Linear Bushing Housing Units With Dowel Holes-Tall Blocks, Single

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part02 CLICK here

Product Description

Linear Bushing Housing Units are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Inner Diameter Minimum/Maximum (mm.) : 5 and 30

● Overall Length Minimum/Maximum (mm.) : 25 and 74

● Dowel Hole : Can selected between Provided / Not Provided

● Operating Temperature (℃) : -20 to 80

● Material : Housing - Aluminum Alloy

● Surface Treatment: Anodized

[Application]

Linear Bushing Housing Units are commonly used in various applications in factory automation systems

Product Overview of Linear Bushings

Linear Bushings Resin retainers are available in black and yellow, with the same performance. Please feel free to use.

Product Features of Linear Bushings

Feature 2: Appropriate specifications can be selected according to the conditions of use.

Feature 3: Linear Bushings Reduced number of parts and machining time.

Dimensional Drawing of Linear Bushings

| Housing of Linear Bushings | Ambient Operating Temp | |

Materia of Linear Bushingsl Materia of Linear Bushingsl |  Surface Treatment Surface Treatment | |

| Aluminum Alloy | Anodized | -20~80℃ |

The interior of the dowel hole is not anodized.

The interior of the dowel hole is not anodized.

Specification Table of Linear Bushings

| Part Number of Linear Bushings |  With or Without Dowel Hole | D | (S) | L | L1 | L2 | h | W | H | R | M1 (Effective Length) | M2 (Effective Length) | C | C1 | d1×t | ||

Type of Linear Bushings Type of Linear Bushings |  dr dr | Tolerance | |||||||||||||||

| E-LBHS | 5 | +0.003 -0.012 | Not Specified (Without Dowel Hole) | 10 | 4 | 25 | 16 | 7 | 13 | 15 | 20 | 5 | M4 (8) | M4 (10) | - | (1) | 6×5 (For M3 Bolts) |

| 6 | 12 | 3 | 27 | 18 | 9 | 14 | 16 | 22 | M4 (11) | 4 | |||||||

| 8 | Not Specified (Without Dowel Hole) P (With Dowel Hole) | 15 | 32 | 20 | 10 | 16 | 20 | 26 | M5 (8.5) | M4 (15) | 5 | ||||||

| 10 | 19 | 4 | 39 | 27 | 15 | 19 | 26 | 32 | 6 | M6 (9.5) | M5 (20) | 6 | 8×6 (For M4 Bolts) | ||||

| 12 | 21 | 40 | 20 | 28 | 34 | M5 (22) | |||||||||||

| 13 | 23 | 42 | 28 | 16 | 25 | 30 | 43 | 7 | M6 (13) | M6 (23) | - | 9×7 (For M5 Bolts) | |||||

| 16 | 28 | 3.8 | 47 | 32 | 18 | 27 | 36 | 49 | M6 (29) | 8 | |||||||

| 20 | +0.003 -0.013 | 32 | 52 | 36 | 31 | 42 | 54 | 8 | M8 (15) | M8 (34) | - | 11×8 (For M6 Bolts) | |||||

| 25 | 40 | 3.2 | 69 | 42 | 22 | 37 | 52 | 65 | 9 | M10 (17) | M10 (42) | - | 14×10 (For M8 Bolts) | ||||

| 30 | 45 | 74 | 44 | 40 | 58 | 71 | M10 (17.5) | M10 (48) | - | ||||||||

| Part Number |  With or Without Dowel Hole | D | (S) | L | L1 | L2 | h | W | H | R | M1 (Effective Length) | M2 (Effective Length) | C | C1 | d1×t | ||

Type Type |  dr dr | Tolerance | |||||||||||||||

| E-LBHS | 5 | +0.003 -0.012 | Not Specified (Without Dowel Hole) | 10 | 4 | 25 | 16 | 7 | 13 | 15 | 20 | 5 | M4 (8) | M4 (10) | - | (1) | 6×5 (For M3 Bolts) |

| 6 | 12 | 3 | 27 | 18 | 9 | 14 | 16 | 22 | M4 (11) | 4 | |||||||

| 8 | Not Specified (Without Dowel Hole) P (With Dowel Hole) | 15 | 32 | 20 | 10 | 16 | 20 | 26 | M5 (8.5) | M4 (15) | 5 | ||||||

| 10 | 19 | 4 | 39 | 27 | 15 | 19 | 26 | 32 | 6 | M6 (9.5) | M5 (20) | 6 | 8×6 (For M4 Bolts) | ||||

| 12 | 21 | 40 | 20 | 28 | 34 | M5 (22) | |||||||||||

| 13 | 23 | 42 | 28 | 16 | 25 | 30 | 43 | 7 | M6 (13) | M6 (23) | - | 9×7 (For M5 Bolts) | |||||

| 16 | 28 | 3.8 | 47 | 32 | 18 | 27 | 36 | 49 | M6 (29) | 8 | |||||||

| 20 | +0.003 -0.013 | 32 | 52 | 36 | 31 | 42 | 54 | 8 | M8 (15) | M8 (34) | - | 11×8 (For M6 Bolts) | |||||

| 25 | 40 | 3.2 | 69 | 42 | 22 | 37 | 52 | 65 | 9 | M10 (17) | M10 (42) | - | 14×10 (For M8 Bolts) | ||||

| 30 | 45 | 74 | 44 | 40 | 58 | 71 | M10 (17.5) | M10 (48) | - | ||||||||

| dr | Dowel Hole Dimensions | Basic Load Rating | Mass (g) | |||||

| P | C | ℓ2 | E | F | C (Dynamic) N | Co (Static) N | ||

| 5 | - | - | - | - | - | 167 | 206 | 18 |

| 6 | 206 | 265 | 22 | |||||

| 8 | 3 | 4 | 4 | 22 | 12 | 265 | 380 | 40 |

| 10 | 4 | 5 | 5 | 29 | 16 | 372 | 549 | 80 |

| 12 | 18 | 412 | 598 | 90 | ||||

| 13 | 30 | 20 | 510 | 608 | 132 | |||

| 16 | 32 | 775 | 1180 | 204 | ||||

| 20 | 5 | 6 | 6 | 36 | 882 | 1370 | 272 | |

| 25 | 42 | 26 | 980 | 1570 | 574 | |||

| 30 | 44 | 30 | 1570 | 2740 | 710 | |||

| Housing | Ambient Operating Temp | |

Material Material |  Surface Treatment Surface Treatment | |

| Aluminum Alloy | Anodized | -20~80℃ |

The interior of the dowel hole is not anodized.

The interior of the dowel hole is not anodized.| Product Drawings | Instructions for use |

| When the linear bearing is under heavy load (unbalanced load), one piece of single liner type is not applicable. It is recommended to use one piece of double liner type or multiple pieces of single liner type. |

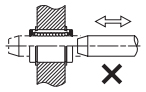

| Linear bearing is not suitable for rotating motion in structure. If you rotate forcibly, it may cause damage to the product. Please pay attention during use. |

| Linear bearing is not suitable for repeated plugging and unplugging. |

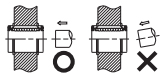

| When inserting the guide shaft into the linear bearing, please align the center and insert it slowly, otherwise the steel ball will fall off or the retainer will be deformed. |

Precautions

■ Dust prevention measures:

If dust or foreign matter enters the inside of the linear bushing, it may damage the circulation of steel balls, resulting in unexpected failures. When used in harsh environment, please install dust cover and protection cover, etc.

■ MISUMI linear bushing is recommended to be combined with guide shaft with quenching g6 tolerance.

■ MISUMI linear bushing is recommended to be installed on the holder with H7 tolerance. The linear bushing is in clearance fit with the housing.

Usage Method.

Usage Method.| Electronic & Electrical | Automotive | Lithium battery | ||

|  |  | ||

| LCD | Smart Phones | Semiconductor | ||

|  |  |