Adjusting Stopper Screws, Fine Thread, Hex Socket

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part09 CLICK here

Product Description

Stopper Screws are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Thead Type : Fine Thread

● Thead Size (Minimum/Maximum) : M3 and M20

● Screw Length L (Minimum/Maximum) (mm.) : 10 to 119 mm. and 1mm Increments

● Material : S45C and SUS304

● Surface Treatment : Trivalent Chromate Treatment for S45C

[Application]

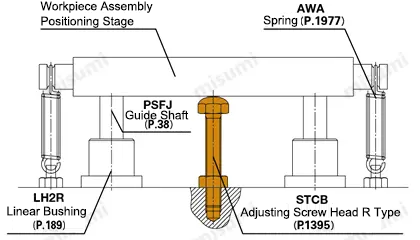

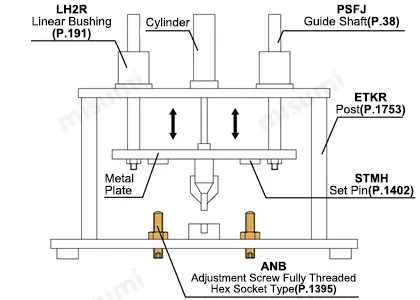

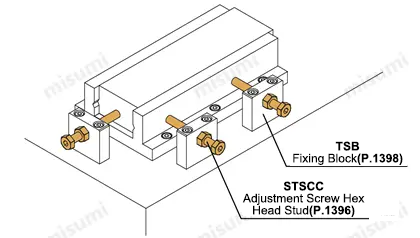

Stopper Screws are commonly used in various applications in factory automation systems

・Available with twomaterials : steel S45C and stainless steel SUS304.

| Adjusting Screw | Type |  Material Material |  Surface Treatment Surface Treatment |  Hardness Hardness |

| Fine Thread | E-ANB | S45C | Trivalent Chromate Treatment | 35~42HRC |

| E-ANBS | SUS304 | - | - |

* The hardness is high due to overall quenching. Do not use them in special applications requiring frequent collisions.

■ Dimension Specification Table

| Part Number |  L L | |||||||||||||||

Type Type |  M M | |||||||||||||||

| (Fine Thread) E-ANB E-ANBS | 3 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | ||||||||

| 4 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | ||||||

| 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | ||||||

| 6 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | |||||||

| 8 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | ||||||||

| 10 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 | |||||

| 12 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 | ||||||

| 16 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 | 120* | |||||||

| 20 | 60 | 70 | 80 | 90 | 100 | 120* | ||||||||||

Product customization is available for dimensions not listed in the table of specifications.Only S45C products are available for dimension L with *.

Product customization is available for dimensions not listed in the table of specifications.Only S45C products are available for dimension L with *.| M | M×Pitch | B1 | ℓ | SR | B | (C) | T | ||

| Fine Thread | Coarse Thread | Fine Thread | Coarse Thread | ||||||

| 3 | 3×0.35 | 3×0.5 | 1.5 | 1.5 | 3 | 5.5 | 6.4 | 2.4 | 2.4 |

| 4 | 4×0.5 | 4×0.7 | 2 | 2.2 | 4 | 7 | 8.1 | 4 | 3.2 |

| 5 | 5×0.5 | 5×0.8 | 2.5 | 2.8 | 5 | 8 | 9.2 | 4 | 4 |

| 6 | 6×0.75 | 6×1.0 | 3 | 3 | 6 | 10 | 11.5 | 4 | 5 |

| 8 | 8×0.75 | 8×1.25 | 4 | 4 | 8 | 13 | 15 | 5 | 6.5 |

| 10 | 10×1.0 | 10×1.5 | 5 | 5 | 10 | 17 | 19.6 | 6 | 8 |

| 12 | 12×1.0 | 12×1.75 | 6 | 6 | 12 | 19 | 21.9 | 6 | 10 |

| 16 | 16×1.5 | 16×2.0 | 8 | 7 | 16 | 24 | 27.7 | 8 | 13 |

| 20 | 20×1.5 | 20×2.5 | 10 | 8 | 20 | 30 | 34.6 | 10 | 16 |

Feature 2 :The overall heat treatment (HRC35~42) has reduced abrasion caused by contact with workpiece.

Feature 3 :Unlike a flat end bolt, the front end round head makes point contact with the workpiece, thus absorbing the inclination of the tapped hole.

Feature 4 :Adjustment Screws coarse or fine thread pitch is available. Choose the fine thread type when slight adjustment is required.

Feature 5 :A nut for fixing the Adjustment Screws is included. Therefore, it can be fixed after purchasing the adjusting screw components.

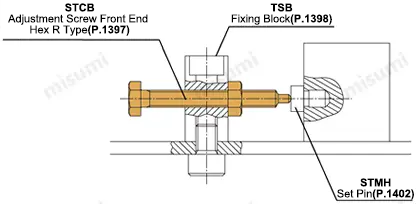

| Product Drawings | Detailed Description about Adjustment Screws usage |

| Due to the Adjustment Screws use of a front end round head shape, it can absorb the eccentricity caused by the inclination of thread processing. Therefore, only one point can be used as a support for positioning. |

| Adjustment Screws has overall heat treatment, there is little wear even after repeated contact caused by collision during positioning. |

| Using Adjustment Screws two adjustment bolts simultaneously on one side of the workpiece can easily achieve lateral positioning. |

| Adjusting screw front end is quenched. If it is necessary to avoid damaging the workpiece during positioning, it is recommended to use it in conjunction with theset pin. |

The economy series products are of high hardness due to overall quenching. Do not use them in applications involving frequent collisions.

| Smart Phones | Electronic & Electrical | Lithium battery | ||

|  |  | ||

| Automotive | Robotics | Medical | ||

|  |  |