Disc Springs

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part11 CLICK here

Product Description

Disc Springs

Disc Springs also known as belleville spring are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Outer Diameter Minimum/Maximum (mm.) : 6 and 125

● Inner Diameter Minimum/Maximum (mm.) : 3.2 and 64

● Free State Height Minimum/Maximum (mm.) : 0.45 and 10.6. (depend on product code)

● Material : 50CrVA / SUS304

● Surface treatment : Phosphating

[Application]

Disc springs are utilized in bolted joints to maintain the desired preload force.

Disc springs are springs formed by making a hole in the center of a disk to create a conical disc shape. Unlike traditional springs, they have unique functions.

Can withstand heavy loads with small deformation, has a short stroke, requires little space, is easy to use in combination, convenient for maintenance and replacement, highly economical and safe, and has a long service life.

At the same time, it is also considered a spring with a high level of design difficulty. When used in stacks, even slight dimensional differences can have a significant impact on the load, and may also cause a reversal in the relationship between displacement and load.

.jpg)

*CAD is not ready with Some Part Number.

· Material Table

Material: 50CrVA

Material: 50CrVA Surface Treatment: Phosphating

Surface Treatment: Phosphating

| Part Number | Tolerance (D) mm | Inner Diameter (d) mm | Tolerance (d) mm | Plate Thickness (t) mm | Free Height (H0) mm | Tolerance (H0) mm | Maximum Deformation (h) mm | Load (at 75% displacement) N | ||

Type Type |  Outer Diameter (D) Outer Diameter (D)mm |  Load LoadShape | ||||||||

| E-SRBN (50CrVA) E-SSRBN (SUS304) | 6 | B | 0 —0.12 | 3.2 | +0.12 0 | 0.3 | 0.45 | +0.1 —0.05 | 0.15 | 119 (110) |

| 8 | A | 0 to 0.15 | 4.2 | +0.15 0 | 0.55 | 0.25 | 119 | |||

| B | 0.4 | 0.6 | 0.2 | 210 | ||||||

| 10 | A | 5.2 | 0.7 | 0.3 | 213 | |||||

| B | 0.5 | 0.75 | 0.25 | 323 | ||||||

| 12.5 | A | 0 —0.18 | 6.2 | 0.85 | 0.35 | 294 | ||||

| B | 0.7 | 1 | 0.3 | 657 | ||||||

| 14 | A | 7.2 | 0.5 | 0.9 | 0.4 | 274 | ||||

| B | 0.8 | 1.1 | 0.3 | 813 | ||||||

| 16 | A | 8.2 | 0.6 | 1.05 | 0.45 | 411 | ||||

| B | 0.9 | 1.25 | 0.35 | 1029 | ||||||

| 18 | A | 9.2 | 0.7 | 1.2 | 0.5 | 568 | ||||

| B | 1 | 1.4 | 0.4 | 1274 | ||||||

| 20 | A | 0 -0.21 | 10.2 | +0.18 0 | 0.8 | 1.35 | 0.55 | 745 | ||

| B | 1.1 | 1.55 | 0.45 | 1520 | ||||||

| 22.5 | A | 11.2 | 0.8 | 1.45 | 0.65 | 710 | ||||

| B | 1.25 | 1.75 | +0.15 -0.08 | 0.5 | 1950 | |||||

| 25 | A | 12.2 | 0.9 | 1.6 | +0.10 -0.05 | 0.7 | 868 | |||

| B | 1.5 | 2.05 | +0.15 -0.08 | 0.55 | 2910 | |||||

| 28 | A | 14.2 | 1 | 1.8 | +0.10 -0.05 | 0.8 | 1110 | |||

| B | 1.5 | 2.15 | +0.15 -0.08 | 0.65 | 2850 | |||||

| 31.5 | A | 0 —0.25 | 16.3 | 1.25 | 2.15 | 0.9 | 1920 | |||

| B | 1.75 | 2.45 | 0.7 | 3900 | ||||||

| 35.5 | A | 18.3 | +0.21 0 | 1.25 | 2.25 | 1 | 1700 | |||

| B | 2 | 2.8 | 0.8 | 5190 | ||||||

| 40 | A | 20.4 | 1.5 | 2.65 | 1.15 | 2620 | ||||

| B | 2.25 | 3.15 | +0.20 -0.10 | 0.9 | 6540 | |||||

| 45 | A | 22.4 | 1.75 | 3.05 | +0.15 -0.08 | 1.3 | 3660 | |||

| B | 2.5 | 3.5 | +0.20 -0.10 | 1 | 7720 | |||||

| 50 | A | 25.4 | 2 | 3.4 | +0.15 -0.08 | 1.4 | 4756 | |||

| B | 3 | 4.1 | +0.20 -0.10 | 1.1 | 11964 | |||||

| 56 | A | 0 -0.30 | 28.5 | +0.21 0 | 2 | 3.6 | +0.15 -0.08 | 1.6 | 4438(4093) | |

| B | 3 | 4.3 | +0.20 -0.10 | 1.3 | 11388(10504) | |||||

| 63 | A | 31 | +0.25 0 | 2.5 | 4.25 | 1.75 | 7189(6631) | |||

| B | 3.5 | 4.9 | +0.30 -0.15 | 1.4 | 15025(13858) | |||||

| 71 | A | 36 | 2.5 | 4.5 | +0.20 -0.10 | 2 | 6725(6203) | |||

| B | 4 | 5.6 | +0.30 -0.15 | 1.6 | 20535(18940) | |||||

| 80 | A | 41 | 3 | 5.3 | +0.20 -0.10 | 2.3 | 10518(9701) | |||

| B | 5 | 6.7 | +0.30 -0.15 | 1.7 | 33559(30953) | |||||

| 90 | A | 0 -0.35 | 46 | 3.5 | 6 | 2.5 | 14161(13061) | |||

| B | 5 | 7 | 2 | 31354(28919) | ||||||

| 100 | A | 51 | +0.30 0 | 3.5 | 6.3 | 2.8 | 13070 | |||

| B | 6 | 8.2 | 2.2 | 48022 | ||||||

| 125 | A | 0 —0.40 | 64 | 5 | 8.5 | 3.5 | 29908 | |||

| B | 8 (7.5) | 10.6 | ±0.30 | 2.6 | 85926 | |||||

The plate thickness (t) in the specification table is the nominal value; the value in parentheses is the actual plate thickness.

The plate thickness (t) in the specification table is the nominal value; the value in parentheses is the actual plate thickness. Please refer to the value in parentheses for the load of E-SSRBN. kgf=N × 0.101972

Please refer to the value in parentheses for the load of E-SSRBN. kgf=N × 0.1019721. High stiffness, strong cushioning and vibration absorption capability, able to withstand large loads with small deformation, suitable for applications with limited axial space.

2. This type of spring has variable stiffness characteristics.

3. By using the same disc springs in different combinations, the spring characteristics can be varied over a wide range.

Can be arranged in parallel overlap, vertical combination, or a combination of parallel and vertical arrangements.

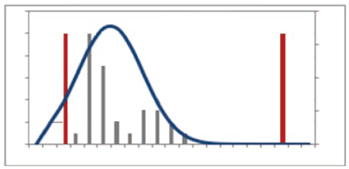

■ Differences between MISUMI Economy Series and Market Standard Products

| Products circulating on the market * | MISUMI Economy series |

| 24H Salt Spray Test Results | 48H Salt Spray Test Results |

| Surface treatment: black oxide coating | Surface treatment: phosphating |

|  |

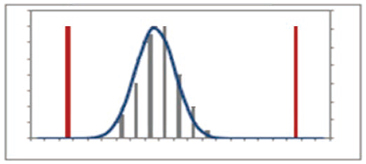

■ Dimensional Consistency Test

| Products circulating on the market * | MISUMI economy series | |

| 30PC Consistency Test (CPK) | 50PC Consistency Test (CPK) | |

Tolerance of Spring Height (H0) CPK=0.48 | Tolerance of Spring Height (H0) CPK=1.48 | Product dimensional consistency is three times that of products circulating on the market |

| Overlapping use may cause unstable performance | Ensure stable performance when used in overlap | |

*Products circulating on the market are similar products randomly purchased by our company from online or offline markets

*The test data are obtained through testing by our company, which are for reference only

*When using disc springs in combination, a guide rod or guide sleeve is required for the inner or outer diameter. The shape of the spring changes as it is compressed, so it is important to consider the clearance with the guide component.

| Inside/Outside diameter (mm) | Recommended Clearance (mm) |

| 15 or Less | 0.2 |

| 20 or Less | 0.3 |

| 26 or Less | 0.4 |

| 45 or Less | 0.6 |

| 75 or less | 0.8 |

| 140 or Less | 1.0 |

| 250 or Less | 1.6 |

Hardness

Hardness