Motorized Rotary Stages Ball Screw Type, Position Repeatability ±0.01°

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

Motorized Rotary Stages are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Table Outer Diameter Minimum/Maximum (mm.) : 40 and 120

● Ball screw transmission is adopted to achieve small-angle rotary positioning.

● Load Capacity (N) : 39.2 to 117.6

● Material and Surface Treatment : Aluminum Alloy Black Anodized

[Application]

Motorized Rotary Stages are commonly used in various applications in factory automation systems

Material: Aluminum Alloy

Material: Aluminum Alloy Surface Treatment: Black Anodized

Surface Treatment: Black AnodizedSpecifications Overview of Rotary

Body Material of Rotary Body Material of Rotary |  Surface Treatment of Rotary Surface Treatment of Rotary | Travel Distance (°) | Load Capacity (N) | Accuracy Specification | ||

| One-Way Positioning Accuracy | Repetitive Positioning Accuracy | Parallelism | ||||

| Aluminum Alloy | Black Anodized | ±12°~±12.5° | 39.2~117.6 | 0.08° | ±0.01° | 50μm |

| Part Number |  Driver Driver |  Cable Cable | Mechanical Specifications | Accuracy Specifications | ||||||

Type Type |  No. No. | Slide Table Surface (mm) | Movement (°) | Load Capacity (N) | Weight (kg) | Maximum Speed (°/sec) | Repeat Positioning Accuracy | Parallelism (µm) | ||

| E-RMBG | 40 | A (Single-axis pulse driver) N (No driver) | ⌀40 | ±12.3 | 39.2 | 0.5 | 28 | Within ±0.01° | 50 or Less | |

| 60 | 2 (2 m cable) | ⌀59 | ±12 | 58.8 | 0.7 | 24 | ||||

| 80 | ⌀80 | ±12 | 78.4 | 1.4 | 16 | |||||

| 100 | 4 (4 m cable) | ⌀100 | ±12.5 | 98 | 1.8 | 12 | ||||

| 120 | ⌀120 | ±12 | 117.6 | 2.3 | 12 | |||||

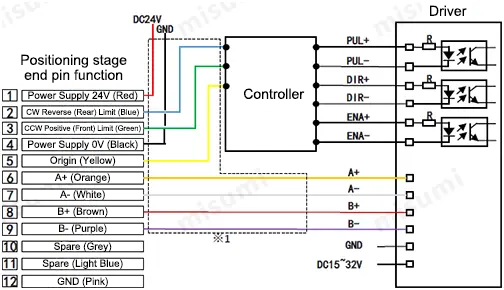

Driver: The driver model used in this series: E-DR42B (Chinese only).

Driver: The driver model used in this series: E-DR42B (Chinese only). Bus driver brand and model: Leadshine DM3C-EC522 (Chinese ony).

Bus driver brand and model: Leadshine DM3C-EC522 (Chinese ony). Cable: Cable models used in this series: HRS12-2M (2-meter cable) / HRS12-4M (4-meter cable).

Cable: Cable models used in this series: HRS12-2M (2-meter cable) / HRS12-4M (4-meter cable). For the servo motor mounting bracket, recommended motor brands are Yaskawa, Inovance, Mitsubishi, Leadshine, etc. Recommended power ratings are 50W and 100W. Please carefully check the motor mounting dimensions.

For the servo motor mounting bracket, recommended motor brands are Yaskawa, Inovance, Mitsubishi, Leadshine, etc. Recommended power ratings are 50W and 100W. Please carefully check the motor mounting dimensions.■ General Specifications

| No. | 40 | 60 | 80 | 100 | 120 | |

| Feed Screw | Ball Screw ⌀6, Lead 1 mm | |||||

| Bearing | Angular Contact Ball Bearing | |||||

| Motor | Shape | 2-Phase Standard Stepper Motor 1.3 A/Phase | 2-Phase High Torque Stepper Motor 1.3 A/Phase | |||

| Step Angle | 1.8° | |||||

| Resolution (Pulse) Full | ≒0.0136° | ≒0.0119° | ≒0.0080° | ≒0.0064° | ≒0.0052° | |

| Driver | Power Voltage | DC12 to 50 V | ||||

| Output Current | 0.1 to 2.2 A | |||||

| Pulse Signal Voltage | 5 to 24 V | |||||

| Number of Subdivisions | 200 to 51200 | |||||

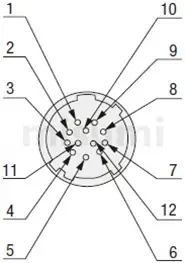

| Connector | Part Number | HR10A-10R-12P (Hirose) | ||||

| Receiving side part number | HR10A-10P-12S (Hirose) | |||||

| Sensor Substrate | Limit Sensor | Provided | ||||

| Origin Sensor | Provided | |||||

| Power Voltage | 24 V DC±10% | |||||

| Sensor Type | Miniature Photo Sensor RPI-0125 (ROHM) | |||||

| Control Output | NPN Open Collector Output | |||||

| Output Logic | During detection (shading): Output transistor OFF (non-conducting) | |||||

■ Wiring Diagram

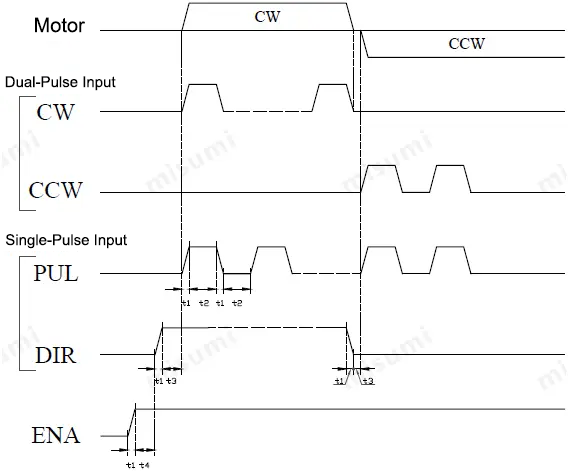

■ Timing Diagram

t1<0.1us t2 ≥ 0.9us t3 ≥ 10us

t4: ENA (Enable signal) t4 should be set high at least 10µs before DIR. In general, it is recommended to leave ENA+ and ENA- unconnected.

Product Features

Feature 2: Optimized structure and lower prices through local production.

Feature 3: Quick assembly and disassembly achieved by adding positioning holes to the slide table surface.

Feature 4: The standard driver supports both dual-pulse and pulse + direction control, meeting the needs of various operating conditions.

Usage Method

Precautions

Operating environment: 10 to 50°C, 20 to 70%RH (non-condensing)

Recommended environment: 22±5°C, 20 to 70%RH (non-condensing)

Please avoid using the slide table in the following environments

(1) Dusty environments (especially metal powder)

(2) Environments with direct sunlight or heat radiation

(3) Near fire sources

(4) Environments with corrosive or flammable gases

(5) Environments with splashing water or oil

(6) Environments with strong vibration or impact

(7) Environments with organic solvents or high salt content

■About Slide Table Maintenance

There is no unified regular maintenance standard due to differences in grease types and usage environments. Depending on the drive conditions and the type of guide rail, please be sure to check the grease at least once a month.

Application Industries

Related Products

| Economy Electric Slide Table X-Axis | Economy Electric Slide Table XY Axis | Economy Electric Slide Table Z-Axis |

|  |  |

| Representative Model: C-XMBS420-L-A-2 | Representative Model: C-XYMBS420-L-A-2 | Representative Model: C-ZMBS420-L-A-2 |

Compatible drivers support dual-pulse and pulse + direction control. For installation dimensions and user manual, please refer to: E-DR42B.