Precision Ball Screws Shaft Dia.20 Lead 5/10/20 Accuracy Grade C5

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

- Precision Ball Screws Shaft Dia.20 Lead 5/10/20 Accuracy Grade C5 from MISUMI.

- Precision Ball Screws have a shaft diameter of 20 mm and are available in three different lead sizes: 5mm, 10mm or 20mm.

- The accuracy grade option for this product is C5.

- The overall length of the shaft screw can be customized to fit a range of configurations, from 200mm to 900mm, in 1mm increments.

- The lead twisting direction for this product is right-handed.

- The screw shaft is made of S55C while the nut is made of SCM420.

Economy Precision Ball Screws 20 Lead

- High accuracy grade C5 ensures superior precision

- Shaft diameter and lead options available in multiple sizes

- Customizable screw lengths within a specified range in 1mm increments

- Made of durable S55C screw shaft and SCM420 nut material

- Ideal for FA automation equipment positioning mechanisms

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview

1. This series of products is the C5 Precision Ball Screw with the shaft diameter of 20 and lead of 5/10/20.2. With small backlash of the nut, it has higher precision and lower noise than the rolled Ball Screw, but the motor starting torque will increase.

3. It is more suitable for positioning mechanisms in FA automation equipment.

4. The screw shaft end is machined according to standard specifications. If the shaft end requires alteration, it should be specified according to the catalog.

| Model No./Specification Example | |||||

| Model No. | Accuracy | Shaft Dia. | Lead | Total Length | |

| MISUMI Standard Product | BSS2010-300 | C5 | 20 | 10 | 300 |

| C-Value | C-BSSA2010-300 | ||||

| Economy Series | C-KBS2010-300 | C5 equivalent*1 | |||

■ Lead Accuracy

■ Fluctuation Tolerances

Unit: μm

| Accuracy Class | C3 | C5 | ||

| Item | Fluctuation (300) (2) | Fluctuation (2π) (3) | Fluctuation (300) (2) | Fluctuation (2π) (3) |

| Fluctuation Tolerance | 8 | 6 | 18 | 8 |

(2) Fluctuation for an arbitrary length of 300mm within the effective thread length of the screw shaft

(3) Fluctuation for an arbitrary 1 rotation (2π rad) within the effective thread length of the screw shaft

■ Mounting Part Accuracy

Ground Ball Screw

| Model | Lead | Screw Length | (1)(2) Runout Tolerance (Max.) | (3) Runout Tolerance (Max.) | (4)(5) Perpendicularity Tolerance (Max.) | (6) Perpendicularity Tolerance (Max.) | (7) Perpendicularity Tolerance (Max.) | Axial Clearance | ||||||||||||||

| Type | Screw Shaft Outer Dia. | Min. | Max. | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | |

| C-KBS | 8 | 2 | 100 | 210 | 0.011 | 0.014 | 0.011 | 0.014 | 0.005 | 0.02 *Reference value | 0.01 | Not guaranteed | 0.012 | Not guaranteed | 0.005 or less | 0.008 or less | 0.008 or less | |||||

| 10 | 2/4 | 100 | 350 | |||||||||||||||||||

| 12 | 4/10 | 150 | 500 | |||||||||||||||||||

| 15 | 5/10/20 | 150 | 1100 | 0.012 | 0.012 | 0.011 | 0.015 | 0.015 or less | 0.015 or less | |||||||||||||

| 20 | 5/10/20 | 200 | 1500 | |||||||||||||||||||

| 25 | 5/10/25 | 300 | 1500 | 0.013 | 0.013 | 0.013 | 0.019 | |||||||||||||||

This measurement item is affected by Total Run-out (8) of the Screw Shaft, and so it must be corrected.

(3) Radial runout of drive component interface surface in relation to screw shaft support axis.

(4)・(5) Perpendicularity of shaft's bearing shoulders in relation to screw shaft support axis.

(6) Perpendicularity of ball nut mounting flange surface (datum) in relation to screw shaft axis.

(7) Radial runout of ball nut body outer circumference in relation to screw shaft axis.

Dimensional Drawing

| Type | Accuracy grade | Screw diameter | Lead | Screw shaft | Nut | ||||

Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment | ||||

| C-KBS | C5 | 20 | 5·10·20 | Equivalent to S55C | High frequency quenching 58 to 62HRC | - | Equivalent to SCM420 | Carburized 58 to 62HRC | - |

| Part Number of Ball Screw |  L L(1mm increments) | Y | Number of cycles | Basic Rated Load | Axial Clearance | Twisting Direction | Screw support unit (Sold separately) | |||||

Type Type |  Screw Shaft O.D. Screw Shaft O.D. |  Lead Lead | C (Dynamic) kN | C (Static) kN | Shape | Fixed side model | Support side model | |||||

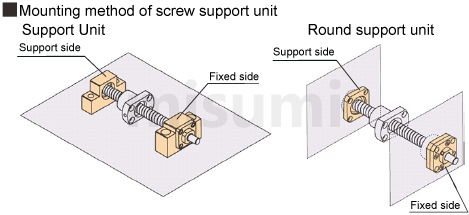

| C-KBS | 20 | 05 | 200 to 1500 | L-82 | 4 laps | 4.3 | 10.3 | 0.015 or Less | Right | Square Type | C-TEK15 | C-TEF15 |

| Round type | C-TFK15 | C-TFF15 | ||||||||||

| 10 | 3 laps | 4.9 | 10.6 | Square Type | C-TEK15 | C-TEF15 | ||||||

| Round type | C-TFK15 | C-TFF15 | ||||||||||

| 20 | 1.8 laps | 4.3 | 10.3 | Square Type | C-TEK15 | C-TEF15 | ||||||

| Round type | C-TFK15 | C-TFF15 | ||||||||||

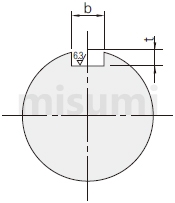

| Shaft Dia. | b | t | ||

| Reference dimension | Tolerance (N9) | Reference dimension | Tolerance | |

| 6 to 7 | 2 | -0.004 -0.029 | 1.2 | +0.1 0 |

| 8 to 10 | 3 | 1.8 | ||

| 11 to 12 | 4 | 0 -0.03 | 2.5 | |

| 13 to 17 | 5 | 3.0 | ||

| 18 to 20 | 6 | 3.5 | ||

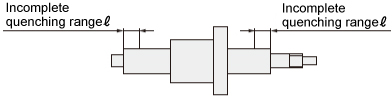

| Screw diameter | Incomplete quenching range ℓ (max) |

| φ8, φ10 | 5mm |

| φ12, φ15 | 10mm |

| φ20, φ25 | 15mm |

| Type | Screw Shaft O.D. | Runout tolerance G (Max.) | Incomplete Hardened Area (ℓ) | ||||||||||

| ~125 | 126~200 | 201~315 | 316~400 | 401~500 | 501~630 | 631~800 | 801~1000 | 1001~1250 | 1251~1600 | 1601~2000 | |||

| E-TBS | 4 | 0.060 | 0.075 | - | - | - | - | - | - | - | - | - | 5 |

| 6 | 0.075 | 0.075 | - | - | - | - | - | - | - | - | - | ||

| C-TBSE C-TBSB | 8 | 0.100 | 0.140 | 0.210 | 0.270 | - | - | - | - | - | - | - | 10 |

| 10 | - | 0.120 | 0.160 | 0.210 | 0.270 | 0.350 | - | - | - | - | - | ||

| 12 | - | 0.120 | 0.160 | 0.210 | 0.270 | 0.350 | 0.480 | - | - | - | - | ||

| 15 | - | 0.110 | 0.130 | 0.160 | 0.200 | 0.250 | 0.320 | 0.420 | 0.550 | - | - | ||

| 20 | - | 0.110 | 0.130 | 0.160 | 0.200 | 0.250 | 0.320 | 0.420 | 0.550 | 0.730 | 0.730 | 15 | |

| 25 | - | 0.110 | 0.110 | 0.130 | 0.160 | 0.190 | 0.230 | 0.300 | 0.380 | 0.500 | 0.690 | ||

| 32 | - | - | 0.110 | 0.130 | 0.160 | 0.190 | 0.230 | 0.300 | 0.380 | 0.500 | 0.690 | 20 | |

| E-KBS | 4 | 0.050 | - | - | - | - | - | - | - | - | - | - | 5 |

| 6 | 0.050 | 0.050 | - | - | - | - | - | - | - | - | - | ||

| C-KBS | 8 | 0.060 | 0.075 | 0.100 | - | - | - | - | - | - | - | - | |

| 10 | 0.055 | 0.065 | 0.080 | 0.100 | - | - | - | - | - | - | - | ||

| 12 | - | 0.065 | 0.080 | 0.100 | 0.120 | - | - | - | - | - | - | 10 | |

| 15 | - | 0.060 | 0.070 | 0.080 | 0.095 | 0.110 | 0.140 | 0.170 | 0.210 | - | - | ||

| 20 | - | 0.060 | 0.070 | 0.080 | 0.095 | 0.110 | 0.140 | 0.170 | 0.210 | 0.270 | - | 15 | |

| 25 | - | - | 0.060 | 0.070 | 0.080 | 0.090 | 0.100 | 0.130 | 0.170 | 0.210 | - | ||

| E-KLR | 4 | 0.050 | 0.050 | - | - | - | - | - | - | - | - | - | 5 |

| 8 | 0.065 | 0.075 | 0.100 | - | - | - | - | - | - | - | - | ||

| 10 | 0.065 | 0.065 | 0.080 | 0.100 | - | - | - | - | - | - | - | ||

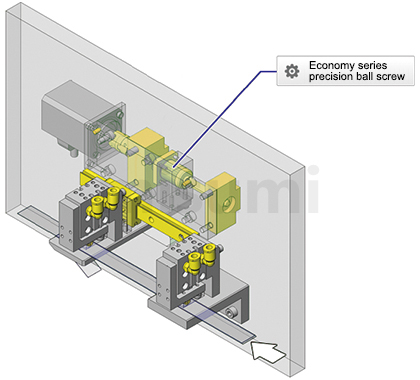

Product Features

1. Drawing-based machining is no longer required, saving the time for drawing.2. Ball Screw When used in combination with Economy series support unit, it has a better effect.

3. The total length of screw shaft can be specified in 1 mm increments. With abundant shaft end specifications, it is possible to specify alterations for different applications.

Example of Use

Precautions

● The noise value of the Ball Screw after assembly is not guaranteed.

● Although lithium soap-based grease has been applied at the factory, it is required to apply new grease every 2~3 months as standard after receiving the goods, otherwise the normal use will be affected. For details, see Catalog P687.

● In operation, if there is too much noise or sharp and harsh sound, please make sure that the installation accuracy of the screw and the specifications of peripheral components such as motors and couplings are appropriate.

Do not let the nut exceed the movement range of the Ball Screw nut, or screw out of the screw shaft, otherwise the ball will fall off and the ball cycling parts will be damaged.

● Ball Screws and nuts placed with an inclination may fall due to weight. Please be careful.

● This product is a machined type, so there will be knife patterns and color difference in its appearance. Small scratches or color changes without affecting the use and main function are of a normal phenomenon. Please feel free to use.

■ Precautions of the Ball Screw and peripheral parts design and assembly

The Ball Screw is a component that only bears axial load. If it is subjected to radial load or moment load, poor sliding, vibration or abnormal noise may occur, shortening its service life.

The reason that the Ball Screw bears radial load and moment load is the axis deviation and parallelism error of the surrounding parts. Therefore, it is necessary to correctly design and assemble the peripheral parts of the Ball Screw to prevent errors.

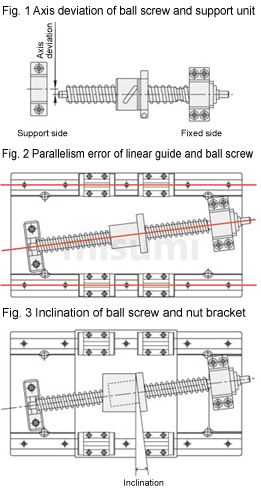

● Axis deviation of Ball Screw and support unit (Fig. 1)

- Axis deviation is the deviation of the Ball Screw fixed by the fixed side support unit and the bearing of the supporting side support unit.

-The allowable value of the axis deviation is 20μ or less (reference value)

●Parallelism between Ball Screw and linear guide (Diagram 2)

- Parallelism error refers to the inclination of the Ball Screw in the up-down or left-right direction with respect to the reference of the linear guide.

-The allowable value of inclination is below 1/2000 (Diagram 3)

●Precautions of assembly

If you notice abnormal noises during the operation of the Ball Screw or jamming during movement after assembly, please loosen the connections of the parts before proceeding. Adjust and reassemble after moving smoothly.

- Error in the left and right direction of the support unit (Fig. 1)

- Parallel error of linear guide and Ball Screw (Fig. 2)

- Fixing of workbench and nut bracket

- Fixing of Ball Screw nut and nut bracket

| ・Removal of nut is prohibited | ・No impact on the nut | ・Be careful of falling due to weight |

|  |  |

| ・Checking for reverse action | ・Pay attention to intrusion of foreign objects | ・Nut overstroke is prohibited |

|  |  |

| ||