Timing Belts HTD5M

Caution

- Some products in [Timing Belts HTD5M] are scheduled to be discontinued on 31/10/2025. However, we will continue to sell them until stock runs out.

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

・ Product type: Timing Belts HTD5M type.

・ Belt Width [mm]: 9, 15, 25, 30

・ Circumference Length [mm]: 175 ・ 4260

・ Number of Teeth: 35 – 852

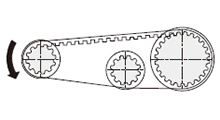

・ Timing pulleys and belts are commonly used to transmit rotational power from motors. They achieve driving and transmission by engaging the teeth of the pulleys with the belts.

・ This is an economy item; The price is cheaper than the MISUMI standard product.

Economy HTD 5M Timing Belt

- Compact Design for Space-Saving Applications. With a smaller tooth pitch and a wide range of compact sizes, our HTD 5M belts are perfect for applications with limited space.

- The unique arc tooth profile delivers higher power transmission compared to traditional trapezoidal profiles, ensuring optimal efficiency and reduced energy loss.

- Engineered to function reliably in specified temperature range.

- The arc tooth profile contributes to minimal vibration and noise generation, creating a smoother and quieter operation.

- Suitable for a broad spectrum of industries and equipment, including automation, packaging, and general machinery, these belts demonstrate their adaptability.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Timing Belt Product Overview

Driving and transmission are realized through the engagement between the teeth of timing pulleys and Timing Belts.

Local production in China delivers MISUMI quality at low price.

Timing Belt Product Features

Feature 1: The arc tooth profile has higher transmission power in comparison with the trapezoidal tooth.

Feature 2: Economical and maintenance free.

Feature 3: The tooth rubber adopts chloroprene to protect core wire from dirt, grease, and wet environments.

Feature 4:·Have certain conductivity.

Feature 5:·Recommended Operating Temperature Range: -10 to 90℃.

Timing Belt Dimensional Drawing

Timing Belt Specifications Overview

Material Material | |

| ① Rear rubber | Chloroprene |

| ② Tooth rubber | |

| ③ Core wire | Glass Fiber |

| ④ Backing cloth | Nylon canvas |

| Types | Tooth pitch | Lr | H | h | PLD |

| H5M | 5 | 3.05 | 3.8 | 2.06 | 0.5715 |

Belt circumference length is core wire length.

Belt circumference length is core wire length. Belt Operating Temperature Range: -10 to 90℃.

Belt Operating Temperature Range: -10 to 90℃. The model engraved on the back of the product is the manufacturer model.

The model engraved on the back of the product is the manufacturer model. MISUMI makes no commitment to this product brand.

MISUMI makes no commitment to this product brand. For the transmission capacity and calculation and design method of economy series Timing Belt, please refer to the national standard (GB) design manual.

For the transmission capacity and calculation and design method of economy series Timing Belt, please refer to the national standard (GB) design manual.Example of Timing Belt Use

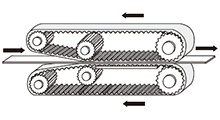

| Timing Belt Usage Method Example Drawing | Instructions for use of timing wheel and Timing Belt |

| ①Driving (The driven wheel is driven by the driving wheel for transmission) |

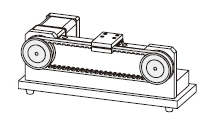

| ②Transmission (Used for repeated motion with the object not rotating and high requirements on positioning accuracy) |

| Timing Belt Usage Method Example Drawing | Instructions for use of timing wheel and Timing Belt |

| ③Conveyance (Plates are conveyed by two timing toothed belts) |

| ④Traction transmission (Workpieces are clamped and transmitted by the belt) |

Timing Belt Application Industries

| Food | Semiconductor | Smart phone | ||

|  |  | ||

| Automotive | Electronic & Electrical Appliances | Medical | ||

|  |  |

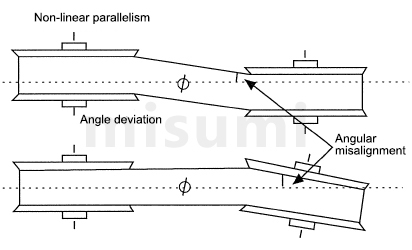

Timing Belt Usage Method

Timing Belt Precautions

Do not use in direct contact with water, solvent, oil, acid, alkali, UV, ozone, etc.③ Please avoid using or keeping at extreme high or low temperatures beyond the operating temperature range, or in humid environments.

④ During installation and maintenance, be sure to cut off the power supply and confirm that the machine is completely stopped before proceeding.

⑤ When there may be impurities, be sure to set the guard.

Timing Belt Related Products

| Timing Belts S3M | Timing Belts S5M | Timing Pulleys S3M | ||

|  |  | ||

| Reference model: C-HTBN141S3M-60 | Reference model: C-HTBN350S5M-150 | Reference model: C-HTPA18S3M100-A-P5 |

■Type H5M (Tooth Pitch: 5 mm)

| Belt Number | Belt Nominal Width | Number of Teeth | Belt Circumference Length (mm) |

| 175H5M | 90 (9mm) 150 (15mm) 250 (25mm) 300 (30mm) | 35 | 175 |

| 180H5M | 36 | 180 | |

| 185H5M | 37 | 185 | |

| 200H5M | 40 | 200 | |

| 210H5M | 42 | 210 | |

| 215H5M | 43 | 215 | |

| 220H5M | 44 | 220 | |

| 225H5M | 45 | 225 | |

| 230H5M | 46 | 230 | |

| 235H5M | 47 | 235 | |

| 245H5M | 49 | 245 | |

| 250H5M | 50 | 250 | |

| 255H5M | 51 | 255 | |

| 260H5M | 52 | 260 | |

| 265H5M | 53 | 265 | |

| 270H5M | 54 | 270 | |

| 275H5M | 55 | 275 | |

| 280H5M | 56 | 280 | |

| 285H5M | 57 | 285 | |

| 290H5M | 58 | 290 | |

| 295H5M | 59 | 295 | |

| 300H5M | 60 | 300 | |

| 305H5M | 61 | 305 | |

| 310H5M | 62 | 310 | |

| 320H5M | 64 | 320 | |

| 325H5M | 65 | 325 | |

| 330H5M | 66 | 330 | |

| 335H5M | 67 | 335 | |

| 340H5M | 68 | 340 | |

| 345H5M | 69 | 345 | |

| 350H5M | 70 | 350 | |

| 355H5M | 71 | 355 | |

| 360H5M | 72 | 360 | |

| 365H5M | 73 | 365 | |

| 370H5M | 74 | 370 | |

| 375H5M | 75 | 375 | |

| 380H5M | 76 | 380 | |

| 385H5M | 77 | 385 | |

| 390H5M | 78 | 390 | |

| 395H5M | 79 | 395 | |

| 400H5M | 80 | 400 | |

| 405H5M | 81 | 405 | |

| 410H5M | 82 | 410 | |

| 420H5M | 84 | 420 | |

| 425H5M | 85 | 425 | |

| 430H5M | 86 | 430 | |

| 435H5M | 87 | 435 | |

| 440H5M | 88 | 440 | |

| 450H5M | 90 | 450 | |

| 460H5M | 92 | 460 | |

| 465H5M | 93 | 465 | |

| 470H5M | 94 | 470 | |

| 475H5M | 95 | 475 | |

| 480H5M | 96 | 480 | |

| 490H5M | 98 | 490 | |

| 495H5M | 99 | 495 | |

| 500H5M | 100 | 500 | |

| 505H5M | 101 | 505 | |

| 510H5M | 102 | 510 | |

| 515H5M | 103 | 515 | |

| 520H5M | 104 | 520 | |

| 525H5M | 105 | 525 | |

| 530H5M | 106 | 530 | |

| 535H5M | 107 | 535 | |

| 540H5M | 108 | 540 | |

| 545H5M | 109 | 545 | |

| 550H5M | 110 | 550 | |

| 560H5M | 112 | 560 | |

| 565H5M | 113 | 565 | |

| 570H5M | 114 | 570 | |

| 575H5M | 115 | 575 | |

| 580H5M | 116 | 580 | |

| 585H5M | 117 | 585 | |

| 590H5M | 118 | 590 | |

| 595H5M | 119 | 595 | |

| 600H5M | 120 | 600 | |

| 605H5M | 121 | 605 | |

| 610H5M | 122 | 610 | |

| 615H5M | 123 | 615 | |

| 620H5M | 124 | 620 | |

| 625H5M | 125 | 625 | |

| 630H5M | 126 | 630 | |

| 635H5M | 127 | 635 | |

| 640H5M | 128 | 640 | |

| 645H5M | 129 | 645 | |

| 650H5M | 130 | 650 | |

| 655H5M | 131 | 655 | |

| 660H5M | 132 | 660 | |

| 665H5M | 133 | 665 | |

| 670H5M | 134 | 670 | |

| 675H5M | 135 | 675 | |

| 680H5M | 136 | 680 | |

| 685H5M | 137 | 685 | |

| 690H5M | 138 | 690 | |

| 695H5M | 139 | 695 | |

| 700H5M | 140 | 700 | |

| 710H5M | 142 | 710 | |

| 715H5M | 143 | 715 | |

| 720H5M | 144 | 720 | |

| 725H5M | 145 | 725 | |

| 730H5M | 146 | 730 | |

| 735H5M | 147 | 735 | |

| 740H5M | 148 | 740 | |

| 745H5M | 149 | 745 | |

| 750H5M | 150 | 750 | |

| 755H5M | 151 | 755 | |

| 760H5M | 152 | 760 |

| Belt Number | Belt Nominal Width | Number of Teeth | Belt Circumference Length (mm) |

| 765H5M | 90 (9mm) 150 (15mm) 250 (25mm) 300 (30mm) | 153 | 765 |

| 770H5M | 154 | 770 | |

| 775H5M | 155 | 775 | |

| 780H5M | 156 | 780 | |

| 790H5M | 158 | 790 | |

| 800H5M | 160 | 800 | |

| 805H5M | 161 | 805 | |

| 810H5M | 162 | 810 | |

| 815H5M | 163 | 815 | |

| 820H5M | 164 | 820 | |

| 825H5M | 165 | 825 | |

| 830H5M | 166 | 830 | |

| 835H5M | 167 | 835 | |

| 845H5M | 169 | 845 | |

| 850H5M | 170 | 850 | |

| 860H5M | 172 | 860 | |

| 870H5M | 174 | 870 | |

| 890H5M | 178 | 890 | |

| 900H5M | 180 | 900 | |

| 920H5M | 184 | 920 | |

| 925H5M | 185 | 925 | |

| 930H5M | 186 | 930 | |

| 935H5M | 187 | 935 | |

| 940H5M | 188 | 940 | |

| 950H5M | 190 | 950 | |

| 955H5M | 191 | 955 | |

| 960H5M | 192 | 960 | |

| 965H5M | 193 | 965 | |

| 975H5M | 195 | 975 | |

| 980H5M | 196 | 980 | |

| 985H5M | 197 | 985 | |

| 1000H5M | 200 | 1000 | |

| 1015H5M | 203 | 1015 | |

| 1020H5M | 204 | 1020 | |

| 1025H5M | 205 | 1025 | |

| 1035H5M | 207 | 1035 | |

| 1050H5M | 210 | 1050 | |

| 1075H5M | 215 | 1075 | |

| 1080H5M | 216 | 1080 | |

| 1100H5M | 220 | 1100 | |

| 1110H5M | 222 | 1110 | |

| 1125H5M | 225 | 1125 | |

| 1135H5M | 227 | 1135 | |

| 1140H5M | 228 | 1140 | |

| 1145H5M | 229 | 1145 | |

| 1150H5M | 230 | 1150 | |

| 1160H5M | 232 | 1160 | |

| 1175H5M | 235 | 1175 | |

| 1180H5M | 236 | 1180 | |

| 1190H5M | 238 | 1190 | |

| 1195H5M | 239 | 1195 | |

| 1200H5M | 240 | 1200 | |

| 1210H5M | 242 | 1210 | |

| 1225H5M | 245 | 1225 | |

| 1235H5M | 247 | 1235 | |

| 1250H5M | 250 | 1250 | |

| 1270H5M | 254 | 1270 | |

| 1295H5M | 259 | 1295 | |

| 1310H5M | 262 | 1310 | |

| 1340H5M | 268 | 1340 | |

| 1350H5M | 270 | 1350 | |

| 1380H5M | 276 | 1380 | |

| 1390H5M | 278 | 1390 | |

| 1400H5M | 280 | 1400 | |

| 1420H5M | 284 | 1420 | |

| 1455H5M | 291 | 1455 | |

| 1490H5M | 298 | 1490 | |

| 1500H5M | 300 | 1500 | |

| 1520H5M | 304 | 1520 | |

| 1530H5M | 306 | 1530 | |

| 1540H5M | 308 | 1540 | |

| 1575H5M | 315 | 1575 | |

| 1595H5M | 319 | 1595 | |

| 1635H5M | 327 | 1635 | |

| 1690H5M | 338 | 1690 | |

| 1700H5M | 340 | 1700 | |

| 1720H5M | 344 | 1720 | |

| 1760H5M | 352 | 1760 | |

| 1800H5M | 360 | 1800 | |

| 1870H5M | 374 | 1870 | |

| 1875H5M | 375 | 1875 | |

| 1895H5M | 379 | 1895 | |

| 1900H5M | 380 | 1900 | |

| 1945H5M | 389 | 1945 | |

| 2000H5M | 400 | 2000 | |

| 2050H5M | 410 | 2050 | |

| 2100H5M | 420 | 2100 | |

| 2250H5M | 450 | 2250 | |

| 2350H5M | 470 | 2350 | |

| 2460H5M | 492 | 2460 | |

| 2500H5M | 500 | 2500 | |

| 2525H5M | 505 | 2525 | |

| 2650H5M | 530 | 2650 | |

| 2670H5M | 534 | 2670 | |

| 2730H5M | 546 | 2730 | |

| 2760H5M | 552 | 2760 | |

| 2800H5M | 560 | 2800 | |

| 2850H5M | 570 | 2850 | |

| 3060H5M | 612 | 3060 | |

| 3070H5M | 614 | 3070 | |

| 3255H5M | 651 | 3255 | |

| 3360H5M | 672 | 3360 | |

| 3470H5M | 694 | 3470 | |

| 3660H5M | 732 | 3660 | |

| 3770H5M | 754 | 3770 | |

| 4260H5M | 852 | 4260 |