Collars

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part21 CLICK here

Product Description

・ Product type: Metal collars, C-KNCLA series.

・ Metal Washers and Collars are commonly used as cushioning components at workpiece connectors, adjusting clearances. Available in various combinations of inner and outer diameters and lengths, including 10mm, 12mm, 15mm, 20mm, and 30mm.

・ Outer diameter [mm]: 5, 6, 8, 10, 12, 15, 20, 25, 30

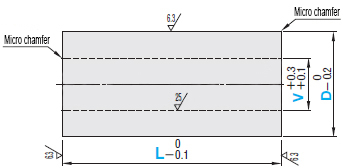

・ Tolerance: I.D. Tolerance +0.3 ~ +0.1, Thickness / Length 0 ~ -0.1, O.D. Tolerance

・ This is an economy item; The price is cheaper than the MISUMI standard product.

Economy Collars

- Cost-effective metal collars designed for accurate cushioning and clearance adjustment.

- Available in a range of outer, inner diameters, and thicknesses to fit various applications.

- Made from durable materials with enhanced durability and corrosion resistance.

- Ideal for precise positioning, securing components while providing support.

- Ready for same-day shipping for timely delivery.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview of Metal Washers, Collars

Product Feature of Metal Washers, Collars

Feature of Metal Washers, Collars 2: Simple structure, reliable positioning, wide range of uses

① It can be used to ensure the relative position between two timing pulley workpieces

② Metal Washers, Collars can be used for limiting the position of the linear parts or fixed parts on the shaft

③ Can be matched with screws to control the relative clearance between the sheet metal and the support

Feature 3: Surface treatment is trivalent chromate, good corrosion resistance

Dimensional Drawing of Metal Washers, Collars

Specifications Overview of Metal Washers, Collars

| Type of Metal Washers, Collars |  Material Material |  Surface Treatment Surface Treatment | D(mm) | V (mm) | T (mm) |

| C-KNCLA | General structural steel or carbon steel | Trivalent Chromate Treatment | 3~25 | 5~30 | 10~30 |

The surface of this product is barrel-plated, so the appearance may have some bumps and bruises.

The surface of this product is barrel-plated, so the appearance may have some bumps and bruises.Usage Method of Metal Washers, Collars

| Diagram of Metal Washers, Collars | Instructions |

| Metal Washers, Collars can be used to ensure the relative position between two timing pulley workpieces. | |

| Metal Washers, Collars can be used for limiting the position of the linear parts or fixed parts on the shaft. | |

| Metal Washers, Collars Can be matched with screws to control the relative clearance between the sheet metal and the support. |

Example Use of Metal Washers, Collars

Different fixtures used according to the frequency of process switching.

■Mechanism function

Because of the use of fast-fixing parts and replaceable positioning parts, it can be used as a support fixture for a variety of workpieces.

■Role of Metal Washers, Collars

A Metal Washers, Collars is placed on the fixed surface of the toggle clamp to limit the height of the toggle clamp. For workpieces of different thicknesses, a variety of metal collars of different lengths can be replaced.

Related Industries of Metal Washers, Collars

| Smart phone | Electronic & Electrical Appliances | Lithium battery | ||

| Automotive | Robotics | Medical | ||

Precautions of Metal Washers, Collars

② The surface of this product is barrel plated, so the appearance may have some bumps and bruises.

③ This product is processed with micro-chamfering, and the specific size of the chamfer is not guaranteed.

Related Products of Metal Washers, Collars

| Economy series Metal Washers, Collars Standard grade | Ultra short head hex socket bolt | Adjustment Screw Components Hex Head Stud | ||

|  |  | ||

| Typical model of Metal Washers, Collars: C-WSSA10-3-1 | Typical model of Metal Washers, Collars: CBSA6-12 | Typical model of Metal Washers, Collars: ANH4-20 |

Specification Table of Metal Washers, Collars

to

to  .

. | Part Number ( Type· Type· V) V) | - |  D D | - |  L L | |

| C-KNCLA3 | - | 5 | - | 10 |

| Part Number |  D DSelection |  L LSelection | |||||||||||||

Type Type |  V V | ||||||||||||||

| C-KNCLA | 3 | 5 | 6 | 8 | 10 | ||||||||||

| 4 | 6 | 8 | 10 | 10 | 12 | 15 | |||||||||

| 5 | 8 | 10 | 12 | 10 | 12 | 15 | |||||||||

| 6 | 8 | 10 | 12 | 10 | 12 | 15 | |||||||||

| 15 | 20 | 10 | 12 | 15 | 20 | ||||||||||

| 8 | 10 | 12 | 15 | 20 | 10 | 12 | 15 | 20 | |||||||

| 10 | 12 | 15 | 20 | 10 | 15 | 20 | |||||||||

| 12 | 15 | 20 | 10 | 15 | 20 | ||||||||||

| 15 | 20 | 10 | 15 | 20 | |||||||||||

| 20 | 25 | 30 | 10 | 15 | 20 | ||||||||||

| 25 | 30 | 10 | 15 | 20 | 30 | ||||||||||