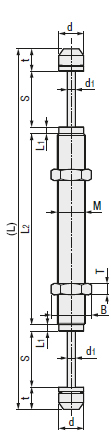

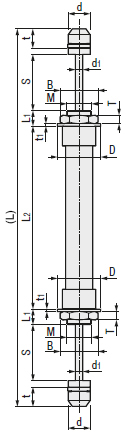

Shock Absorbers, Two-Way Type

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

Shock Absorbers are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Mounting Screw Normial (M) : M20 X 1.5

● Stroke(mm) : 35, 45 and 50

● Service life : 800,000 cycles

● Operating Temperature (℃) : -5 to 70

● Material

Body - STKM11A

Cover - Urethane

[Application]

Shock Absorbers are commonly used in various applications in factory automation systems

Economy Two-Way Shock Absorber

- Features a unique two-way structure with multiple stroke options.

- Crafted from high-quality STKM11A for the body and durable urethane for the cover. Ensures longevity and resilience, providing reliable performance in demanding environments.

- Engineered to withstand a high number of cycles.

- Functions effectively between -5°C to 70°C. Suitable for a variety of industrial settings, maintaining performance despite temperature variations.

- Accommodates high maximum collision velocities.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

The economy series two-way type shock Shock Absorbers has a unique double stroke structure, effectively reducing the installation space and trial cost.

Its automatic compensation structure can produce a consistently soft Shock Absorbers effect.

The advantages of using shock Shock Absorbers:

1. Improve production efficiency: equipment can be operated at high frequency and high speed to improve production efficiency because the shock absorber can stop the impact object smoothly.

2. Extend mechanical life: the buffer can absorb the energy generated by the impact, greatly reduce the impact and vibration caused by the object to the machine, and avoid damage due to impact vibration.

3. Improve Shock Absorbers product quality: the buffer eliminates the shock caused by impact objects and the damaging impact, allowing the smooth operation of the machine and equipment, and improving the product quality.

4. Significantly reduce noise, and provide a quiet working environment.

5. Improve the safety of mechanical running.

| Impact Speed Type | Maximum Collision Velocity | Operating Environment Temperature | Reference number of replacements |

| Two-Way Type | ~4.0m/s | -5 to 70℃ | 800,000 cycles |

■Shock Absorbers Material Table

Shock Absorbers Material Shock Absorbers Material | |

| Body | Cover |

| STKM11A | Urethane |

Surface Treatment Surface Treatment | |

| Threadless Type | Chemical Nickel |

| Fully Threaded, Semi-Threaded Type | Ferroferric Oxide Protective Film |

| Part Number | Mounting Screw Nominal (M) | Stroke (S) | Max. Energy Absorbed (E') | Max. Equivalent Mass (me') (kg) | Max. Collision Velocity (M/S) | Thread Type | Total Length (L) | L1 | L2 | T | t | t1 | D | d | d1 | B (Both Surfaces Width) | ||

Type Type |  No. No. | Per Cycle (J) | Per Minute (J) | |||||||||||||||

| E-MSSTACD | 2035L | M20×1.5 | 35 | 52 | 1030 | 650 | 1 | Semi-Threaded | 234.6 | 49 | 84 | 8 | 15.8 | - | - | 18 | 6 | 26 |

| 2035M | M20×1.5 | 35 | 52 | 1030 | 200 | 2 | 234.6 | 49 | 84 | 8 | 15.8 | - | - | 18 | 6 | 26 | ||

| 2035H | M20×1.5 | 35 | 52 | 1030 | 40 | 3.5 | 234.6 | 49 | 84 | 8 | 15.8 | - | - | 18 | 6 | 26 | ||

| 2045 | M20×1.5 | 45 | 55 | 2290 | 350 | 4 | Fully-Threaded | 275.6 | 2.5 | 149 | 8 | 15.8 | - | - | 18 | 6 | 26 | |

| 2050L | M20×1.5 | 50 | 60 | 2500 | 400 | 4 | 319.6 | 2.5 | 183 | 8 | 15.8 | - | - | 18 | 6 | 26 | ||

| 2050M | M20×1.5 | 50 | 60 | 2500 | 400 | 4 | Threadless | 313.6 | 12.5 | 148 | 8 | 15.8 | 3 | 27 | 18 | 6 | 26 | |

2. Miniaturized design and strong space adaptability.

3. Shock Absorbers energy smoothly and softly.

4. Abundant stock and fast delivery.

5. Long life with 800,000 times being used for reference.

| Coarse Outer Diameter (mm) | M8×1.0 | M10×1.0 | M12×1.0 | M14×1.5 | M20×1.5 | M25×1.5 | M27×1.5 |

| Tightening torque of nut (N.m) | 3.9 | 7.8 | 7.8 | 9.8 | 29.4 | 49 | 58.8 |

2. Shock Absorbers Pay attention to check whether the head circlip is off.

■ Overloaded buffer will cause abnormal increase in the internal pressure of the buffer tube, making the head circlip off, and internal parts may pop up and cause injury.

■ When the buffer with the head circlip is working, please keep your face and other parts away from it.

3. Please pay attention to the splash of the broken buffer head due to impact.

■ Overload use will cause damage to the head, resulting in injury.

■ It is recommended to install an anti-splashing cover.

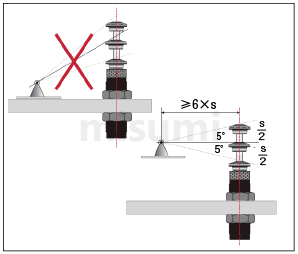

4. Please pay attention to lateral misalignment load and lateral misalignment angle.

■ When the lateral misalignment load exceeds ±2.5 degrees, it will cause piston rod bending, bad reset, and internal lateral misalignment friction, resulting in performance degradation and even product breakage.

Please aim at the center line of the buffer piston rod for impact. (If the lateral misalignment angle is greater than ±2.5 degrees, please use the angular misalignment Shock Absorbers (the range of lateral misalignment:± within 10 degrees)

5. Operating Temperature Range

■ Please use the buffer within the specified temperature range.

▪ Use outside the specified range will reduce the life of the seal packing and the pressure accumulating sponge, and cause the buffer to break.

6. Shock Absorbers Operating Environment Requirements

■ Please do not use it under medium or high pressure in a vacuum environment.

■ Keep the guide shaft clean, and avoid cutting powder, cutting fluid, water, etc. from being attached to the guide shaft, otherwise it will cause seal damage, oil leakage, poor buffer action, and buffer damage.

※ If you need to use it in the cutting fluid environment, please choose Misumi’s cutting fluid resistant buffer series products. See Misumi's official website.

8. Shock Absorbers To prevent the buffer from increasing lateral load, the distance between the installation position of the buffer and the fulcrum should be equal to or greater than 6 times of the buffer stroke.

And when the side load and the buffer center line form an angle of 5°, the Shock Absorbers energy is the maximum.

Example of Shock Absorbers Use 1