Spring Plungers Stainless Steel

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

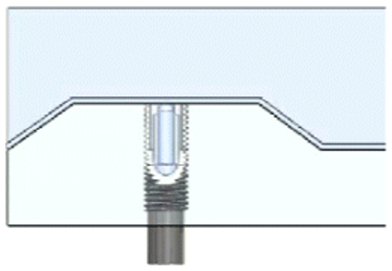

- Spring Plungers Stainless Steel

- C-PJLW and C-PJHW are in the MISUMI economy series ball plungers.

- Body Material: Equivalent Stainless Steel SUS303.

- Pin Material: Stainless Steel SUS303.

- Pin Hardness: 20HRC~

- Spring Material: Stainless Steel SUS304

- The operating Temperature: -30 to 260℃

- Mounting Thread size: 3, 4, 5, 6, 8, 10 and 12 mm.

- Stroke (S): 2, 3, 4, 5 and 10 mm.

- Load Classification: (C-PJLW) Light Load and (C-PJHW) Heavy Load.

- Wrench Hole Shape: Hex.

♢ The spring plunger is also known as the positioning column, ball screw, spring screw, etc. It is a product involving vertical stroke, in which the front pin is pressed till the pin sinks into the body and then the front pin can be ejected through the built-in spring. It can be used in mold release, workpiece lifting and positioning, etc., which can be widely applied in medium and low-precision mechanical devices, fixtures, molds, automation machines, etc.

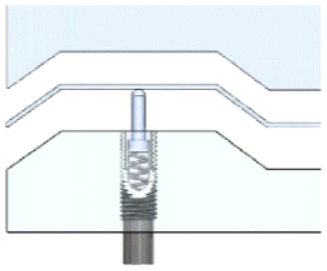

Type:E-L□□□□

| Load Classification | Type | Body | Pin | Spring | ||

Material Material |  Material Material |  Hardness Hardness |  Material Material | |||

| Stainless Steel Convex Pin | Light Load | C-PJLW C-PJHW | SUS303 | SUS303 | 20HRC~ | SUS304 |

| Heavy Load | ||||||

| Load Classification | Type | Body | Pin | Spring | ||||

Material Material |  Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material | ||||

| Stainless Steel Convex Pin | Ultra Light Load | E-LPJLSW | SUS303 | SUS420F | 40~50HRC | Nickel plating | SUS304 | |

| Ultra Heavy Load | E-LPJLXW | |||||||

| Resin Convex Pin | Ultra Light Load | E-LPJLSK | POM | - | - | |||

| Light Load | E-LPJLK | |||||||

| Heavy Load | E-LPJHK | |||||||

| Ultra Heavy Load | E-LPJXK | |||||||

| Part Number |  Stroke S Stroke S | d | ℓ | L | B | Light Load | Heavy Load | |||||||

Type Type |  O.D. M O.D. M(Coarse Thread) | Load (N) | Load (N) | |||||||||||

| min. | max. | min. | max. | |||||||||||

| C-PJLW(Light Load) C-PJHW(Heavy Load) | 3 | 3 | 1 | 15 | 15 | 0.9 | 0.3 | 1.5 | 0.6 | 3 | ||||

| 4 | 2 | 1.6 | 1.5 | 15 | 1.3 | 0.5 | 2 | 2 | 10 | |||||

| 4 | 24 | 24 | 1 | 5 | 2 | 10 | ||||||||

| 5 | 3 | 2 | 20 | 20 | 1.5 | 2 | 10 | 5 | 18 | |||||

| 5 | 27 | 27 | 3 | 15 | 8 | 25 | ||||||||

| 6 | 3 | 2.5 | 25 | 25 | 2 | 3 | 15 | 8 | 25 | |||||

| 5 | 30 | 30 | 5 | 20 | 10 | 30 | ||||||||

| 8 | 3 | 3.1 | 25 | 25 | 2.5 | 5 | 20 | 10 | 30 | |||||

| 5 | 27 | 27 | 8 | 25 | 13 | 40 | ||||||||

| 10 | 5 | 3.8 | 30 | 30 | 3 | 5 | 20 | 15 | 45 | |||||

| 12 | 10 | 5.5 | 35 | 43 | 4 | 8 | 25 | 18 | 50 | |||||

The min. load represents the initial load, and the max. load represents the load at the maximum press-in limit of convex pin.

The min. load represents the initial load, and the max. load represents the load at the maximum press-in limit of convex pin. There is a groove for front end riveting.

There is a groove for front end riveting. No anti-loosening treatment is applied.

No anti-loosening treatment is applied.| Part Number |  Stroke S Stroke S | d | ℓ | L | B | Ultra Light Load | Light Load | Heavy Load | Ultra Heavy Load | |||||

| Type |  O.D. M O.D. M(Coarse Thread) | Load (N) | Load (N) | Load (N) | Load (N) | |||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | |||||||

| (Stainless Steel Convex Pin) E-LPJLSW E-LPJXW (Resin Convex Pin) E-LPJLSK E-LPJLK E-LPJHK E-LPJXK | 3 | 1.5 | 1 | 15 | 15 | 0.9 | 0.12 | 0.4 | 0.4 | 1.3 | 0.8 | 2.94 | 1.1 | 3.42 |

| 3 | 15 | 15 | 0.12 | 0.4 | 0.2 | 1.3 | 0.6 | 2.93 | 0.8 | 3.41 | ||||

| 4 | 2 | 1.6 | 15 | 15 | 1.3 | 0.27 | 0.65 | 0.9 | 2 | 2 | 8.8 | 6.1 | 13.8 | |

| 4 | 24 | 24 | 0.18 | 0.65 | 0.6 | 2.1 | 1.9 | 8.75 | 5.8 | 13.6 | ||||

| 5 | 3 | 2 | 20 | 20 | 1.5 | 0.4 | 3 | 1.4 | 9.7 | 2.7 | 16.3 | 6.8 | 22 | |

| 5 | 27 | 27 | 0.35 | 3 | 1.1 | 10.3 | 1 | 17.1 | 5.7 | 21.5 | ||||

| 6 | 3 | 2.5 | 25 | 25 | 2 | 1.8 | 3.05 | 6 | 9.8 | 8 | 26.4 | 15.8 | 35.6 | |

| 5 | 30 | 30 | 1.5 | 3.05 | 3.4 | 9.86 | 4.4 | 26.6 | 12.9 | 34.4 | ||||

| 8 | 3 | 3.1 | 25 | 25 | 2.5 | 1.9 | 3.15 | 6 | 9.9 | 14.7 | 27 | 21.9 | 36.3 | |

| 5 | 27 | 27 | 1.4 | 3.15 | 4 | 9.83 | 6.7 | 26.6 | 14.7 | 34.5 | ||||

| 10 | 5 | 3.8 | 30 | 30 | 3 | 1.6 | 4.6 | 5.7 | 14.7 | 8.2 | 45.7 | 24.5 | 58.6 | |

| 10 | 30 | 43 | 1.6 | 4.6 | 4.4 | 14.7 | 6.2 | 45.1 | 19.8 | 58.7 | ||||

| 12 | 5 | 5.5 | 30 | 30 | 4 | 1.7 | 4.7 | 5.8 | 14.7 | 18.2 | 49 | 34.9 | 63.6 | |

| 10 | 35 | 43 | 1.6 | 4.7 | 5 | 14.7 | 8.2 | 49.1 | 25.5 | 63.6 | ||||

| 15 | 35 | 51 | 1.8 | 4.7 | 6.9 | 14.7 | 7.5 | 48.9 | 20.1 | 63.7 | ||||

| 16 | 10 | 8 | 35 | 57 | 5 | 2.8 | 10.8 | 9.2 | 34.2 | 18.9 | 68.6 | 38.7 | 88.4 | |

| 15 | 35 | 57 | 2.6 | 10.8 | 8.6 | 34.4 | 14.4 | 68.6 | 33.9 | 88.1 | ||||

| 20 | 35 | 67 | 2 | 11 | 7.1 | 34.4 | 4.2 | 68.6 | 25.4 | 88.1 | ||||

♢ It is made of all stainless steel without painting and coloring, so it is suitable for equipment with high requirements on the surface.

♢The front end has a wrench slot, and the bottom end has a hex socket mounting hole, which facilitates installation.

♢ The stroke can be fine-tuned correspondingly to the screw-in depth.

♢ The spring plunger is a product involving vertical stroke. It can be used in mold release, workpiece lifting and positioning, etc., which can be widely applied in medium and low-precision mechanical devices, fixtures, molds, automation machines, etc.