Miniature Cam Followers

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

・ Product type: Miniature Cam Followers, C-CF / C-CFS series.

・ Roller material: Made of Stainless steel SUS440 (C-CFS) or SUJ2 (C-CF)

・ Outer roller diameter D (Ø) [mm]: 4.5, 5, 6, 8, 10, 12

・ Roller width B [mm]: 2.5, 3, 4, 5, 6, 7

・ Stud Screw Nominal size: M2 x 0.4, M2.5 x 0.45, M3 x 0.5, M4 x 0.7, M5 x 0.8, M6 x 1

・ This is an economy item; The price is cheaper than the MISUMI standard product.

Economy Miniature Cam Followers

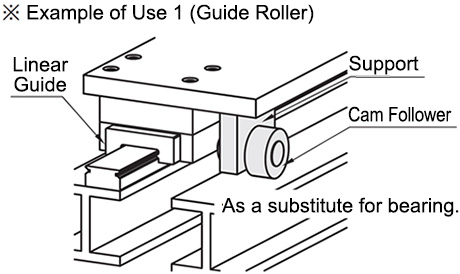

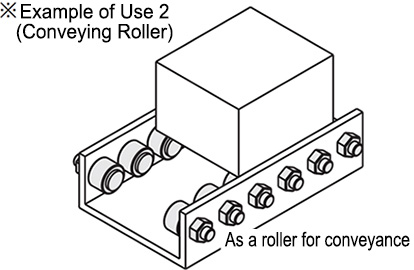

- Miniature size for space-constrained applications. Available with various outer roller diameters.

- Multiple roller widths available. Choose from widths within specified range.

- Suitable for high-speed rotations. Engineered to handle high-speed operations, ideal for applications requiring rapid movement.

- Available in standard and full complement roller types. Standard type for low friction and high-speed applications; full complement type for heavy load-bearing capabilities

- Constructed from SUS440 or SUJ2 stainless steel. Offers excellent corrosion resistance and durability, suitable for harsh environments and clean rooms.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

A cam follower is a high-performance shaft-type bearing with needle-shaped rollers, known as needle rollers, assembled inside. The needle rollers enhance rotational capability and can withstand high-speed rotation. In addition, the outer ring features a thicker wall design compared to standard bearings, making it suitable for applications subject to impact loads or heavy loads.

Note: For some models, the packaging method has changed from box to bag. During the transition period, mixed shipments may occur, but this does not affect usage.

Note: The shaft of the miniature cam follower is relatively thin. Please tighten strictly according to the specified tightening torque; otherwise, there is a risk of shaft breakage.

Material Specifications

| Application | TYPE |  Material Material |  Accessories Accessories |

| General type | C-CF | Equivalent to SUJ2 (Cylindrical bolt section: SCM415) | 1 hex nut |

| C-CFS | Equivalent to SUS440 | 1 hex nut (SUS304) | |

| Low dust generation | E-CFFAMC | Equivalent to SUS440 | 1 hex nut (SUS304) |

| Heavy-duty type | E-CFFANG | Equivalent to SUJ2 (Columnar bolt section: SCM425) | 1 hex nut (S45C · magnetite protective film) |

| E-CFFAMG | Equivalent to SUS440 | 1 hex nut (SUS304) |

| Type |  Roller Outer Diameter D | Outer Diameter D Tolerance | M × Pitch | Roller Width B | B1 | L | ℓ | *H | |

Type Type |  d d | ||||||||

| C-CF C-CFS E-CFFAMC E-CFFANG E-CFFAMG | 2 | 4.5 | 0 -0.008 | 2 × 0.4 | 2.5 | 4 | 8 | 2 | 0.9 |

| 2.5 | 5 | 2.5 × 0.45 | 3 | 4.5 | 9.5 | 2.5 | |||

| 3 | 6 | 3 × 0.5 | 4 | 5.5 | 11.5 | 3 | 1.3 | ||

| 4 | 8 | 4 × 0.7 | 5 | 7 | 15 | 4 | 1.5 | ||

| 5 | 10 | 5 × 0.8 | 6 | 8 | 18 | 5 | 2 | ||

| 6 | 12 | 6 × 1.0 | 7 | 9.5 | 21.5 | 6 | 2.5 | ||

E-CFFAMC, E-CFFANG, and E-CFFAMG do not have d=2 specifications for now

E-CFFAMC, E-CFFANG, and E-CFFAMG do not have d=2 specifications for now■ Parameter Table

| d | Basic Rated Load | Maximum Static Allowable Load | Maximum Locking Torque (N·cm) | ||||||||||

| C-CF | C-CFS | E-CFFANG | E-CFFAMG/E-CFFAMC | C-CF (N) | C-CFS (N) | E-CFFAMG E-CFFAMC (N) | E-CFFANG (N) | ||||||

| Cr (Dynamic) N | Cor (Static) N | Cr (Dynamic) N | Cor (Static) N | Cr (Dynamic) N | Cr (Static) N | Cr (Dynamic) N | Cor (Static) N | ||||||

| 2 | 188 | 132 | 168 | 113 | — | — | — | — | 118 | 101 | — | — | 10 |

| 2.5 | 254.2 | 207.7 | 217 | 176.7 | 800 | 864 | 736 | 792 | 176.7 | 176.7 | 187.2 | 208 | 20 |

| 3 | 390.6 | 378.2 | 350.3 | 325.5 | 1096 | 1416 | 1008 | 1296 | 325.5 | 325.5 | 326.5 | 342 | 30 |

| 4 | 669.6 | 669.6 | 567.3 | 567.3 | 1880 | 2432 | 1728 | 2232 | 567.3 | 567.3 | 592.8 | 624 | 60 |

| 5 | 973.4 | 1153.2 | 830.8 | 868 | 2512 | 3768 | 2304 | 3464 | 868 | 868 | 965.6 | 1136 | 130 |

| 6 | 1277.2 | 1339.2 | 1165.6 | 1264.8 | 3688 | 5016 | 3392 | 4608 | 1264.8 | 1264.8 | 1434.8 | 1688 | 230 |

kgf = N × 0.101972

kgf = N × 0.101972■ Note

1. The low dust generation type cam follower is filled with low dust generation grease AFE-CA (THK). Its performance and operating temperature are as follows.

| Thickener | Urea-based compound |

| Base oil | Synthetic oil |

| Base oil kinematic viscosity (40°C, mm2/s) | 100 |

| Worked penetration (25°C·60W) | 260 |

| Dropping point (°C) | 258 |

| Evaporation: wt% (99°C·22h) | 0.1 |

| Oil separation: wt% (100°C·22h) | 0.8 |

| Operating temperature (°C) | -40 to +160 (atmospheric environment) |

2. Ideal for load-bearing applications!

3. Also suitable for high-speed rotation!

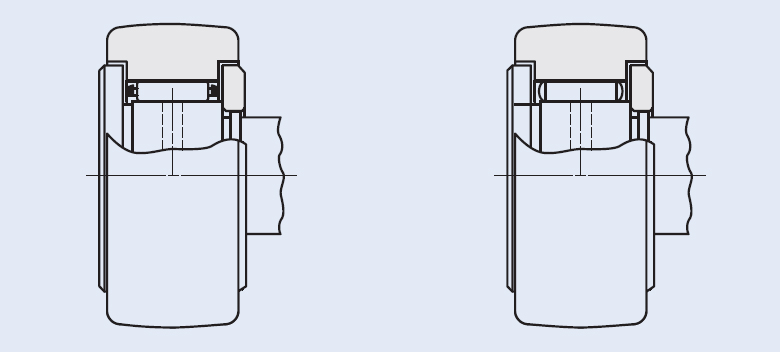

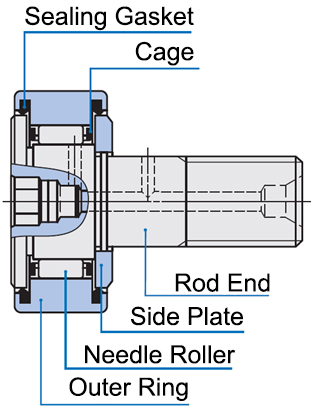

Standard Cam Follower Structure

Roller Guidance Method

Cam followers with cages are suitable for applications requiring low friction and high speed, while full complement cam followers are suitable for high-speed rotation and heavy load applications.

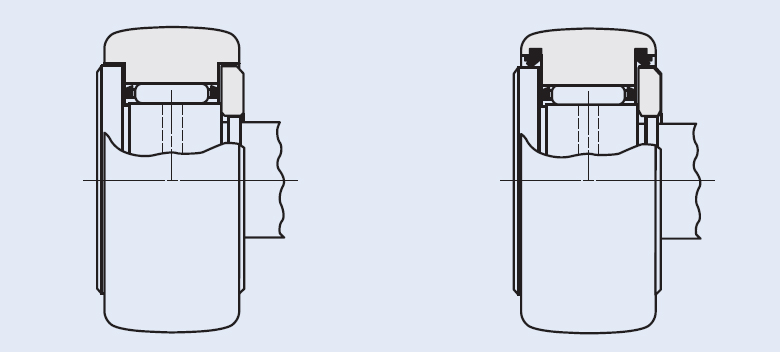

Seal structure

In non-sealed bearings, the gap between the outer ring and the end rod circumferential area, as well as between the outer ring and the side plate, is small, forming a labyrinth. In sealed bearings, a sealing gasket is installed in the shielded labyrinth section to prevent foreign matter from entering.

Please note: The threaded section of miniature cam follower bearings is of a small diameter.

To prevent damage, do not exceed the maximum tightening torque when installing with a wrench.

(The maximum tightening torque is approximately one-fourth that of a standard bolt. Please be aware of this.)

· When subjected to impact, even if there is no visible damage, functionality may still be impaired. Please take note.

· Cam followers are suitable for radial loads and are not well suited for thrust loads. Therefore, please avoid using them in applications that apply thrust loads.

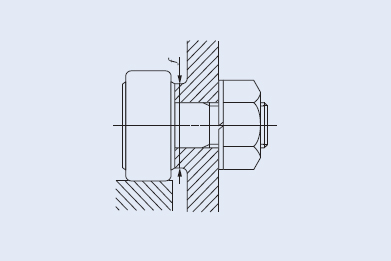

Installation Method

When installing, do not strike the flange of the cam bearing directly with a hammer, as this may cause poor rotation or breakage. Please use a hex wrench or a flathead screwdriver.

Secure the hex socket or screwdriver slot, then use a wrench to tighten the nut.