Linear Guides Standard Block-Low Profile

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part02 CLICK here

Product Description

Linear Guides Standard Block-Low Profile

These linear guides or linear slides are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Rail Length Minimum/Maximum (mm.): 160 and 520

● Assembly Height (mm.): 24, 28, 33, and 42

● Option: Set (Rail + Block) / Block only

● Material: Carbon Steel

[Application]

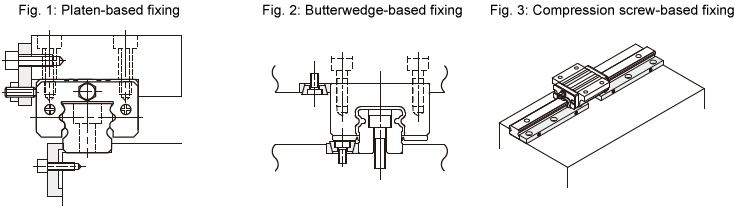

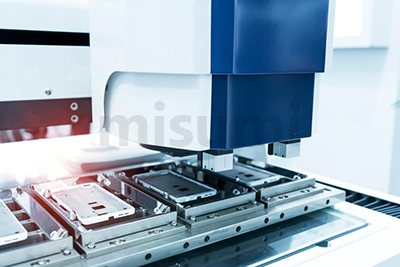

It is used in a variety of machines such as CNC machines, 3D printers, measuring instruments, and so on.

Economy Standard Block Low Profile Linear Guide

- Wide range of sizes available

- Multiple assembly heights available

- Material: Carbon Steel for durability

- Set and Block only options available

- Cost-effective compared to standard products

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Used to support and guide moving parts, Linear Guides make reciprocating linear motion in a specified direction. It is mainly used in mechanical structures with high precision requirements. Rolling steel balls are used instead of intermediate medium between the moving element and the fixed element of the linear guide rail.

Operating Temperature: -20 to 80°C

Operating Temperature: -20 to 80°C Since this product of Linear Guides has no surface treatment, please be sure to take anti-rust measures.

Since this product of Linear Guides has no surface treatment, please be sure to take anti-rust measures. The dimensional tolerance of Length L is ±2 mm.

The dimensional tolerance of Length L is ±2 mm. The kit includes 1 block. For additional blocks, please purchase a single block model.

The kit includes 1 block. For additional blocks, please purchase a single block model.| Type | Component Kit/Single Block |  Material Material |  Hardness Hardness |

| C-ELG | Component Kit | Carbon steel | 58HRC~ |

| C-ELGB | Slider Blick |

Optional heights and lengths are the overall range of this series. Refer to the Specification Table for details.

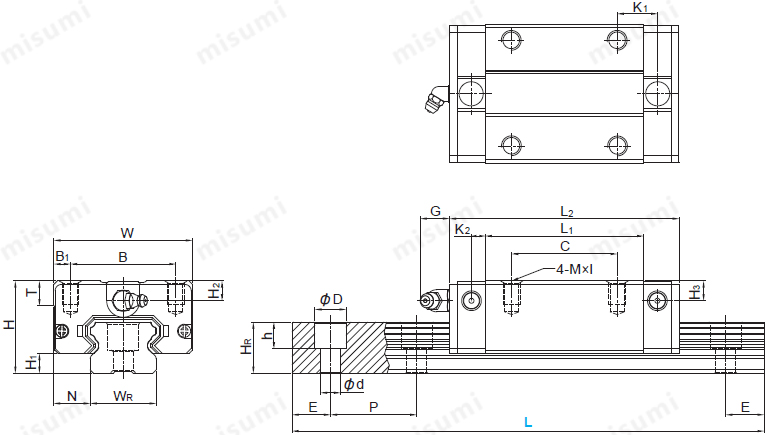

Optional heights and lengths are the overall range of this series. Refer to the Specification Table for details.| Part Number |  Length L Length L(Increments 1mm) | Guide Rail Dimension (mm) | Block Dimension (mm) | |||||||||||||||||||||

Type Type |  Nominal Number Nominal Number | W | B | B1 | L1 | L2 | C | M×ℓ | T | H2 | K1 | K2 | G | WR | N | H | H1 | HR | Countersunk d × D × h | P | E | |||

| C-ELG | 15 | 100~3960 | 34 | 26 | 4 | 39.8 | 59.3 | 26 | M4×6 | 6 | 5.6 | 10.3 | 3.5 | 5 | 15 | 9.5 | 24 | 4.5 | 12.5 | 4.5×7.5×5.3 | 60 | Please refer to the calculation table below | ||

| 20 | 42 | 32 | 5 | 48.1 | 71.2 | 32 | M5×7 | 7.5 | 6 | 12.3 | 4.15 | 12.5 | 20 | 11 | 28 | 6 | 15.5 | 6 ×9.5 × 8.5 | ||||||

| 25 | 48 | 35 | 6.5 | 59 | 87.5 | 35 | M6×9 | 8 | 8 | 17.6 | 4.55 | 12.5 | 23 | 12.5 | 33 | 7 | 18 | 7 × 11 × 9 | ||||||

| 30 | 200~3960 | 60 | 40 | 10 | 70.2 | 101 | 40 | M8×12 | 9 | 21.05 | 6 | 12.5 | 28 | 16 | 42 | 10 | 23 | 9 × 14 × 9 | 80 | |||||

The kit includes 1 block. For additional blocks, please purchase a single block model.

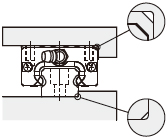

The kit includes 1 block. For additional blocks, please purchase a single block model. The reference surface is set on the side of the block and slide rail with the linear groove. When used, make sure to align the two reference surfaces with each other.

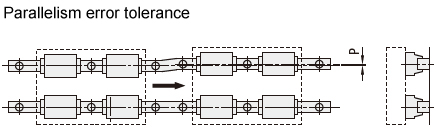

The reference surface is set on the side of the block and slide rail with the linear groove. When used, make sure to align the two reference surfaces with each other. The running parallelism is the value after the slide rail is fixed. (It is not the value before the screws of the slide rail are tightened.)

The running parallelism is the value after the slide rail is fixed. (It is not the value before the screws of the slide rail are tightened.) Since this product has no surface treatment, please be sure to take anti-rust measures.

Since this product has no surface treatment, please be sure to take anti-rust measures. Dimension E of length specified type needs to be calculated. Please refer to "detailed dimension of Dimension L specified type" for calculation method

Dimension E of length specified type needs to be calculated. Please refer to "detailed dimension of Dimension L specified type" for calculation method■ Single Block

| Part Number | Block Dimension (mm) | ||||||||||||

Type Type |  Nominal Number Nominal Number | W | B | B1 | L1 | L2 | C | M×ℓ | T | H2 | K1 | K2 | G |

| C-ELGB | 15 | 34 | 26 | 4 | 39.8 | 59.3 | 26 | M4×6 | 6 | 5.6 | 10.3 | 3.5 | 5 |

| 20 | 42 | 32 | 5 | 48.1 | 71.2 | 32 | M5×7 | 7.5 | 6 | 12.3 | 4.15 | 12.5 | |

| 25 | 48 | 35 | 6.5 | 59 | 87.5 | 35 | M6×9 | 8 | 8 | 17.6 | 4.55 | 12.5 | |

| 30 | 60 | 40 | 10 | 70.2 | 101 | 40 | M8×12 | 9 | 21.05 | 6 | 12.5 | ||

| Nominal Model | Basic Rated Load | Static Allowable Moment | Mass | |||

| C (Dynamic) kN | Co (Static) kN | MA・MB kN-m | MC kN-m | Blocks kg | Guide Rails kg/m | |

| 15 | 7.83 | 16.19 | 0.1 | 0.13 | 0.15 | 1.25 |

| 20 | 10.31 | 21.13 | 0.16 | 0.22 | 0.24 | 2.08 |

| 25 | 16.27 | 32.4 | 0.32 | 0.38 | 0.41 | 2.67 |

| 30 | 23.7 | 47.46 | 0.55 | 0.68 | 0.76 | 4.35 |

■ L Detailed dimension of dimension specified type

Dimension L specified type cuts both ends of the rail equally. Refer to the table below for the number of mounting holes (M) of the slide rail at this time.

In addition, E dimension is calculated with the formula below

| Nominal Number | 15 | 20 | 25 | 30 | Number of Mounting Holes M |

| L | 100~131 | 100~139 | 100~141 | - | 2 |

| 132~191 | 140~199 | 142~201 | 200~279 | 3 | |

| 192~251 | 200~259 | 202~261 | 280~343 | 4 | |

| 252~311 | 260~319 | 262~321 | 344~423 | 5 | |

| 312~371 | 320~379 | 322~381 | 424~503 | 6 | |

| 372~431 | 380~439 | 382~441 | 504~583 | 7 | |

| 432~491 | 440~499 | 442~501 | 584~663 | 8 | |

| 492~551 | 500~559 | 502~561 | 664~743 | 9 | |

| 552~611 | 560~619 | 562~621 | 744~823 | 10 | |

| 612~671 | 620~679 | 622~681 | 824~903 | 11 | |

| 672~731 | 680~739 | 682~741 | 904~983 | 12 | |

| 732~791 | 740~799 | 742~801 | 984~1063 | 13 | |

| 792~851 | 800~859 | 802~861 | 1064~1143 | 14 | |

| 852~911 | 860~919 | 862~921 | 1144~1223 | 15 | |

| 912~971 | 920~979 | 922~981 | 1224~1303 | 16 | |

| 972~1031 | 980~1039 | 982~1041 | 1304~1383 | 17 | |

| 1032~1091 | 1040~1099 | 1042~1101 | 1384~1463 | 18 | |

| 1092~1151 | 1100~1159 | 1102~1161 | 1464~1543 | 19 | |

| 1152~1211 | 1160~1219 | 1162~1221 | 1544~1623 | 20 | |

| 1212~1271 | 1220~1279 | 1222~1281 | 1624~1703 | 21 | |

| 1272~1331 | 1280~1339 | 1282~1341 | 1704~1783 | 22 | |

| 1332~1391 | 1340~1399 | 1342~1401 | 1784~1863 | 23 | |

| 1392~1451 | 1400~1459 | 1402~1461 | 1864~1943 | 24 | |

| 1452~1511 | 1460~1519 | 1462~1521 | 1944~2023 | 25 | |

| 1512~1571 | 1520~1579 | 1522~1581 | 2024~2103 | 26 | |

| 1572~1631 | 1580~1639 | 1582~1641 | 2104~2183 | 27 | |

| 1632~1691 | 1640~1699 | 1642~1701 | 2184~2263 | 28 | |

| 1692~1751 | 1700~1759 | 1702~1761 | 2264~2343 | 29 | |

| 1752~1811 | 1760~1819 | 1762~1821 | 2344~2423 | 30 | |

| 1812~1871 | 1820~1879 | 1822~1881 | 2424~2503 | 31 | |

| 1872~1931 | 1880~1939 | 1882~1941 | 2504~2583 | 32 | |

| 1932~1991 | 1940~1999 | 1942~2001 | 2584~2663 | 33 | |

| 1992~2051 | 2000~2059 | 2002~2061 | 2664~2743 | 34 | |

| P | 60 | 80 | |||

| Nominal Model | 15 | 20 | 25 | 30 | Number of Mounting Holes M |

| L | 2052~2111 | 2060~2119 | 2062~2121 | 2744~2823 | 35 |

| 2112~2171 | 2120~2179 | 2122~2181 | 2824~2903 | 36 | |

| 2172~2231 | 2180~2239 | 2182~2241 | 2904~2983 | 37 | |

| 2232~2291 | 2240~2299 | 2242~2301 | 2984~3063 | 38 | |

| 2292~2351 | 2300~2359 | 2302~2361 | 3064~3143 | 39 | |

| 2352~2411 | 2360~2419 | 2362~2421 | 3144~3223 | 40 | |

| 2412~2471 | 2420~2479 | 2422~2481 | 3224~3303 | 41 | |

| 2472~2531 | 2480~2539 | 2482~2541 | 3304~3383 | 42 | |

| 2532~2591 | 2540~2599 | 2542~2601 | 3384~3463 | 43 | |

| 2592~2651 | 2600~2659 | 2602~2661 | 3464~3543 | 44 | |

| 2652~2711 | 2660~2719 | 2662~2721 | 3544~3623 | 45 | |

| 2712~2771 | 2720~2779 | 2722~2781 | 3624~3703 | 46 | |

| 2772~2831 | 2780~2839 | 2782~2841 | 3704~3783 | 47 | |

| 2832~2891 | 2840~2899 | 2842~2901 | 3784~3863 | 48 | |

| 2892~2951 | 2900~2959 | 2902~2961 | 3864~3943 | 49 | |

| 2952~3011 | 2960~3019 | 2962~3021 | 3944~3960 | 50 | |

| 3012~3071 | 3020~3079 | 3022~3081 | - | 51 | |

| 3072~3131 | 3080~3139 | 3082~3141 | 52 | ||

| 3132~3191 | 3140~3199 | 3142~3201 | 53 | ||

| 3192~3251 | 3200~3259 | 3202~3261 | 54 | ||

| 3252~3311 | 3260~3319 | 3262~3321 | 55 | ||

| 3312~3371 | 3320~3379 | 3322~3381 | 56 | ||

| 3372~3431 | 3380~3439 | 3382~3441 | 57 | ||

| 3432~3491 | 3440~3499 | 3442~3501 | 58 | ||

| 3492~3551 | 3500~3559 | 3502~3561 | 59 | ||

| 3552~3611 | 3560~3619 | 3562~3621 | 60 | ||

| 3612~3671 | 3620~3679 | 3622~3681 | 61 | ||

| 3672~3731 | 3680~3739 | 3682~3741 | 62 | ||

| 3732~3791 | 3740~3799 | 3742~3801 | 63 | ||

| 3792~3851 | 3800~3859 | 3802~3861 | 64 | ||

| 3852~3911 | 3860~3919 | 3862~3921 | 65 | ||

| 3912~3960 | 3920~3960 | 3922~3960 | 66 | ||

| P | 60 | 80 | |||

| Rail Length (mm) | Accuracy grade (μm) |

| 100-200 | 14 |

| 200-300 | 15 |

| 300-500 | 17 |

| 500-700 | 20 |

| 700-900 | 22 |

| 900-1100 | 24 |

| 1100-1500 | 26 |

| 1500-1900 | 28 |

| 1900-2500 | 31 |

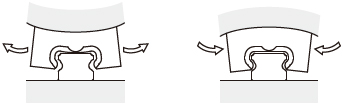

Feature of Linear Guides 2: The slide rail and the slider are in contact with each other through the rolling ball, so the shaking is small, and it is suitable for equipment with precision requirements.

Feature of Linear Guides 3: Due to a point-to-surface contact, the frictional resistance is small, and it can perform subtle movements to achieve device positioning.

Feature of Linear Guides 4: It has a large allowable load because the force on the rotating surface is dispersed due to the rolling groove of the ball.

Feature of Linear Guides 5: It is suitable for high speed motion because it is not easy to produce friction heat when operating and not easily deformed by heat.

① Operating distance life

The load shall be calculated before using a linear guide. It is not easy to calculate the load during the linear reciprocating motion, because there may be vibration or impact during the motion, requiring a full consideration to the distribution of vibration or impact relative to the linear guide. Operating temperature and other factors also have great influence on the service life. Taking all these conditions into account, the above calculation formula is changed into the following one.

here.

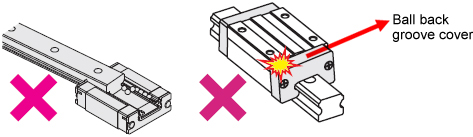

here.① MISUMI's Linear Guides is installed with a retainer. Although the ball is not easy to fall off when the slide block is removed, the ball may fall off if the slider is removed from the rail at high speed, or tilted into the slide rail. Please disassemble the slider with care.

② Be sure to avoid colliding the ball back groove cover, otherwise it will affect the ball cycling, resulting in poor sliding.

③ If you have anti-rust requirements, please choose the Low Temp. Black Chrome Plating Surface Treatment or Stainless Steel SUS440C products.

■ About maintenance of Linear Guides (supply of grease)

① Grease forms an oil film on the surface of the linear guide ball and rail surface to effectively reduce friction and prevent sintering.

Decrease and aging of grease will greatly affect the life of the linear guide, so please add grease at the right time according to the service conditions.

MISUMI's linear guides are sealed with the greases at the time of shipment, so they can be used directly.

② Recommend grease filling interval:

The specific maintenance time shall be adjusted according to the actual situation. It is recommended to check the grease condition once every 100 km.

* The above is the grease filling interval under the moving distance standard. Depending on the operating environment, the grease injection interval must be shortened appropriately when the grease is aging and dirty.

② Keep the flatness of the workpiece mounting surface at about 5μ, otherwise the slider will be slightly deformed

③ Whether the error values of guide parallelism and fitting height are within the allowable installation values

④ Use the standard of Linear Guides

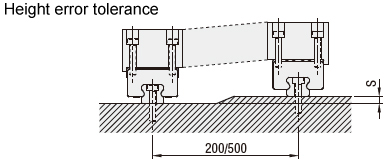

Installation method of Linear Guides Click

here for the detailed installation method

here for the detailed installation method

Feature of Linear Guides 1: Suitable for medium precision and medium frequency driving and positioning.

Feature of Linear Guides 2: A linear guide is configured in the center to achieve miniaturization.

For details, click

here

here| Medical | Smart phone | |

|  | |

| Robotics | Electronic & Electrical Appliances | |

|  |

| Miniature linear guide Standard light preloading type | Miniature linear guide Wide slide rail type | Heavy Load linear guide | ||

|  |  | ||

| Typical Linear Guides model: SSEB10-55 | Typical Linear Guides model: SSEBW12-200 | Typical Linear Guides model: SXR24-280 |

here

here