Jaw Couplings Clamping Type

Caution

Product Description

Jaw Couplings are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Shaft Hole Diameter Minimum/Maximum (mm.): 4 and 80

● Outside Diameter Minimum/Maximum (mm.): 4 and 80

● Overall Length Minimum/Maximum (mm.) : 25 and 160

● Material :

Hub - Aluminum Alloy

Spacer - Polyurethane

[Application]

Jaw Couplings are commonly used in various applications in factory automation systems

・The resin adjustment ring can alleviate the inertial load impact during start and stop.

・Flexible Shaft Couplings is Easy to disassemble and assemble.

・Recommended for stepper motors and general-purpose motors.

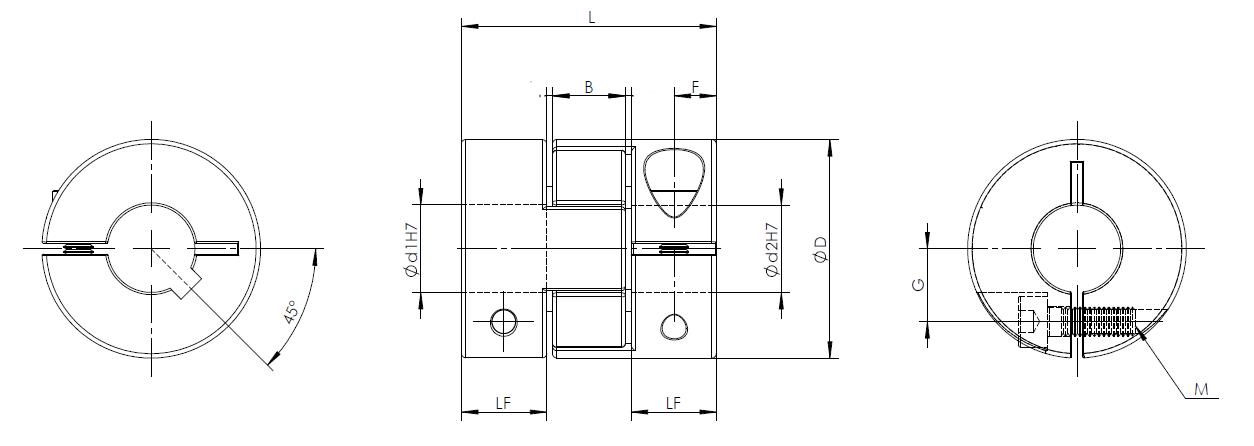

Outer diameter Φ14-Φ30

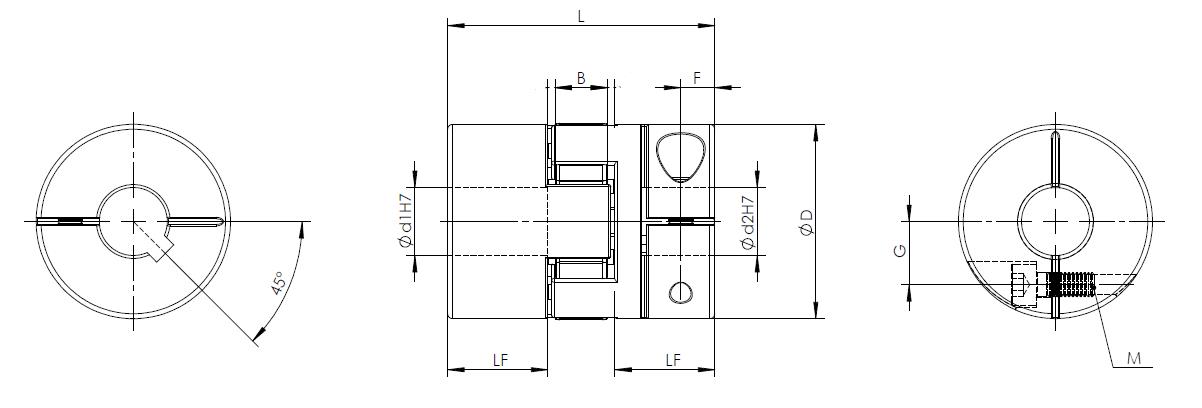

Outer diameter Φ35-Φ40

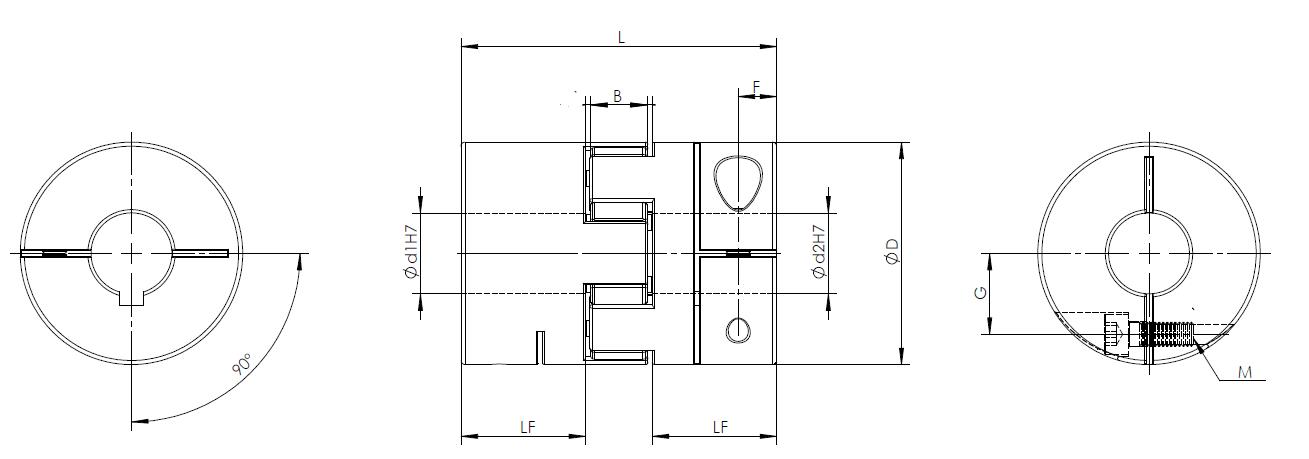

Outer diameter Φ55-Φ120

| Parts |  Material Material |  Surface Treatment Surface Treatment |  Accessory Accessory |

| Hub | Aluminum Alloy | Clear Anodized | Clamp Screw |

| Spacer | Polyurethane | - |

~

~ to select the part no.

to select the part no.Part No.( Type· Type· DL) DL) | - |  d1 d1 | - |  d2 d2 |

| E-LMPJC20L25 E-LMPJC20L30 E-LMPJC30L35 | - - - | 5 7 7 | - - - | 6 8 9 |

| Parrt Number |  d1、 d1、 d2 Shaft Hole dia (d1≤d2) d2 Shaft Hole dia (d1≤d2) | LF | B | F | |||||||||||||||||||||||||||||||||

Type Type |  D D | L | |||||||||||||||||||||||||||||||||||

| E-LMPJC | 14 | L22 | 3 | 4 | 5 | 6 | 6.35 | 7.5 | 6.2 | 3.8 | |||||||||||||||||||||||||||

| 20 | L25 | 3 | 4 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 7.8 | 8 | 3.9 | |||||||||||||||||||||||

| 20 | L30 | 3 | 4 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 10.3 | 8 | 5.8 | |||||||||||||||||||||||

| 25 | L30 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 8.85 | 10.3 | 4.4 | ||||||||||||||||||||

| 25 | L34 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 10.85 | 10.3 | 5.4 | ||||||||||||||||||||

| 30 | L35 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 11.7 | 10 | 5.8 | ||||||||||||||||||

| 30 | L40 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 14.2 | 10 | 7.1 | ||||||||||||||||||

| 35 | L50 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 19.35 | 9.3 | 9.6 | ||||||||||||||||||

| 40 | L40 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 13.1 | 10.8 | 6.5 | ||||||||||||||||||

| 40 | L50 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 18.1 | 10.8 | 9 | |||||||||||||||||

| 40 | L55 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 20.6 | 10.8 | 7 | |||||||||||||||||

| 40 | L66 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 26.1 | 10.8 | 7.5 | |||||||||||||||||

| 55 | L78 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 30.8 | 13.9 | 9.5 | ||||||||||||||||||

| 65 | L90 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 36 | 15 | 12 | ||||||||||||||||||

| 80 | L114 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 45.75 | 18.5 | 15 | ||||||||||||||||||||

| 95 | L126 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 50 | 55 | 51.3 | 20.4 | 15.5 | |||||||||||||||||||

| 105 | L140 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 50 | 55 | 60 | 57.3 | 20.4 | 17.5 | ||||||||||||||||||

| 120 | L160 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 65.7 | 23.6 | 20 | |||||||||||||||||

■Characteristic Values

| Part No. | Rated Torque (N·m) | Angular Misalignment ( ° ) | Lateral Misalignment (mm) | Static Torsional Spring Constant (N·m/rad) | Max. Rotational Speed (r/min) | Moment of Inertia (kg·m2) | Allowable Axial Misalignment (mm) | Clamp Screw | Mass g | |||

| Type | D | L | M | Tightening Torque (N.m) | ||||||||

| E-LMPJC | ||||||||||||

| 20 | L25 | 2.8 | 1 | 0.02 | 55 | 17000 | 1.0x10-6 | ±0.6 | M3 | 1.5 | 15 | |

| 20 | L30 | 1 | 0.02 | 55 | 17000 | 1.1x10-6 | ±0.6 | M4 | 3.5 | 19 | ||

| 25 | L30 | 6 | 1 | 0.02 | 65 | 16000 | 5.2x10-6 | ±0.6 | M4 | 3.5 | 33 | |

| 25 | L34 | 1 | 0.02 | 65 | 16000 | 5.2x10-6 | ±0.6 | M4 | 3.5 | 42 | ||

| 30 | L35 | 6.5 | 1 | 0.02 | 72 | 12000 | 6.2x10-6 | ±0.6 | M4 | 3.5 | 50 | |

| 30 | L40 | 1 | 0.02 | 72 | 12000 | 6.2x10-6 | ±0.6 | M4 | 8 | 60 | ||

| 35 | L50 | 15 | 1 | 0.02 | 200 | 10000 | 8.1x10-6 | ±0.6 | M5 | 8 | 45 | |

| 40 | L40 | 32 | 1 | 0.02 | 450 | 10000 | 3.8x10-5 | ±0.8 | 115 | |||

| 40 | L50 | 1 | 0.02 | 450 | 10000 | 3.8x10-5 | ±0.8 | 115 | ||||

| 40 | L55 | 1 | 0.02 | 500 | 10000 | 3.8x10-5 | ±0.8 | 127 | ||||

| 40 | L66 | 1 | 0.02 | 550 | 10000 | 3.9x10-5 | ±0.8 | 154 | ||||

| 55 | L78 | 46 | 1 | 0.02 | 1500 | 8000 | 1.6x10-3 | ±0.8 | M6 | 13 | 341 | |

| 65 | L90 | 109 | 1 | 0.02 | 2800 | 6000 | 3.8x10-3 | ±0.8 | M8 | 28 | 583 | |

| 80 | L114 | 135 | 1 | 0.02 | 3500 | 4600 | 1.8x10-3 | ±1.0 | M8 | 28 | 1000 | |

| 95 | L126 | 250 | 1 | 0.02 | 5000 | 3800 | 1.8x10-3 | ±1.0 | M10 | 40 | 1500 | |

| 105 | L140 | 420 | 1 | 0.02 | 5400 | 3400 | 3.1x10-3 | ±1.0 | M12 | 75 | 2000 | |

| 120 | L160 | 520 | 1 | 0.02 | 6500 | 3000 | 4.3x10-3 | ±1.0 | M12 | 75 | 2500 | |

The Flexible Shaft Couplings allowable torque varies with temperature.

The Flexible Shaft Couplings allowable torque varies with temperature. Press the adjustment ring into the body to assemble.

Press the adjustment ring into the body to assemble. Press Spacer to the body when install.

Press Spacer to the body when install.

| Shaft Bore Dia. d1·d2 | b(Keyway Width) | t Keyway Depth | Keyway Nominal Dim. b X h | |

| LK | RK | |||

| 8~10 | 3 | 3 | 1.4 | 3x3 |

| 11~12 | 4 | 4 | 1.8 | 4x4 |

| 13~17 | 5 | 5 | 2.3 | 5x5 |

| 18~22 | 6 | 6 | 2.8 | 6x6 |

| 23~30 | 8 | 8 | 3.3 | 8x7 |

| 31~38 | 10 | 10 | 3.3 | 10x8 |

| 39~44 | 12 | 12 | 3.3 | 12x8 |

| 45~50 | 14 | 14 | 3.8 | 14x9 |

| 51~58 | 16 | 16 | 4.3 | 16x10 |

| 59~65 | 18 | 18 | 4.4 | 18x11 |

| 66~75 | 20 | 20 | 4.9 | 20x12 |

| 76~85 | 22 | 22 | 5.4 | 22x14 |

| 86~95 | 25 | 25 | 5.4 | 25x14 |

It has a simple structure, no lubrication required / easy to repair and inspect / maintenance-free. It can operated continuously for a long time.

Polyurethane elastic parts are wear-resistant and oil-resistant, have large load capacity, long service life, and are Flexible Shaft Couplings is safe and reliable.

This product is suitable for medium and high-speed applications.

1. The Flexible Shaft Couplings allows axis deviation, and transmits rotation angle and torque, but when the axis deviation exceeds the allowable value, vibration will occur or the service life will be drastically reduced. Be sure to make calibration andadjustment.

2. Axis deviation includes lateral misalignment (parallel error of two axes), angular misalignment (angular error of two axes) and axial amplitude (axial movement of shaft).

Please calibrate and adjust the shaft to ensure that the axis deviation is below the allowable value recorded in the dimension and performance table of each product.

3. The allowable value of axis deviation recorded in the dimension and performance table refers to the situation when either lateral misalignment, angular misalignment or axial amplitude occurs alone. When more than two axis deviationsoccur at the same time, the corresponding allowable values are halved respectively.

4. Axis deviation not only occurs when assembling to the device, but also is caused by vibration, thermal expansion and bearing wear in operation. Therefore, it is recommended to set the axis deviation below 1/3 of the allowable value.

STEP1 Insert the coupling

Confirm that the clamping bolt has been unscrewed, and then remove the dust, foreign matter and oil from the shaft and Flexible Shaft Couplings bore.

Then, when inserting the coupling into the shaft, please be careful not to put the disc under excessive stress such as compression or tension.

STEP2 Use fixture to adjust

Please use fixture to adjust and fix the concentricity of the left and right hubs of the Flexible Shaft Couplings with high accuracy.

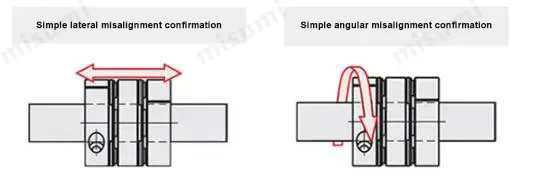

STEP3 Simple lateral misalignment and angular misalignment confirmation

Under the condition of unscrewed bolts, make the Flexible Shaft Couplings slide axially and confirm its smooth movement.

Then, rotate the coupling to make sure it moves smoothly.

Lateral misalignment is not allowed for single disc type coupling, so carry out positioning securely.

Please adjust the shaft insertion amount according to the dimension ℓ in the product catalog, and use a torque wrench to tighten with the specified torque.

* If the specified torque cannot be reached once, please cross fasten the left and right clamps twice or three times.

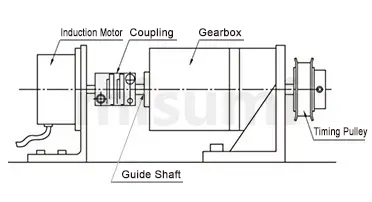

Use example 1: motor × gear box

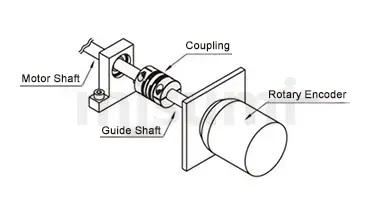

Use example 3: motor × encoder

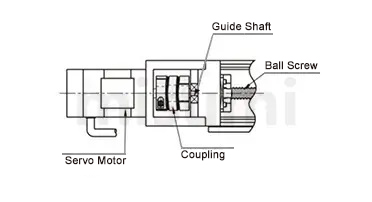

Use example 2: motor × ball screw

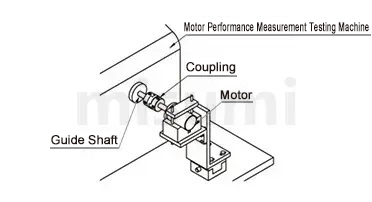

Use example 4: motor × measuring tester