Linear Bushings Double Liner Standard

Caution

- - This product focuses on price competitiveness, and the unit price is low, but there may be rust, scratches, or scratches on the exterior. For those who place importance on product appearance, we recommend purchasing existing Misumi products rather than economy products. - If domestic stock is insufficient, the minimum order quantity may be temporarily increased. we ask For your understanding. - Due to the retainer color change (existing: black, changed: yellow), the color may differ from the representative image, and colors may be mixed and shipped.

- This product will be discontinued once stock ran out. The replacement model CLICK here

Product Description

Linear Bushings Double Liner Standard

These Linear Bushings are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

● Support Shaft Diameter Minimum/Maximum (mm.): 6 and 30

● Overall Length Minimum/Maximum (mm.): 35 and 123

● Shape : Straight

● Material:

- Housing - SUJ2 Equivalent

- Ball - SUJ2 Equivalent

[Application]

It is used in industrial machinery such as conveyor systems, packaging machines, and robotic equipment.

Economy Double Liner Standard Linear Bushing

- Cost-effective double liner bushing for heavy-duty applications.

- Low noise and high durability for smooth operation.

- Supports a range of shaft diameters

- Electroless nickel plating option for enhanced rust prevention.

- Perfect for industrial machinery and packaging machines.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Linear Bushings Product Overview

Through the rolling of steel ball, high-efficiency movement with low friction resistance can be realized.

Linear Bushings Product Feature

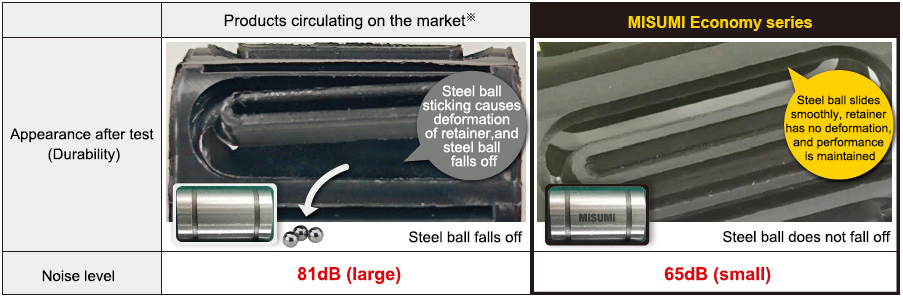

Feature 2: Holding high durability, low noise

■ Test conditions

• Linear Bushings (inner diameter 16) is matched with MISUMI guide shaft (PSFJ) to apply 63kg load and walk for 30km, and confirm the product damage and sliding noise.

■ Test results

The economy series product ensures smooth sliding of steel ball, which have good durability and low noise

*Products circulating on the market are similar products randomly purchased by our company from online or offline markets

*The test data are obtained through testing by our company, which are for reference only

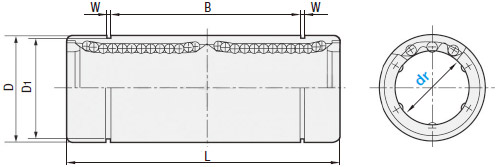

Dimensional Linear Bushings Drawing

This product is delivered at the initial stage, the color of the packing may be inconsistent with the photo, which shall be subject to the actual product.

This product is delivered at the initial stage, the color of the packing may be inconsistent with the photo, which shall be subject to the actual product.Linear Bushings Specifications Overview

| Type | dr[Φ:mm] | Housing | Ball | Retainer | Operating environment temperature |  Accessories Accessories | ||

Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Material Material | ||||

| C-LM__LUU | 6~30 | Equivalent to SUJ2 | 58HRC~ | - | Equivalent to SUJ2 | Resin | -20~80℃ | Seal packing Material MaterialNitrile Rubber |

If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating or those with low temperature hard chromium plating.

If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating or those with low temperature hard chromium plating.Linear Bushings Usage Method

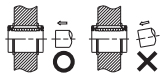

| Product Drawings | Instructions for use |

| When the linear bearing is under heavy load (unbalanced load), one piece of single liner type is not applicable. It is recommended to use one piece of double liner type or multiple pieces of single liner type. |

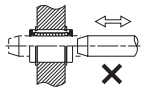

| Linear Bushings is not suitable for rotating motion in structure. If you rotate forcibly, it may cause damage to the product. Please pay attention during use. |

| Linear Bushings is not suitable for repeated plugging and unplugging. |

| When inserting the guide shaft into the linear bearing, please align the center and insert it slowly, otherwise the steel ball will fall off or the retainer will be deformed. |

Linear Bushings Precautions

① Linear Bushings Before use, please apply grease to the ball row inside the linear bearing, and then replenish it in due course. Grease forms an oil film on the surfaces of steel ball and rolling surface (guide shaft·bushing) of linear bearing, which effectively reduces friction and prevents sintering. Grease reduction and aging will greatly affect the life of linear bearing.

② Recommended grease: lithium soap grease.

③ Recommended grease filling interval: Usually every 6 months.

When the moving distance is long, it is recommended to move once every three months or when the moving distance exceeds 1000km within the time limit, the 1000km shall prevail.

■ Dust prevention measures:

If dust or foreign matter enters the inside of the linear bearing, it may damage the circulation of steel balls, resulting in unexpected failures. When used in harsh environment, please install dust cover and protection cover, etc.

■ MISUMI linear bearing is recommended to be combined with guide shaft with quenching g6 tolerance.

■ MISUMI linear bearing is recommended to be installed on the holder with H7 tolerance. The linear bearing is in clearance fit with the holder.

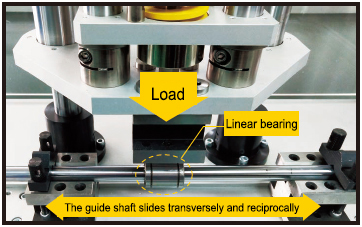

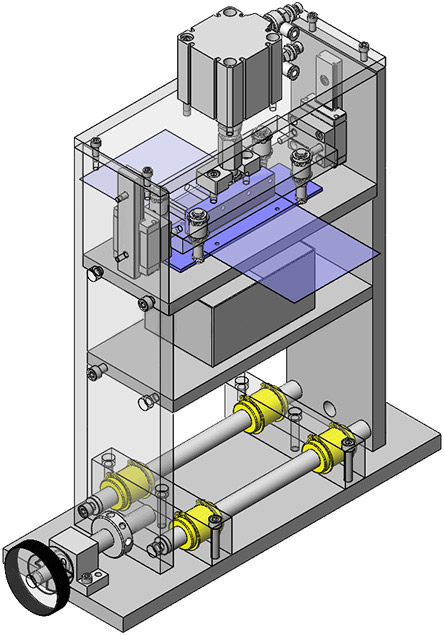

Example of Use Linear Bushings

Stamping die position adjustment component

Design Purpose:

Adjust the position of the stamping die to correct the deviation of the opening position in the width direction of the sheet workpiece.

Application Description:

By matching with the cylinder, it realizes the guidance of the linear motion of the workpiece in the horizontal direction.

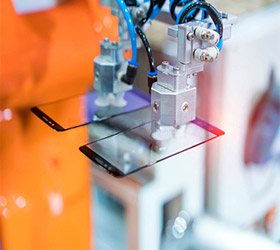

Linear Bushings Application Industries

| Electronic & Electrical Appliances | Automotive | Lithium battery | ||

|  |  | ||

| LCD | Smart phone | Semiconductor | ||

|  |  |

Linear Bushings Related Products

| Guide shaft Straight bar type | Linear bearing holder assembly Block widened double liner type | Linear bearing Standard type Straight type | ||

|  |  | ||

| Typical model: SFJ20-75 | Typical model: LHBBW8 | Typical model: LMUW8 |

| Part Number | |||

| C-LM16LUU | ||||

■Material Specification Table

| Type | Housing | Ball | Retainer | Operating environment temperature |  Accessories Accessories | ||

Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Material Material | |||

| C-LM__LUU | Equivalent to SUJ2 | 58HRC~ | - | Equivalent to SUJ2 | Resin | -20~80℃ | Seal packing Material MaterialNitrile Rubber |

■ Dimension Specification Table

| Part Number | D | L | B | W | D1 | Lateral Misalignment (maximum) | Number of ball rows | Weight (g) | Basic Rated Load | Static allowable torque (N·m) | ||||||

| Type | dr | Tolerance | Tolerance | Tolerance | Tolerance | C (Dynamic) N | Co (Static) N | |||||||||

| C-LM__LUU | 6 | +0.003 -0.012 | 12 | 0 -0.015 | 35 | +0.3 -0.6 | 24.8 | 0 -0.4 | 1.1 | 11.5 | 0.03 | 4 | 14 | 324 | 529 | 2.18 |

| 8 | 15 | 45 | 32.8 | 14.3 | 25 | 431 | 784 | 4.31 | ||||||||

| 10 | 19 | 55 | 41.4 | 1.3 | 18 | 48 | 588 | 1100 | 7.24 | |||||||

| 12 | 21 | 0 -0.018 | 57 | 43.4 | 20 | 52 | 657 | 1200 | 10.9 | |||||||

| 16 | 28 | 70 | 49.8 | 1.6 | 27 | 5 | 141 | 1230 | 2350 | 19.7 | ||||||

| 20 | +0.003 -0.013 | 32 | 0 -0.021 | 80 | 57.8 | 30.5 | 0.04 | 161 | 1400 | 2740 | 26.8 | |||||

| 25 | 40 | 112 | +0.3 -0.7 | 78.3 | 0 -0.5 | 1.9 | 38 | 6 | 402 | 1560 | 3140 | 43.4 | ||||

| 30 | 45 | 123 | 85.3 | 43 | 448 | 2490 | 5490 | 82.8 | ||||||||

If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating or those with low temperature hard chromium plating.

If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating or those with low temperature hard chromium plating. For adjusting ring for linear bearing, linear bearing stopper.

For adjusting ring for linear bearing, linear bearing stopper.