  F・ F・ S S1mm increments | Keyway① | Keyway② | Keyway③ | Retaining ring model 2 accessory retaining rings (Applicable to Shafts with Retaining Rings only) | |||

Type Type |  Dh8 Dh8 |  KA・ KA・ A A |  KB・ KB・ B B |  KC・ KC・ C C | |||||

| Standard | With Retaining Ring | Tolerance | 1mm increments | ||||||

| E-SFHKRR E-PSFHKRR E-SSFHKRR | E-SFHKRRA E-PSFHKRRA E-SSFHKRRA | 6 | 0 -0.018 | 15.0~400.0 | 2≤F・S<L/2 | KA+A≤L-S KA≥F b≤A≤100 | KB+B≤L-S KB≥KA+A b≤B≤100 | KC+C≤L-S KC≥KB+B b≤C≤100 | NETWS5 |

| 8 | 0 -0.022 | 15.0~500.0 | 3≤F・S<L/2 | NETWS7 | |||||

| 10 | 15.0~600.0 | STWS10 | |||||||

| 12 | 0 -0.027 | 15.0~700.0 | 4≤F・S<L/2 | STWS12 | |||||

| 15 | 15.0~800.0 | STWS15 | |||||||

| 17 | 30.0~900.0 | STWS17 | |||||||

| 20 | 0 -0.033 | 30.0~1000.0 | STWS20 | ||||||

| 25 | 50.0~1000.0 | 5≤F・S<L/2 | STWS25 | ||||||

| 30 | 60.0~1000.0 | STWS30 | |||||||

| 35 | 0 -0.039 | 70.0~1000.0 | STWS35 | ||||||

| 40 | 80.0~1000.0 | STWS40 | |||||||

| 50 | 100.0~1000.0 | STWS50 | |||||||

g7 (Grinding Rod)

| Part Number |  L L0.1mm increments |  F・ F・ S S1mm increments | Keyway① | Keyway② | Keyway③ | Retaining ring model 2 accessory retaining rings (Applicable to Shafts with Retaining Rings only) | ||||

Type Type |  Dg7 Dg7 |  KA・ KA・ A A |  KB・ KB・ B B |  KC・ KC・ C C | ||||||

| Standard | With Retaining Ring | Tolerance | 1mm increments | |||||||

| E-SSFGKRR E-PSFGKRR E-SSFGKRR | E-SFGKRRA E-PSFGKRRA E-SSFGKRRA | 6 | 0.004 -0.016 | 15.0~400.0 | 2≤F・S<L/2 | KA+A≤L-S KA≥F b≤A≤100 | KB+B≤L-S KB≥KA+A b≤B≤100 | KC+C≤L-S KC≥KB+B b≤C≤100 | NETWS5 | |

| 8 | -0.005 -0.020 | 15.0~500.0 | 3≤F・S<L/2 | NETWS7 | ||||||

| 10 | 15.0~600.0 | STWS10 | ||||||||

| 12 | -0.006 -0.024 | 15.0~700.0 | 4≤F・S<L/2 | STWS12 | ||||||

| 13 | 15.0~700.0 | STWS13 | ||||||||

| 15 | 15.0~800.0 | STWS15 | ||||||||

| 16 | 15.0~900.0 | STWS16 | ||||||||

| 17 | 30.0~900.0 | STWS17 | ||||||||

| 18 | 30.0~900.0 | STWS18 | ||||||||

| 20 | -0.007 -0.028 | 30.0~1000.0 | STWS20 | |||||||

| 22 | 40.0~1000.0 | STWS22 | ||||||||

| 25 | 50.0~1000.0 | 5≤F・S<L/2 | STWS25 | |||||||

| 30 | 60.0~1000.0 | STWS30 | ||||||||

| 35 | -0.009 -0.034 | 70.0~1000.0 | STWS35 | |||||||

| 40 | 80.0~1000.0 | STWS40 | ||||||||

| 50 | 100.0~1000.0 | STWS50 | ||||||||

Product Features

Feature 1: Extensively applied in various precision equipment thanks to high precision dimensional tolerance and geometric tolerance.

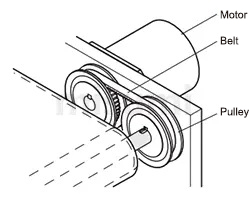

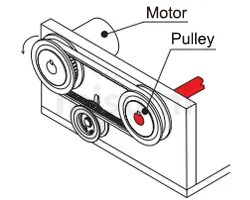

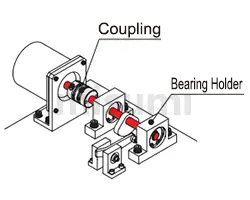

Feature 2: The shaft is intended for rotating purposes such as transmitting power and conveying objects, and used in combination with bearing, roller and timing pulley.

Feature 3: A variety of O.D. tolerances and alterations are available to accommodate different environments.

Feature 4: The product has excellent anti-corrosion performance due to the surface treatment of electroless nickel plating and the use of austenitic stainless steel as the body material.

Feature 2: The shaft is intended for rotating purposes such as transmitting power and conveying objects, and used in combination with bearing, roller and timing pulley.

Feature 3: A variety of O.D. tolerances and alterations are available to accommodate different environments.

Feature 4: The product has excellent anti-corrosion performance due to the surface treatment of electroless nickel plating and the use of austenitic stainless steel as the body material.

Usage Method

| Example of Use |  |  |  |

| Recommended Applications | Flat belt roller transfer mechanism It is connected to the roller to drive the flat belt to transport objects. | Timing pulley rotating mechanism It is connected to the timing pulley as a driven shaft to realize the function of reverse transmission. | Bearing and coupling rotating mechanism It is connected to the bearing and coupling to realize the function of forward transmission. |

Precautions

Rotary shaft selection method

STEP① Select the bearing support method

● Shaft end shape ~Please select tapped or retaining ring groove, etc. according to the fixing method~

STEP① Select the bearing support method

● Shaft end shape ~Please select tapped or retaining ring groove, etc. according to the fixing method~

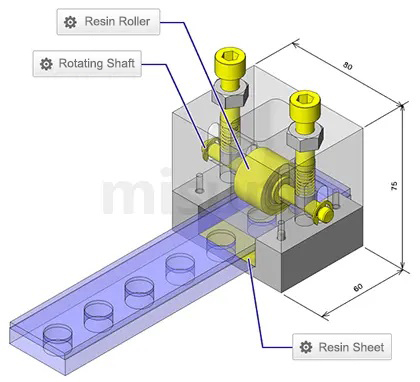

Example of Use

Equipment name: Embedded fixture

Function description:

It is an embedded assembly fixture that can be embedded into rubber workpiece and aluminum workpiece, embedding the rubber convex part into the concave part of another workpiece. Load can be adjusted with bolt and compressed by roller.

Functions of rotary shafts in the mechanism

①The rotary shaft is used as a tightening connector in the mechanism, bearing the pressure applied by the spring, and connected to roller for compressing the workpiece.

②Excellent roundness and linearity, allowing the assembly fixture to apply force evenly, thereby improving overall stability of the tooling.

For details of reference, please click Embedded Fixture.

Embedded Fixture.

Function description:

It is an embedded assembly fixture that can be embedded into rubber workpiece and aluminum workpiece, embedding the rubber convex part into the concave part of another workpiece. Load can be adjusted with bolt and compressed by roller.

Functions of rotary shafts in the mechanism

①The rotary shaft is used as a tightening connector in the mechanism, bearing the pressure applied by the spring, and connected to roller for compressing the workpiece.

②Excellent roundness and linearity, allowing the assembly fixture to apply force evenly, thereby improving overall stability of the tooling.

For details of reference, please click

Embedded Fixture.

Embedded Fixture.Application Industries

| Medical | Semiconductor | Electronic & Electrical | ||

|  |  | ||

| Smart Phones | Food | Automotive | ||

|  |  |

Related Products

| Linear Bushing Standard Type Straight Type | Bearings With Housings T-Shaped | Shaft Collars (Clamp) | ||

|  |  | ||

| Typical Model: LMU6 | Representative model: BGHFS6000ZZ-30 | Representative model: PSCS10-10 | ||

| Advantages: High quality, affordable price, short delivery time | Advantages: Full range, high precision and quality | Advantages: Matching shaft products, full range |

Related Documents