Torsion Springs, Arm Angle (90°/135°/180°)

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part11 CLICK here

Product Description

· Economy Torsion Springs Series -Arm angles of 90°/135°/180°.

· The series includes C-UA90R, C-UA90L, C-UA135R, C-UA135L, C-UA180R and C-UA180R.

· Material: Stainless Steel (SUS304-WPB)

· Arm Angle: 90°/135°/180°.

· Type of Arm Angle: Right Winding and Left Winding

· Inner Diameter: 2, 3, 4, 5 and 6

· Number of coil n: 3, 4 and 5.

· Torsion springs are used in various applications such as automotive, aerospace, industrial machinery, and electrical devices.

· Torsion springs are designed to generate torque or rotational force when twisted or subjected to angular deflection.

Economy Torsion Spring

- Material: Stainless steel (SUS304-WPB) for corrosion resistance and durability.

- Design: Multiple arm angle options to suit various applications.

- Customization: Options for right and left-hand winding, as well as arm length and bending alterations.

- Spring with customizable dimensions

- Torque Generation: Produces rotational force when twisted.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Torsion Springs Product Overview

♢ The torsion spring is a type of coil springs. The end of the torsion spring is fixed to other components. When other components rotate around the spring center, the spring will pull them back to the initial position to generate torque or rotation force.

It is used to control the movement of machine parts, alleviate impact or vibration, store energy, measure force, etc. It is widely used in computers, electronics, home appliances, cameras, instruments, doors, motorcycles, harvesters, automobiles and other industries.

The end of the spring can be wound into a hook-shaped or straight torsion arm.

Torsion Springs Product Features

♢ Standard products right-hand wound are in stock and can be shipped next day after the order is placed, while the products left-hand wound can be shipped within 5 days after the order is placed.

♢ Alteration can be made to the length and bending in a short delivery time and small batches (shipping within 5 days for alteration to the length and 6 days for the alteration to the bending).

♢ The strength and service life can be guaranteed by using imported wire materials.

♢ The Torsion Springs is used to control the movement of machine parts, alleviate impact or vibration, store energy, measure force, etc. It is widely used in computers, electronics, home appliances, cameras, instruments, doors, motorcycles, harvesters, automobiles and other industries.

Torsion Springs Dimensional Drawing

Material SUS304-WPB (Imported from Japan)

Material SUS304-WPB (Imported from Japan)Torsion Springs Specifications Overview

| Part Number |  Number of Coils Number of Coilsn |  Wire Diameter Wire Diameterd |  Alteration Type Alteration Type | Arm Length L·R | Spring Constant (Torque) N··mm/deg | Maximum Usage Angle deg (°) | |||||

Type Type |  Inner diameter Inner diameterD | Arm Angle 90° | Arm Angle 135° | Arm Angle 180° | Arm Angle 90° | Arm Angle 135° | Arm Angle 180° | ||||

| Arm angle 90° (right-hand wound) (left-hand wound) Arm angle 135° (right-hand wound) (left-hand wound) Arm angle 180° (right-hand wound) (left-hand wound) (  The spring constant is The spring constant isthe reference value when the arm length is cut into L/2 and R/2.) 1N=0.101972kgf 1deg=1° (Angle) | 2 | 5 | 0.3 | A (single arm length specified) B (single arm bent) C (double arms length specified) D (single arm length specified+single arm bent) E (double arms bent) F (double arm length specified+single arm bent) G (single arm length specified+double arms bent) H (double arms length specified+double arms bent) * Select N/A here on the web page if no alteration is required. | 20 | 0.0289 | 0.0295 | 0.0302 | 61 | 60 | 58 |

| 0.4 | 0.0882 | 0.09 | 0.092 | 46 | 45 | 43 | |||||

| 3 | 3 | 0.3 | 30 | 0.0295 | 0.0304 | 0.0314 | 56 | 54 | 52 | ||

| 0.4 | 0.0912 | 0.094 | 0.097 | 42 | 40 | 39 | |||||

| 4 | 0.4 | 0.0736 | 0.0755 | 0.0774 | 55 | 53 | 51 | ||||

| 0.5 | 0.1756 | 0.1799 | 0.1845 | 44 | 42 | 41 | |||||

| 5 | 0.4 | 0.0617 | 0.063 | 0.0643 | 71 | 68 | 66 | ||||

| 0.5 | 0.1471 | 0.1501 | 0.1533 | 54 | 53 | 51 | |||||

| 4 | 3 | 0.4 | 40 | 0.07 | 0.0722 | 0.0744 | 56 | 54 | 52 | ||

| 0.5 | 0.168 | 0.1732 | 0.1787 | 42 | 41 | 40 | |||||

| 4 | 0.5 | 0.1357 | 0.139 | 0.1425 | 57 | 54 | 52 | ||||

| 0.6 | 0.2763 | 0.2831 | 0.2903 | 48 | 47 | 45 | |||||

| 5 | 0.5 | 0.1138 | 0.1161 | 0.1185 | 69 | 67 | 65 | ||||

| 0.6 | 0.2315 | 0.2363 | 0.2413 | 60 | 59 | 58 | |||||

| 5 | 3 | 0.5 | 50 | 0.1368 | 0.1409 | 0.1454 | 55 | 52 | 51 | ||

| 0.6 | 0.2797 | 0.2883 | 0.2974 | 47 | 44 | 42 | |||||

| 4 | 0.6 | 0.2259 | 0.2314 | 0.2373 | 60 | 58 | 56 | ||||

| 0.8 | 0.6936 | 0.7108 | 0.7289 | 42 | 41 | 40 | |||||

| 5 | 0.6 | 0.1894 | 0.1933 | 0.1974 | 75 | 73 | 71 | ||||

| 0.8 | 0.5811 | 0.5931 | 0.6056 | 54 | 53 | 52 | |||||

| 6 | 3 | 0.6 | 60 | 0.2363 | 0.2436 | 0.2512 | 56 | 52 | 50 | ||

| 0.8 | 0.7299 | 0.7523 | 0.7762 | 38 | 36 | 35 | |||||

| 4 | 0.8 | 0.5891 | 0.6037 | 0.619 | 50 | 48 | 47 | ||||

| 1 | 1.4045 | 1.4394 | 1.476 | 42 | 40 | 39 | |||||

| 5 | 0.8 | 0.4939 | 0.5041 | 0.5147 | 63 | 61 | 60 | ||||

| 1 | 1.1765 | 1.2008 | 1.2262 | 51 | 50 | 49 | |||||

Torsion Springs Alteration

Torsion Springs Precautions

2. In applications without pre-twisting, the spring may be twisted due to vertical vibration caused by the gap. With pre-twisting, the spring works stably.

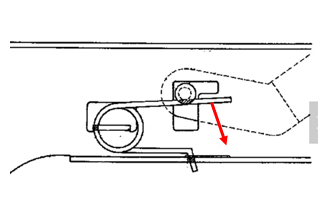

3. In applications where the spring is placed transversely, it may cause abrasion and breakage of the guide pin and spring.

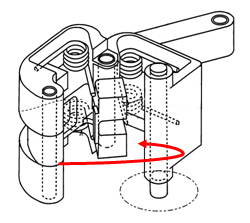

Torsion Springs Example of Use

Material SUS304-WPB (Imported from Japan)

Material SUS304-WPB (Imported from Japan)| Part Number |  Number of Coils Number of Coilsn |  Wire Diameter Wire Diameterd |  Alteration Type Alteration Type | Arm Length L·R | Spring Constant (Torque) N··mm/deg | Maximum Usage Angle deg (°) | |||||

Type Type |  Inner diameter Inner diameterD | Arm Angle 90° | Arm Angle 135° | Arm Angle 180° | Arm Angle 90° | Arm Angle 135° | Arm Angle 180° | ||||

| Arm angle 90° (right-hand wound) (left-hand wound) Arm angle 135° (right-hand wound) (left-hand wound) Arm angle 180° (right-hand wound) (left-hand wound) (  The spring constant is The spring constant isthe reference value when the arm length is cut into L/2 and R/2.) 1N=0.101972kgf 1deg=1° (Angle) | 2 | 5 | 0.3 | A (single arm length specified) B (single arm bent) C (double arms length specified) D (single arm length specified+single arm bent) E (double arms bent) F (double arm length specified+single arm bent) G (single arm length specified+double arms bent) H (double arms length specified+double arms bent) * Select N/A here on the web page if no alteration is required. | 20 | 0.0289 | 0.0295 | 0.0302 | 61 | 60 | 58 |

| 0.4 | 0.0882 | 0.09 | 0.092 | 46 | 45 | 43 | |||||

| 3 | 3 | 0.3 | 30 | 0.0295 | 0.0304 | 0.0314 | 56 | 54 | 52 | ||

| 0.4 | 0.0912 | 0.094 | 0.097 | 42 | 40 | 39 | |||||

| 4 | 0.4 | 0.0736 | 0.0755 | 0.0774 | 55 | 53 | 51 | ||||

| 0.5 | 0.1756 | 0.1799 | 0.1845 | 44 | 42 | 41 | |||||

| 5 | 0.4 | 0.0617 | 0.063 | 0.0643 | 71 | 68 | 66 | ||||

| 0.5 | 0.1471 | 0.1501 | 0.1533 | 54 | 53 | 51 | |||||

| 4 | 3 | 0.4 | 40 | 0.07 | 0.0722 | 0.0744 | 56 | 54 | 52 | ||

| 0.5 | 0.168 | 0.1732 | 0.1787 | 42 | 41 | 40 | |||||

| 4 | 0.5 | 0.1357 | 0.139 | 0.1425 | 57 | 54 | 52 | ||||

| 0.6 | 0.2763 | 0.2831 | 0.2903 | 48 | 47 | 45 | |||||

| 5 | 0.5 | 0.1138 | 0.1161 | 0.1185 | 69 | 67 | 65 | ||||

| 0.6 | 0.2315 | 0.2363 | 0.2413 | 60 | 59 | 58 | |||||

| 5 | 3 | 0.5 | 50 | 0.1368 | 0.1409 | 0.1454 | 55 | 52 | 51 | ||

| 0.6 | 0.2797 | 0.2883 | 0.2974 | 47 | 44 | 42 | |||||

| 4 | 0.6 | 0.2259 | 0.2314 | 0.2373 | 60 | 58 | 56 | ||||

| 0.8 | 0.6936 | 0.7108 | 0.7289 | 42 | 41 | 40 | |||||

| 5 | 0.6 | 0.1894 | 0.1933 | 0.1974 | 75 | 73 | 71 | ||||

| 0.8 | 0.5811 | 0.5931 | 0.6056 | 54 | 53 | 52 | |||||

| 6 | 3 | 0.6 | 60 | 0.2363 | 0.2436 | 0.2512 | 56 | 52 | 50 | ||

| 0.8 | 0.7299 | 0.7523 | 0.7762 | 38 | 36 | 35 | |||||

| 4 | 0.8 | 0.5891 | 0.6037 | 0.619 | 50 | 48 | 47 | ||||

| 1 | 1.4045 | 1.4394 | 1.476 | 42 | 40 | 39 | |||||

| 5 | 0.8 | 0.4939 | 0.5041 | 0.5147 | 63 | 61 | 60 | ||||

| 1 | 1.1765 | 1.2008 | 1.2262 | 51 | 50 | 49 | |||||

Alteration